Mechanical fault predictive maintenance method and system based on knowledge graph

A knowledge map and mechanical failure technology, applied in the field of predictive maintenance of industrial clusters, can solve problems such as poor interpretability and large amounts of data, and achieve the effects of reducing equipment failure rates, high feasibility, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a mechanical fault predictive maintenance method based on knowledge graph;

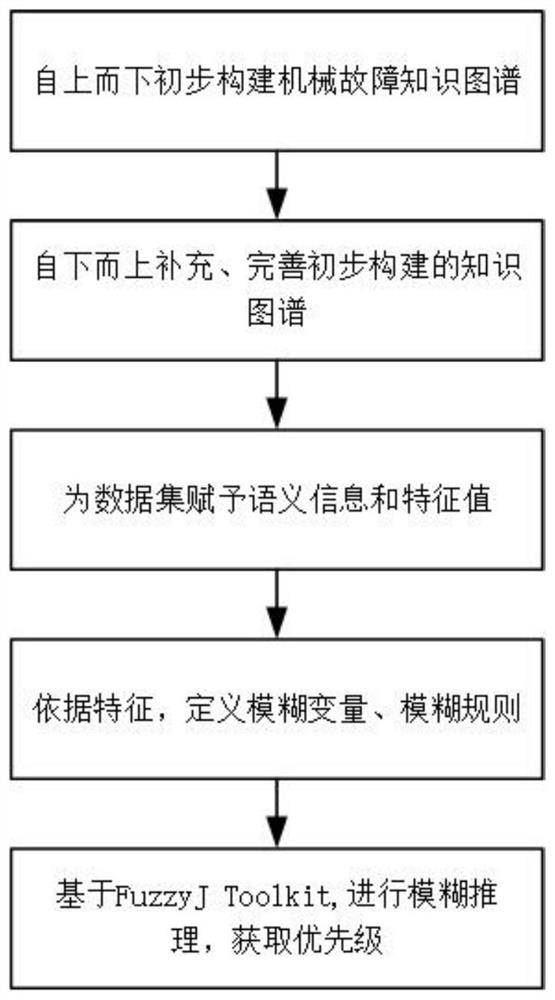

[0051] Such as figure 1 As shown, the predictive maintenance method for mechanical failure based on knowledge graph includes:

[0052] S101: Obtain the name of the mechanical equipment components to be maintained and the information of the mechanical equipment to be maintained; for the mechanical equipment to be maintained, initially build a knowledge graph of mechanical failure from top to bottom;

[0053] S102: Supplement and improve the preliminary construction of the mechanical fault knowledge map in a bottom-up manner;

[0054] S103: Select the corresponding data set for the mechanical equipment to be maintained; assign multiple features to each state of each component in the data set according to the supplemented mechanical fault knowledge map; wherein, each feature corresponds to a feature value;

[0055] S104: Define fuzzy variables, membership functions and f...

Embodiment 2

[0195] This embodiment provides a mechanical failure predictive maintenance system based on knowledge graph;

[0196] Mechanical failure predictive maintenance system based on knowledge graph, including:

[0197] The obtaining module is configured to: obtain the name of the mechanical equipment part to be maintained and the information of the mechanical equipment to be maintained; construct a mechanical fault knowledge map from top to bottom for the mechanical equipment to be maintained;

[0198] The supplementary module is configured to: supplement and improve the initially constructed mechanical fault knowledge map in a bottom-up manner;

[0199] The feature assignment module is configured to: select the corresponding data set for the mechanical equipment to be maintained; assign multiple features to each state of each component in the data set according to the supplementary mechanical fault knowledge map; wherein, each A feature corresponds to an eigenvalue;

[0200] A ru...

Embodiment 3

[0206] This embodiment also provides an electronic device, including: one or more processors, one or more memories, and one or more computer programs; wherein, the processor is connected to the memory, and the one or more computer programs are programmed Stored in the memory, when the electronic device is running, the processor executes one or more computer programs stored in the memory, so that the electronic device executes the method described in Embodiment 1 above.

[0207] It should be understood that in this embodiment, the processor can be a central processing unit CPU, and the processor can also be other general-purpose processors, digital signal processors DSP, application specific integrated circuits ASIC, off-the-shelf programmable gate array FPGA or other programmable logic devices , discrete gate or transistor logic devices, discrete hardware components, etc. A general-purpose processor may be a microprocessor, or the processor may be any conventional processor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com