Capacitor multi-range test fixture

A test fixture and multi-range technology, which is applied in the measurement of electrical variables, components of electrical measuring instruments, and electrical measurement, can solve the problems of inconvenient disassembly and debugging, inability to achieve compatibility, and affecting the production efficiency of processing manufacturers. High test efficiency, good test stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

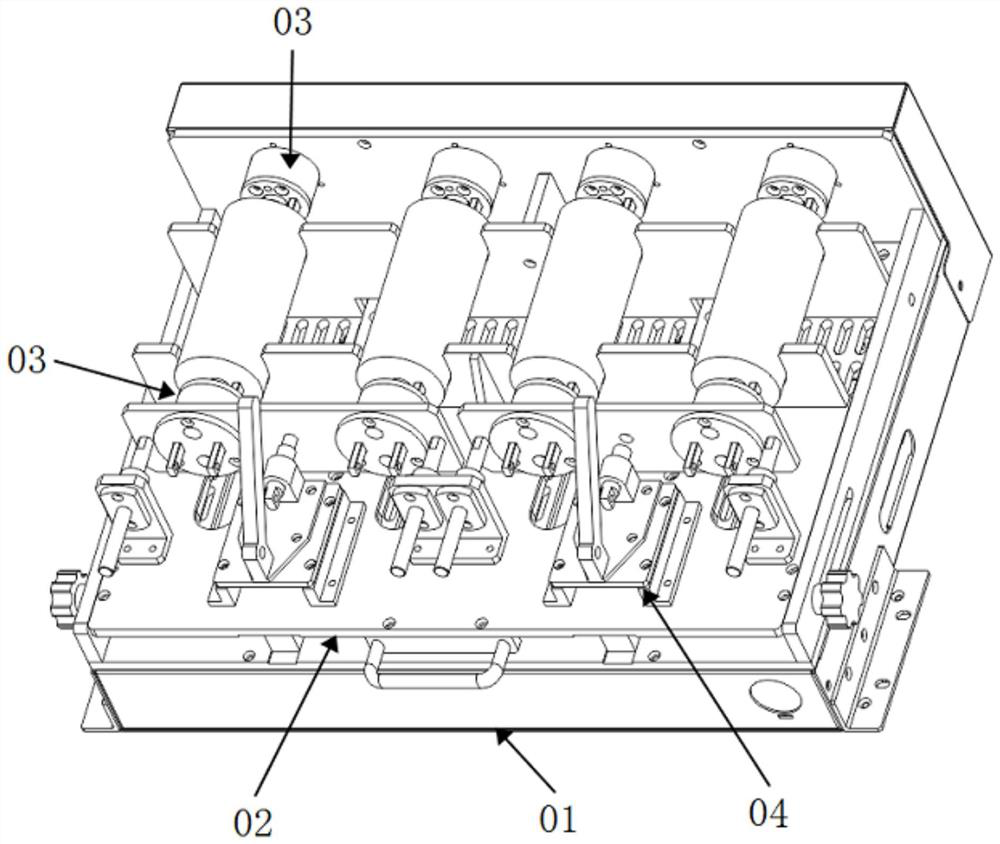

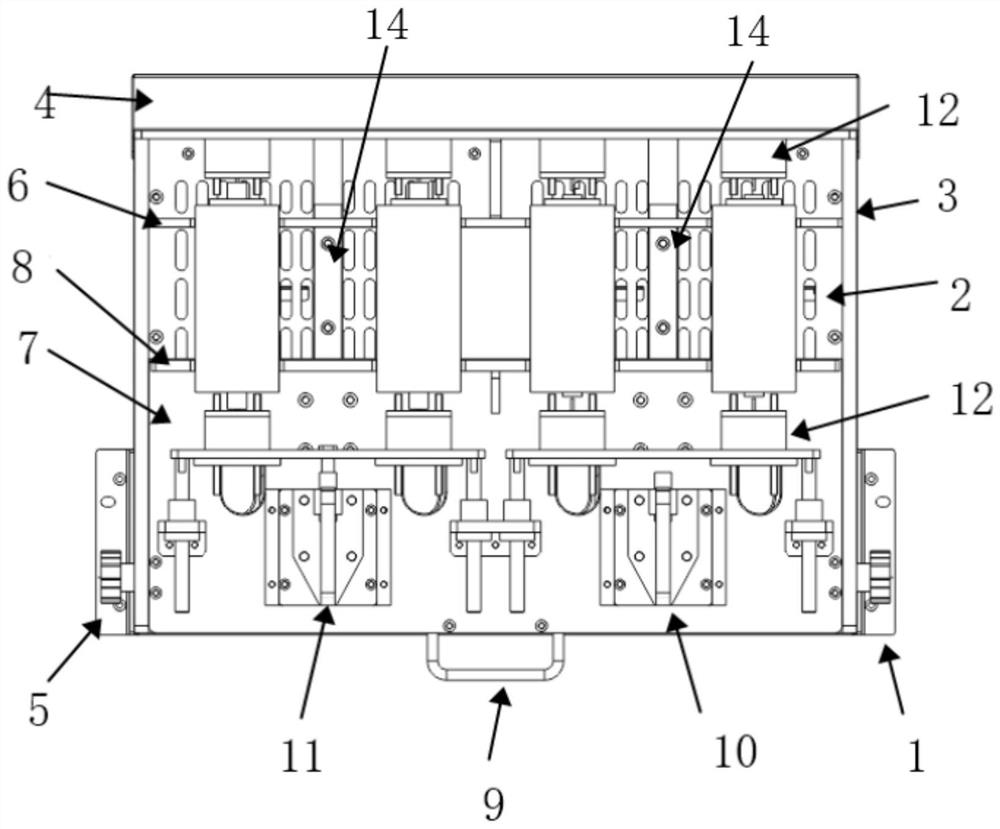

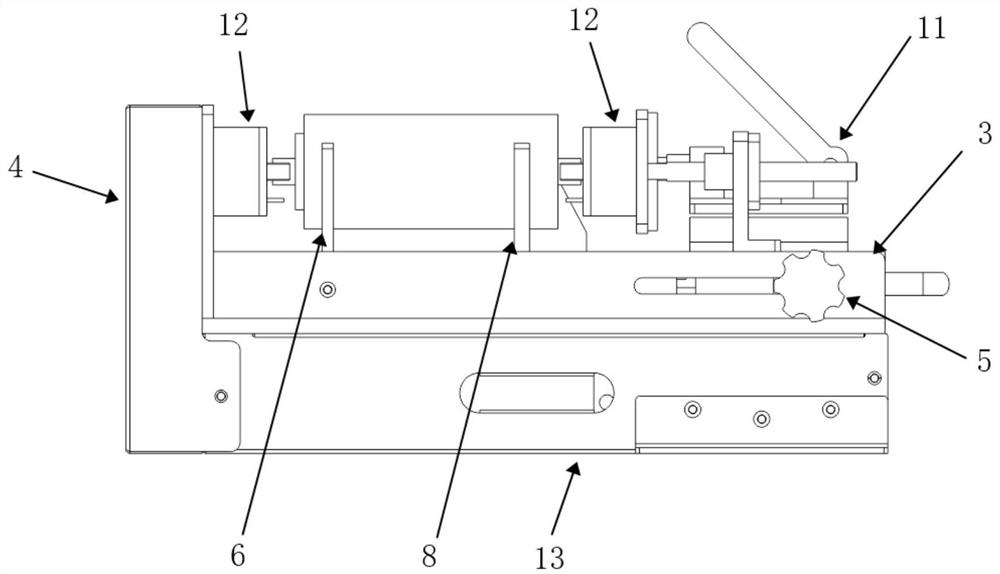

[0045] The embodiment of the present invention is realized like this, as figure 1 The capacitance multi-range test fixture shown includes:

[0046] Mounting seat 01;

[0047] Test bracket 02, used to place capacitors;

[0048] The test component 03 is used to test the capacitance;

[0049] The pressing component 04 is installed on the test bracket 02 and is used for adjusting the measuring range of the test component 03 .

[0050] In the actual application of the present invention, the mounting base 01 supports the test bracket 02, puts the capacitor on the test bracket 02, and then adjusts the range of the test component 03 by pressing the component 04, so as to adapt to capacitors of different specifications, and then Capacitors with different specifications can be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com