A high-efficiency sand screening device for building construction

A technology for building construction and sand screening, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of low sand screening efficiency and easy clogging of screen holes, and achieve the effect of preventing accumulation and improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

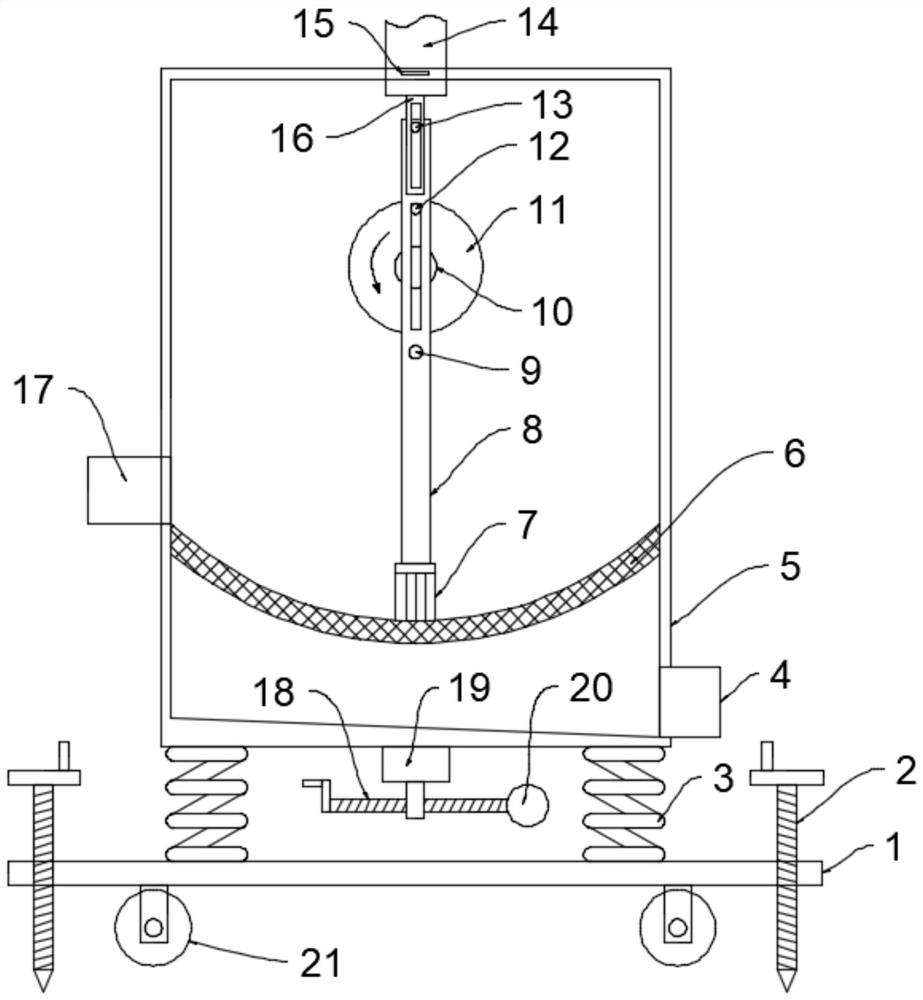

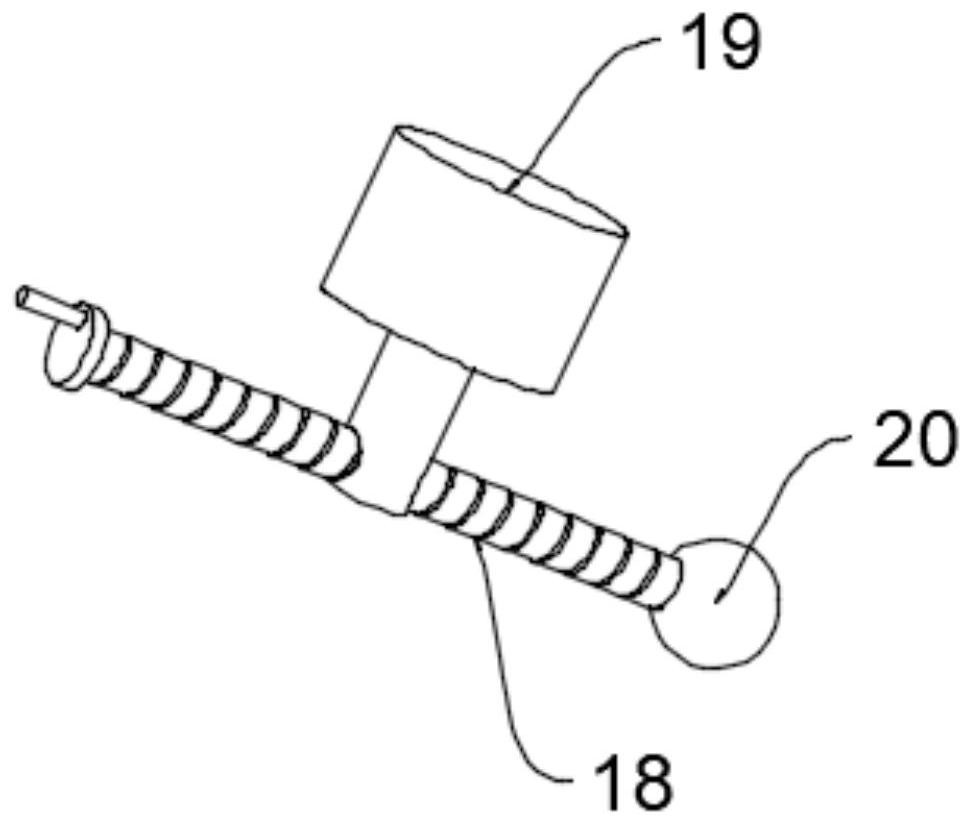

[0023] see Figure 1~2 , in an embodiment of the present invention, a high-efficiency sand screening device for building construction, comprising a sand screening box 5 and a screen 6 fixedly installed in the sand screening box 5, the sand screening box 5 is installed above the bottom plate 1, and the sand screening box 5 The top of the box 5 is connected with a sand inlet pipe 14, and the bottom of one side of the sand screening box 5 is provided with a first discharge port 4, and the bottom of the sand screening box 5 is inclined to the first discharge port 4 to facilitate discharging. 1. Rollers 21 are evenly and symmetrically installed on the bottom. The rollers 21 are self-locking rollers to facilitate the movement of the device. The bottom plate 1 is pierced with a threaded drill rod 2 