Keel structure with variable bending rigidity

A bending stiffness and keel technology, which is applied in the field of keel structures for medical devices, can solve the problems of small stiffness variation range, poor applicability, and slow response speed, and achieve the effects of fast response speed, automatic control, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

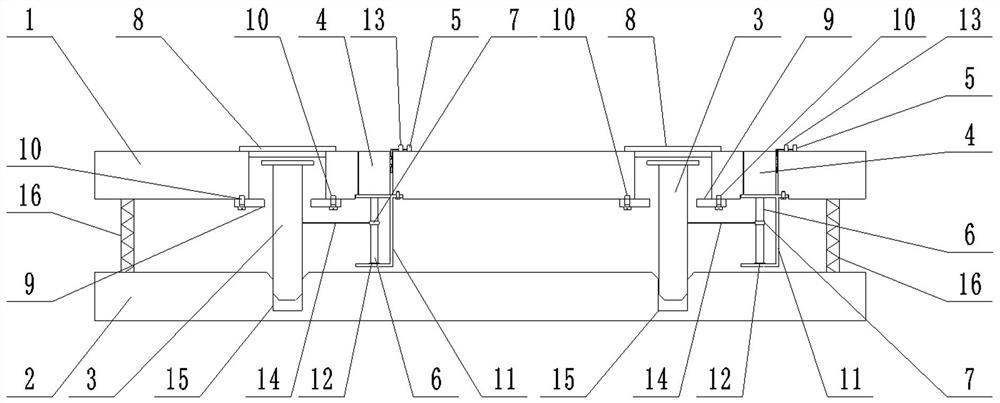

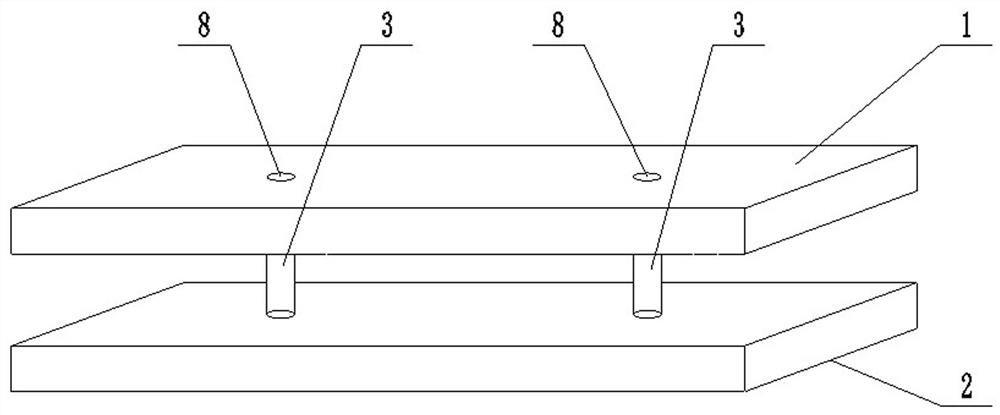

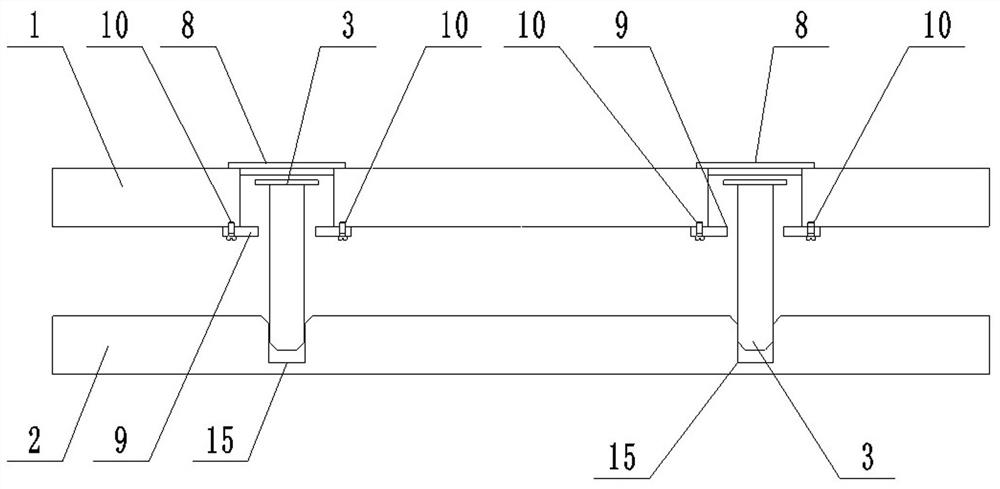

[0025] A keel structure with variable bending stiffness, as attached figure 1 , attached figure 2 , attached image 3 As shown; include the first keel 1 and the second keel 2 which are arranged in parallel and fixedly connected; the upper part of the second keel 2 is worn with two pins 3 which fit with the gap, and the top part of each pin 3 is movable through the first In the through hole of the keel 1 (each pin corresponds to a through hole, and the inner diameter of the through hole is greater than the outer diameter of the pin head), the top of each through hole of the first keel 1 is provided with two upper limit mechanisms that prevent the pin 3 from ejecting, The bottom of the through hole is provided with two lower limit mechanisms to prevent the pins 3 from detaching; the side of each pin 3 is provided with a responsive driving mechanism for driving the pins 3 to move up and down.

[0026] The present invention drives the pin 3 to move up and down through the respo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com