Anti-toppling iron tower capable of being applied to soft soil

An anti-dumping and iron tower technology, applied in the field of iron towers, can solve problems such as iron tower toppling, achieve uniform force, high connection strength, and improve the effect of soil fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

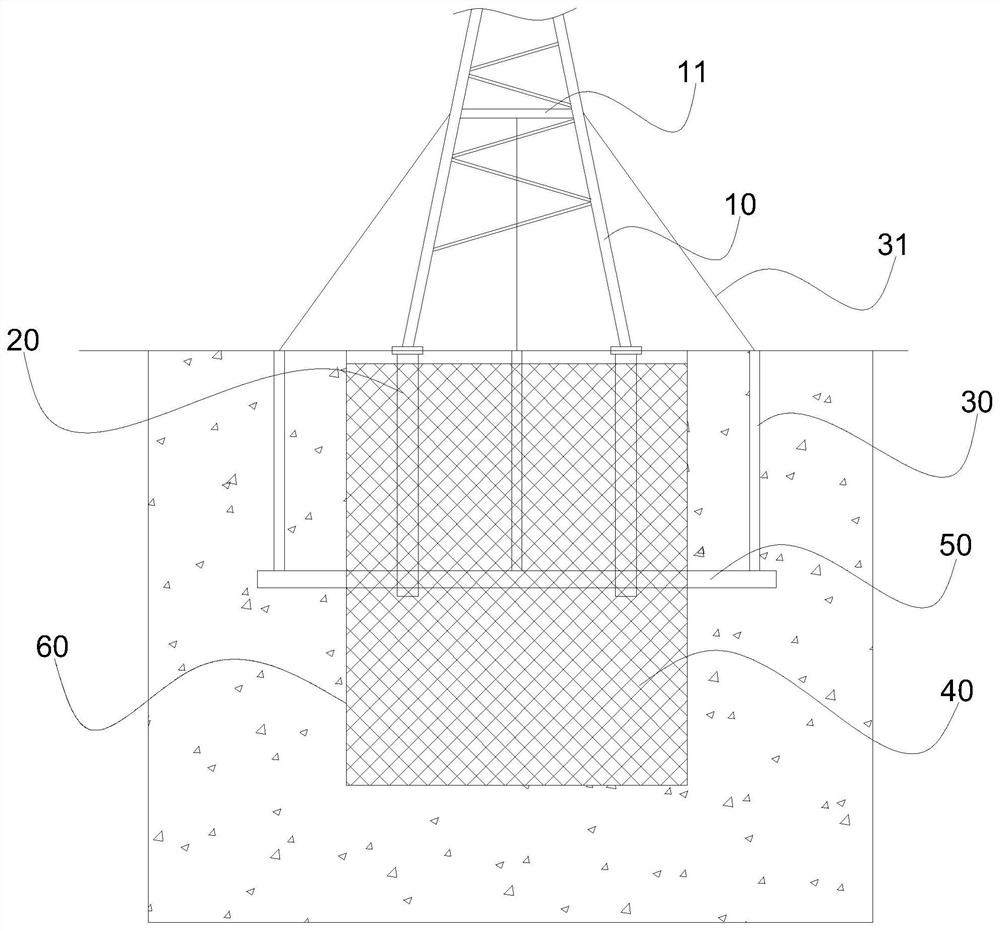

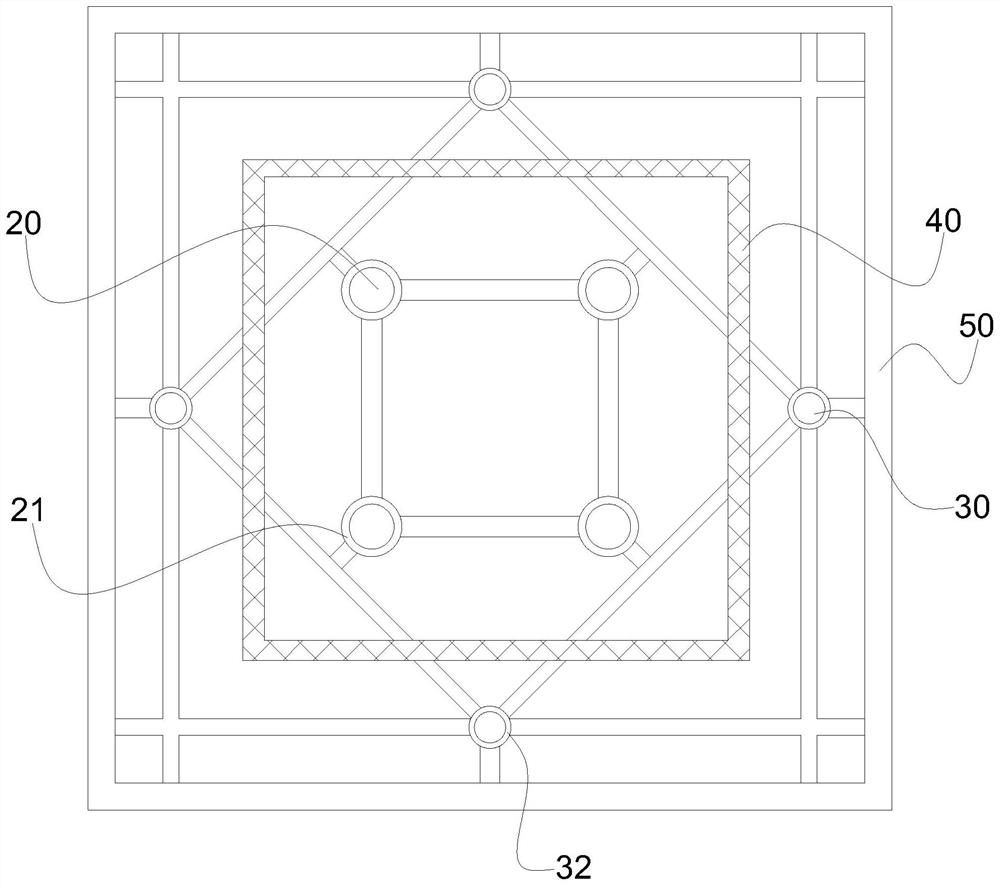

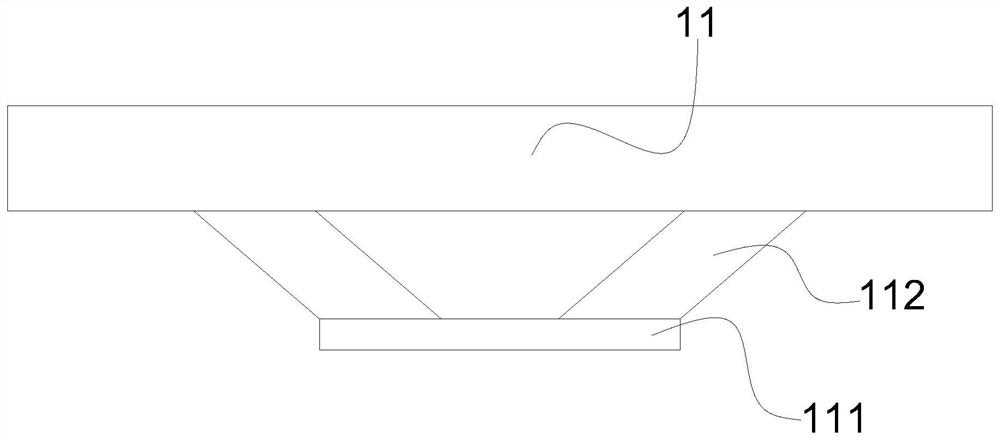

[0037] An anti-dumping iron tower that can be applied to soft soil, such as figure 1 As shown, including the main material 10 that constitutes the main body of the iron tower, a foundation pit 60 is provided below the main body of the iron tower, a mesh cage 40 is arranged in the foundation pit 60, a main column 20 is arranged in the mesh cage 40, and the top of the main column 20 and the main material The bottom of 10 is connected, and the middle part of mesh cage 40 is provided with connection disc 50, and the edge of connection disc 50 extends out of mesh cage 40 and is positioned in soil;

[0038] The bottom of the main column 20 is fixedly connected with the connecting plate 50;

[0039] The cage 40 is filled with concrete.

[0040] In this embodiment, the number of main materials 10 is four.

[0041] The working principle of the present invention is as follows: the mesh cage 40 and the main column 20 itself can be used as a first-level reinforcement for the stability o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com