Gilling machine coiler tensioning device

A technology of tension device and sliver coiler, which is applied in deburring device, textile and paper making, fiber processing, etc. It can solve the problems of unstable tension, easy loosening of tensioning wheel, large tension fluctuation, etc., so as to prolong the service life and install Steady, smooth-moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

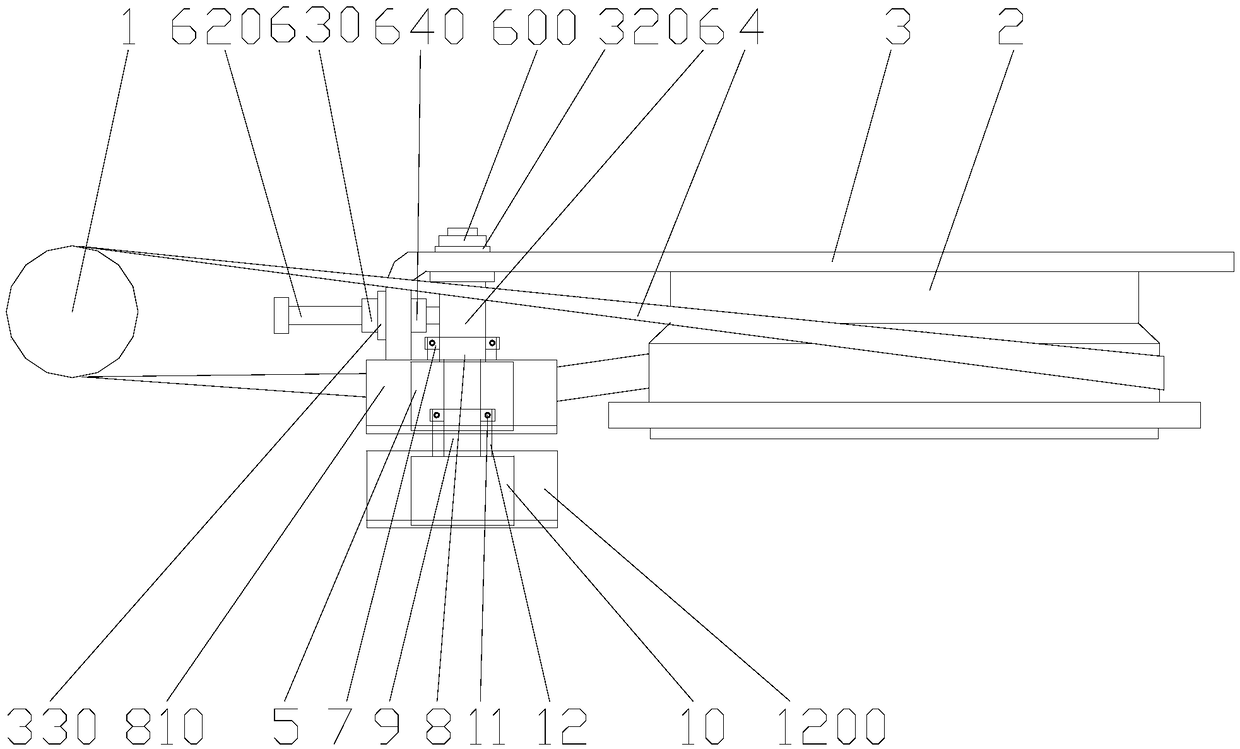

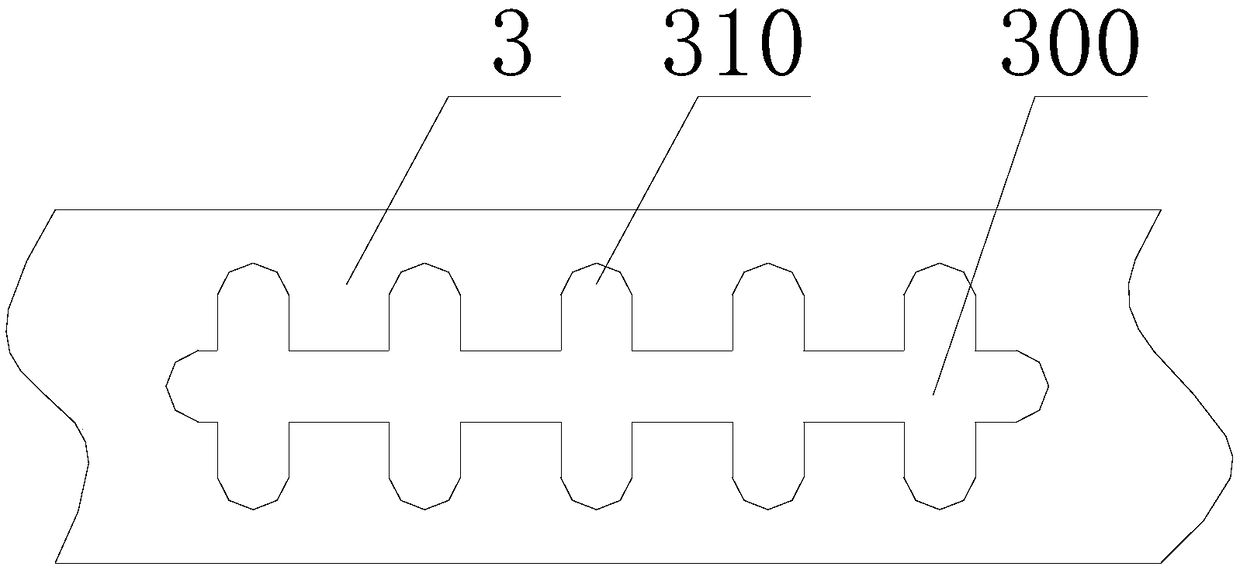

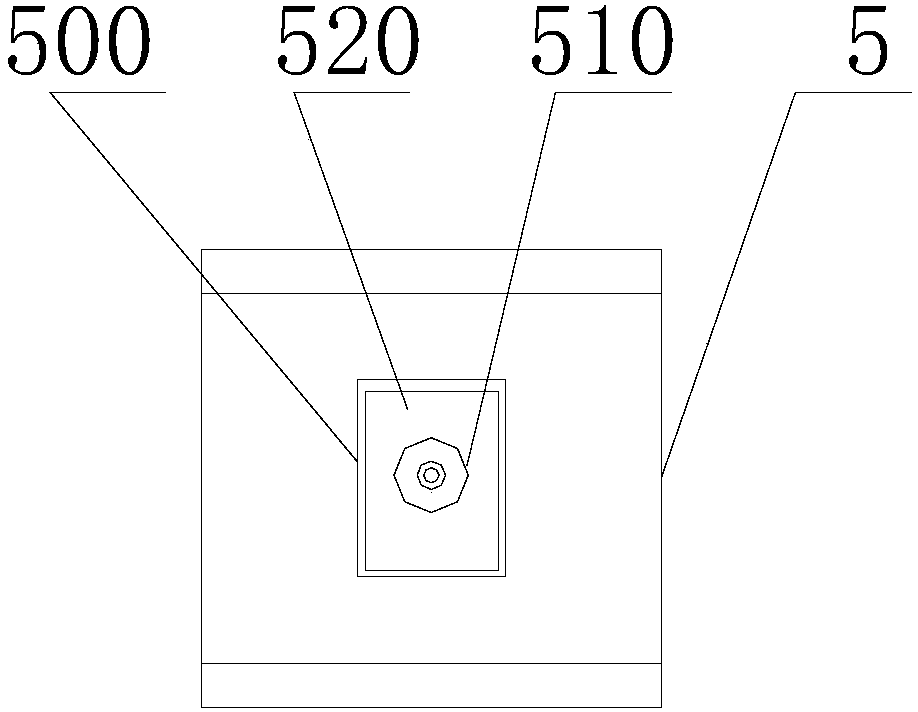

[0030] Such as Figure 1 to Figure 9As shown, the present invention provides a sliver coiler tension device for a needle carding machine, the tension device is installed in the sliver coiler, and the sliver coiler includes a driving wheel 1, a coiler disc 2 and a disc frame 3, the The driving wheel 1 and the coiling disc 2 are connected by a flat belt 4, and the coiler is rotatably installed in the disc frame 3, and the tensioning device includes a first tensioning wheel 5, and the first tensioning wheel 5 is close to the flat belt 4, and the first tensioning wheel 5 is threaded along the axial direction with a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com