Method and device for monitoring service life of gas purifier

A technology of gas purification and purifier, which is applied in the direction of chemical instruments and methods, measuring devices, and testing of machine/structural components, etc. It can solve the problems of fatal safety and hidden dangers, and achieve the effect of low cost and simple monitoring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

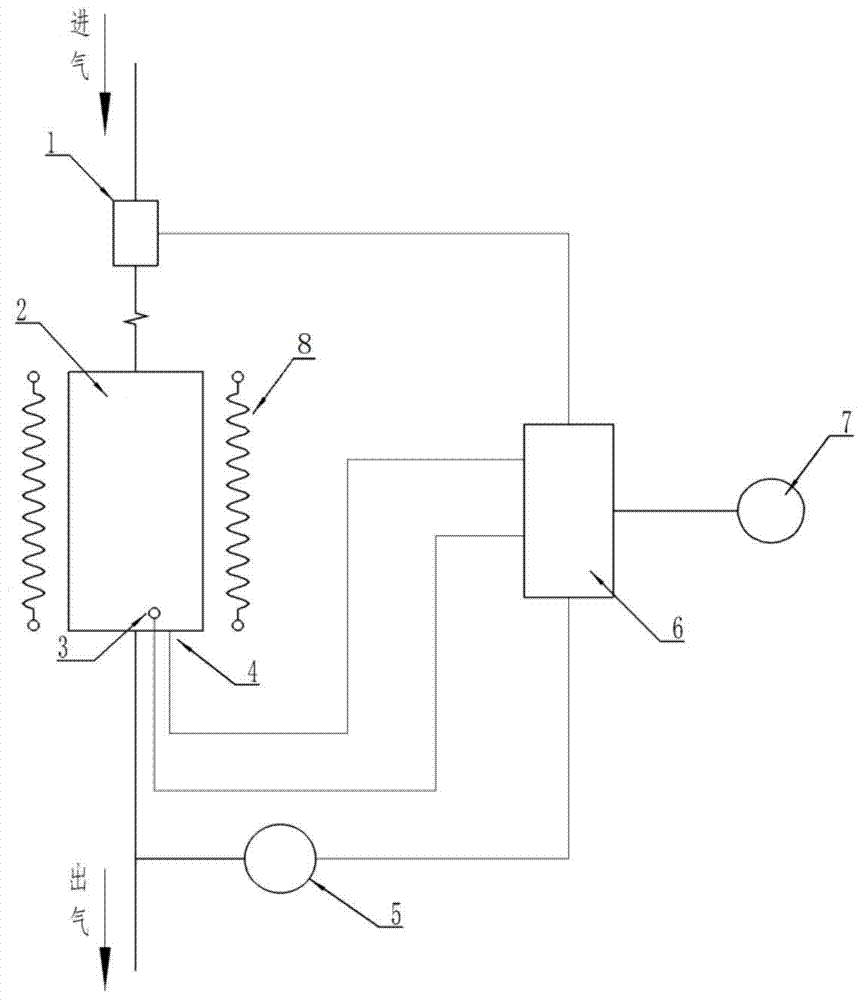

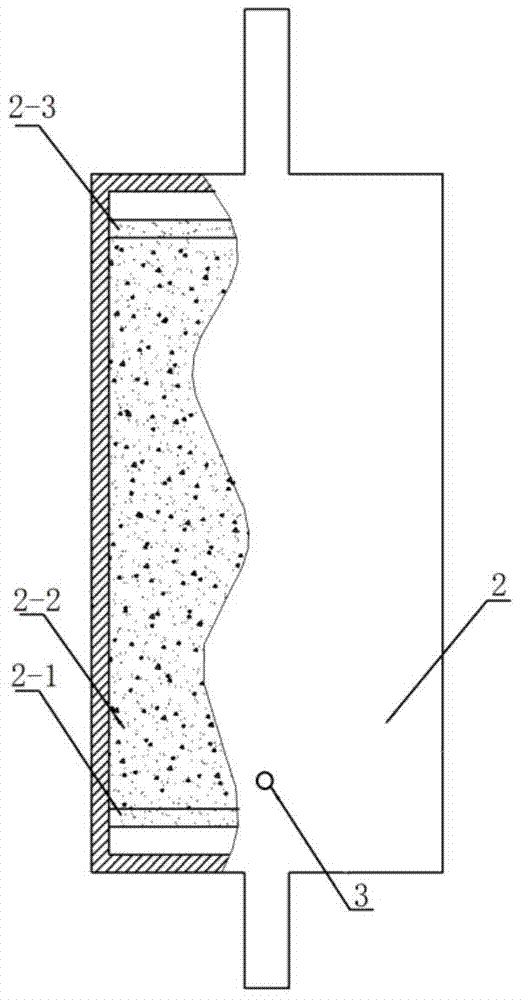

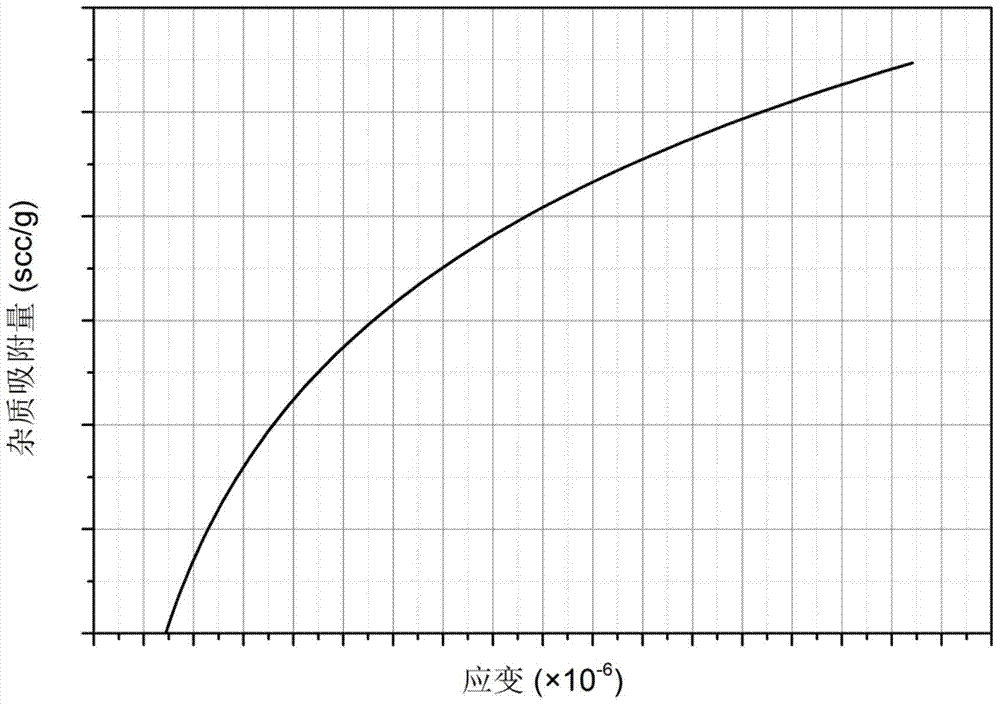

[0033] This embodiment is used to illustrate the method and device for monitoring the service life of the gas purifier in the present invention. The purifier reaction tank 2 has a diameter of 1.5mm and a length of 10cm. The loaded purification alloy filler 2-2 adopts the Ti17Zr16Mn40Cr13.5Ni13.5 purification material described in Chinese patent CN 103898389A, the particle size of the powder is -100 mesh, and the loading capacity is 50g. The structure of the monitoring device for the service life of the gas purifier and its purifier reaction tank 2 is as follows: Figure 1-2 As shown, the strain measurement uses a resistive strain gauge. The working pressure of the reaction tank 2 of the purifier is 0.5 MPa, the working temperature is 200° C., and the gas flow rate is 300 sccm. Containing 5000ppm O 2 Hydrogen was used as the raw material gas, and the gas purity was analyzed by GOW-MAC Company 592 DID gas chromatography, and the detection limit of impurity gas was 10ppb. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com