Cabinet slot position monitoring method based on indoor light source and method for positioning equipment in cabinet

A cabinet and slot technology, which is applied in the field of cabinet monitoring and equipment positioning, can solve problems such as inconvenient installation, small cabinet space, and signal interference, and achieve the effects of convenient maintenance and replacement, reduced polling frequency, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] 1) Slot status monitoring

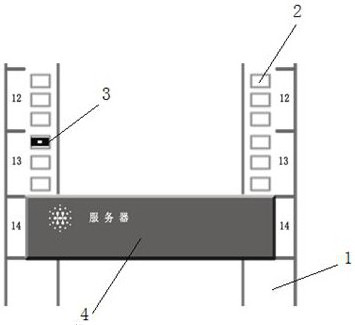

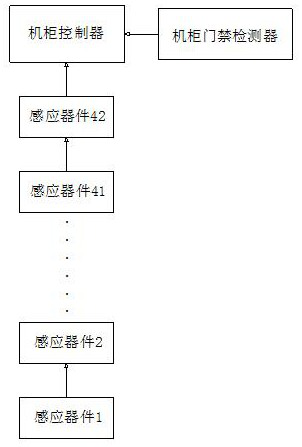

[0041] refer to figure 1 As shown in the figure, slots 12 to 14 on the equipment installation column 1 are shown. The equipment installation column 1 of the cabinet is provided with several equipment installation holes 2 for installing equipment panels, and each slot is divided into multiple slots. There are three equipment installation holes, generally three, that is, each slot generally corresponds to three equipment installation holes, and usually only one or at most two are used, so that at least one equipment installation hole will be vacated for the installation of photosensitive sensors 3. When equipment is installed on the slot, the equipment panel 4 will be fixed on the equipment installation hole, which will necessarily cover all the equipment installation holes of each slot.

[0042] A cabinet slot monitoring method based on an indoor light source, comprising the following steps:

[0043] Install corresponding photosensitive sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com