Real-time monitoring and maintaining system for oil filter of large hydraulic excavator

An oil filter, real-time monitoring technology, applied to the installation/connection of pressure lubricants, lubricant purification devices, lubricating parts, etc., can solve the problems of inability to detect filter element resistance, inability to determine filter element replacement standards, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

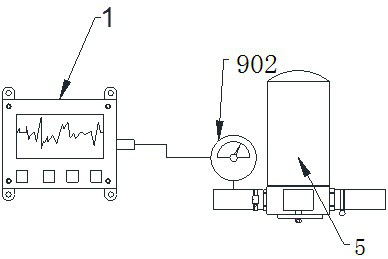

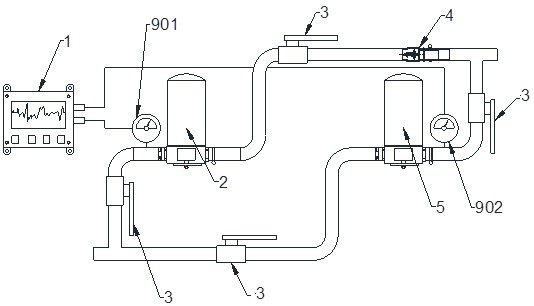

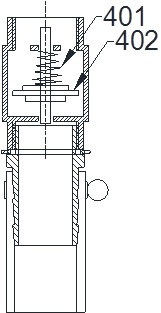

[0021] Such as Figure 1 to Figure 6 A large hydraulic excavator oil filter real-time monitoring and maintenance system shown includes an oil filter II5, and an oil flow detection device II902 is installed at the oil inlet or outlet of the oil filter 5. The oil flow detection device II 902 is connected with an oil filter real-time monitor 1 . The large hydraulic excavator oil filter real-time monitoring and maintenance system of the present invention includes an oil filter, an oil flow detection device is installed at the inlet or outlet of the oil filter, and the detection data is transmitted to the oil filter real-time monitor , The oil filter real-time monitor compares the flow data in its own database with the detection data, predicts the life of the oil filter, and displays it visually. The real-time monitoring and maintenance system of this application can detect the usage of the oil filter in real time and visualize the results. According to the detection results, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com