for fixing the entire device. The threaded drill rod 2 and the bottom plate 1 Threaded connection, the top of threaded drill rod 2 is welded and fixed with a first rocking handle, and a sh...

Embodiment 2

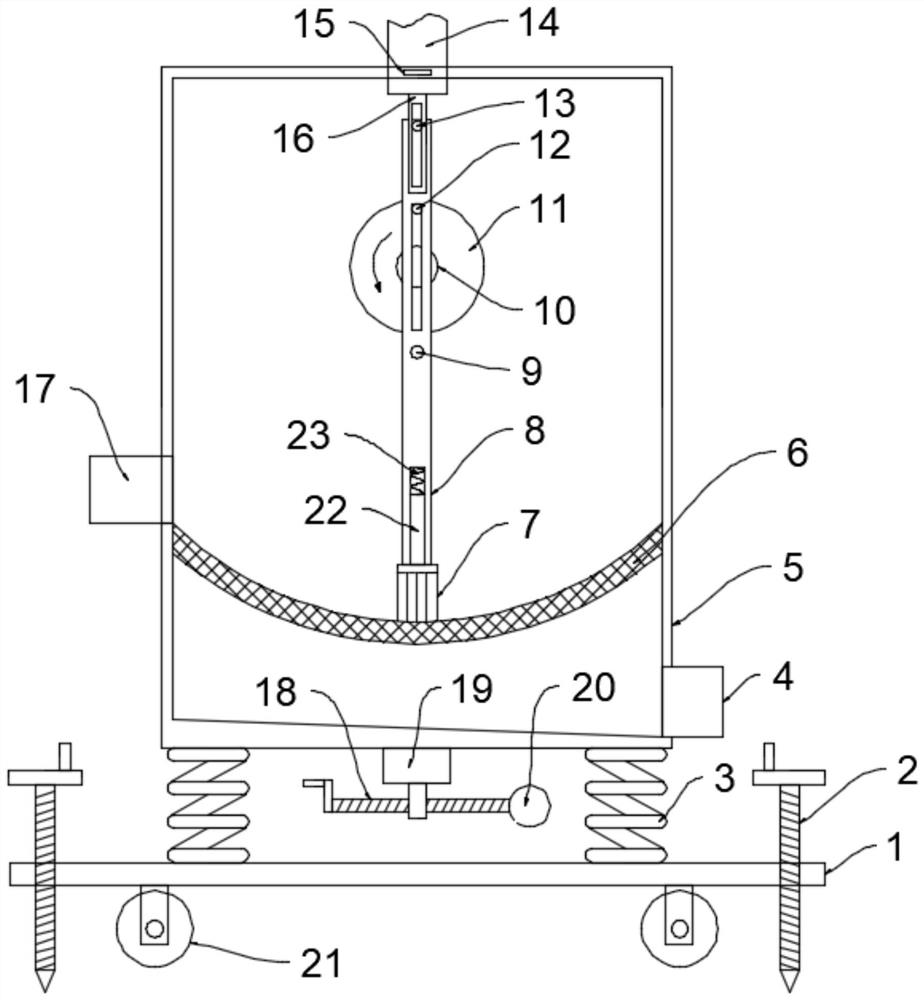

[0026] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that further, in order to reduce the problems caused by the wear of the brush on the brush bar 7, the brush bar 7 is fixed on the bottom end of the installation rod 22, and the installation rod 22 is inserted into the socket provided on the drive rod 8, and a compression spring 23 is connected between the end of the drive rod 8 and the top of the socket, and the elastic force of the compression spring 23 pushes the installation rod 22 and the brush bar 7 to compensate for the wear of the brush .

[0027] The working principle of the present invention is: when working, start the drive motor to drive the drive shaft 10 to rotate, the drive shaft 10 drives the drive disc 11 to rotate, the drive disc 11 drives the drive rod 8 to swing through the first cylindrical pin 12, and the drive rod 8 drives the brush bar 7 swings, and the brush bar 7 constantly brushes the screen cloth 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com