A high-voltage switchgear with defect monitoring and comprehensive control functions

A high-voltage switchgear and integrated control technology, applied in the field of high-voltage switchgear, can solve problems such as difficult integration, wrong analysis results, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

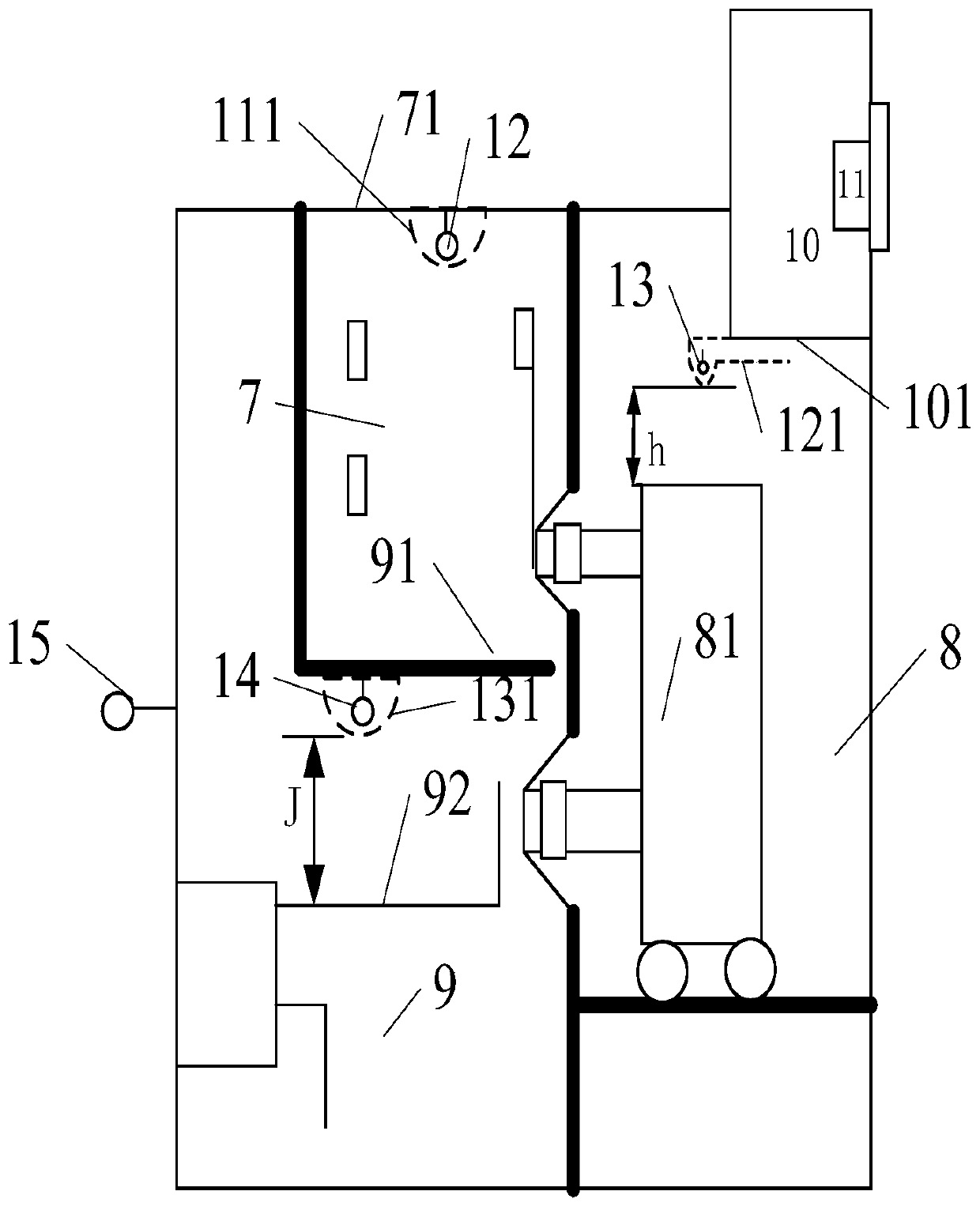

[0075] The structure of this embodiment 2 is basically the same as that of embodiment 1, the difference is that the measurement and control device 11 is also provided with 3 gas detection circuits, 3 ultrasonic detection circuits, 3 photoelectric detection circuits and corresponding sensors; there are 2 open circuits Coil current detection circuit and current sensor; 2 auxiliary switch action signal detection circuits; the measurement and control device 11 is also equipped with 2 switching output circuits 1DO and 2DO for controlling the entry and exit of the handcart of the circuit breaker; 2 circuits for controlling the operation of the grounding knife Switching output circuit 3DO, 4DO and 2 circuit breaker opening and closing position switching input circuit 1DI, 2DI, 2 circuit breaker working and testing position switching input circuit 3DI, 4DI, 2 grounding knife closing and opening position Switch value input circuit 5DI, 6DI, 1 route switch switching value input circuit 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com