Device for realizing lower spherical hinge of split mounting type swivel support

An assembled, spherical hinge technology, used in bridge parts, bridges, buildings, etc., can solve the problems of damage and collapse of the swivel bearing and the inability to implement the swivel, so as to reduce the risk of crushing and reduce the stress of the main contact surface. , the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

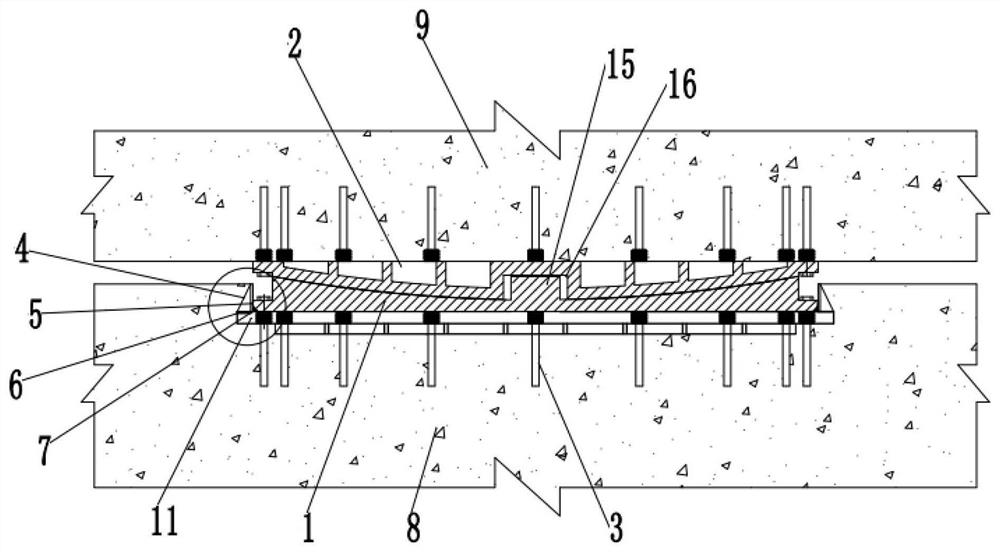

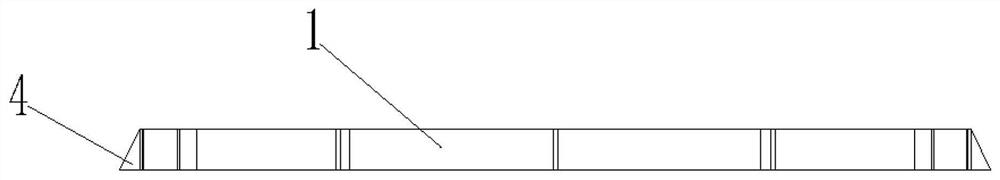

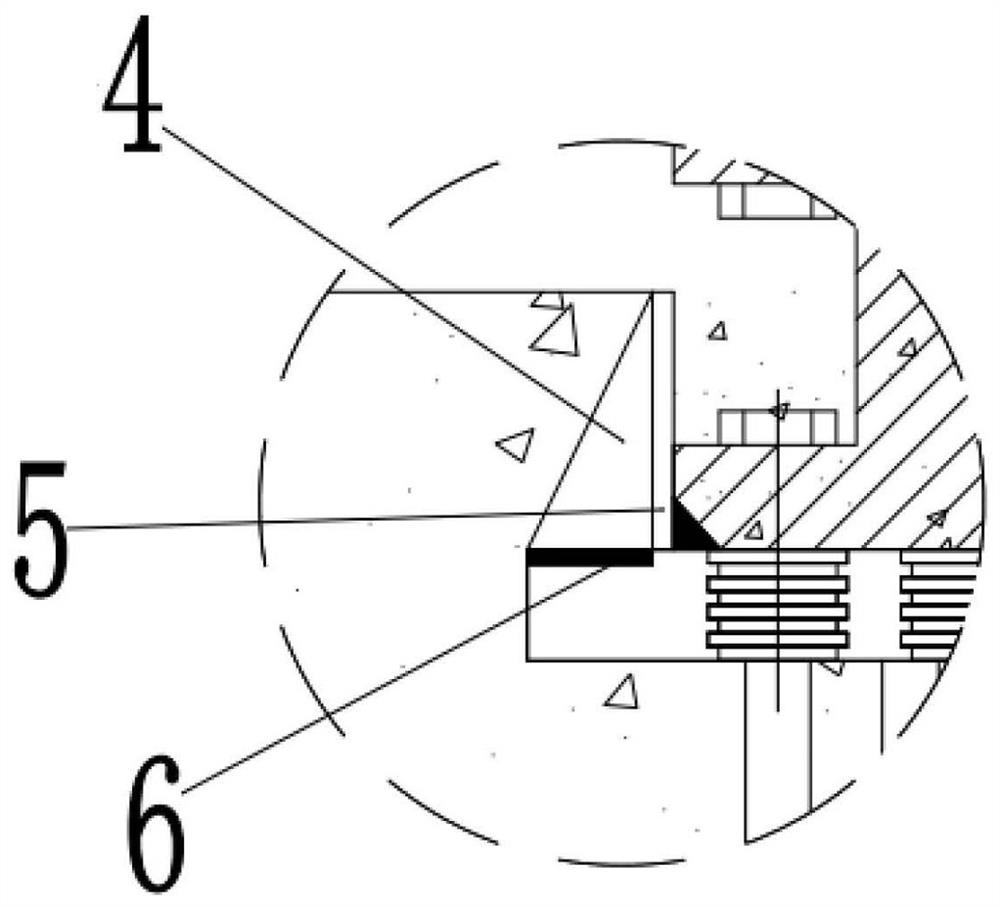

[0033] like Figure 1-10 As shown, a lower spherical hinge device for realizing the assembled swivel support includes a matched lower spherical hinge 1 and an upper spherical hinge 2. The lower spherical hinge 1 includes sub-blocks connected by connectors; it also includes a ring-shaped anti-collapse The structure, the ring-shaped anti-collapse structure includes a ring-shaped reinforcement, which is used to be fixed to the concrete base of the abutment, and the ring-shaped reinforcement is fixedly sleeved on the outer wall of the lower ball hinge 1 .

[0034] The specific embodiment of the present invention provides the lower spherical hinge device for realizing the assembled swivel support, including the matching lower spherical hinge 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com