Packaging quality detection equipment for product design

A technology for testing equipment and product design, applied in computing, measuring devices, data processing applications, etc., can solve problems such as damage to internal items, uneven center of gravity, uneven gravity distribution, etc., to avoid damage, stabilize the center of gravity, and facilitate Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

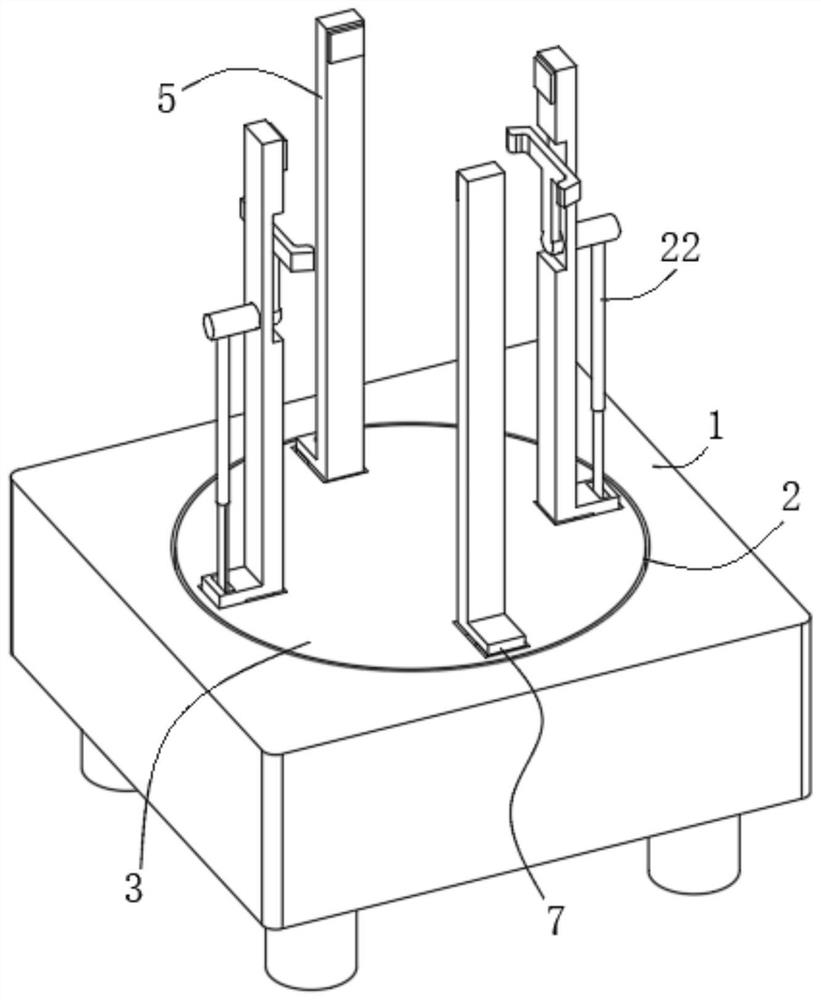

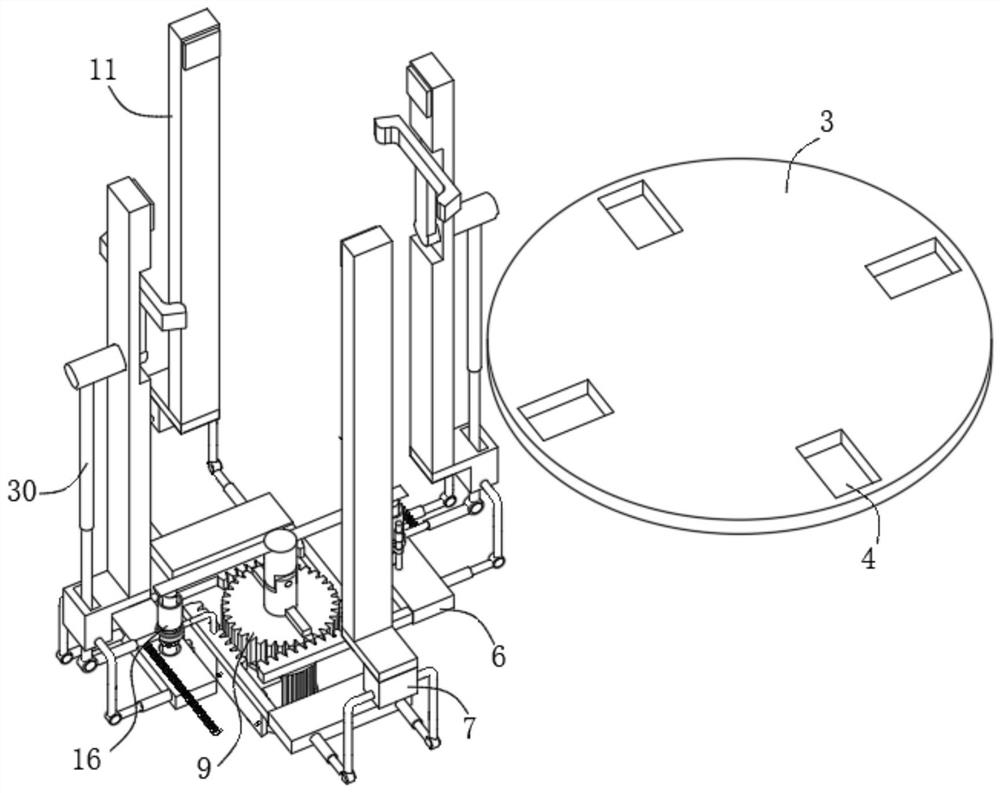

[0026] see Figure 1-Figure 3 , a packaging quality testing equipment for product design in the illustration, including a testing platform 1, a first movable groove 2 is opened on the top surface of the testing platform 1, and a supporting plate 3 is arranged in the first movable groove 2, and the supporting plate 3 is in the shape of The symmetrical structure is provided with a plurality of second movable grooves 4; it also includes a pressure measuring assembly 5, which is used to measure the pressure on each side of the packaging box, and the pressure measuring assembly 5 is arranged in the second movable groove 4; a shaking assembly 16 is used to measure The shaking assembly 16 for packaging stability is arranged under the pallet 3 ;

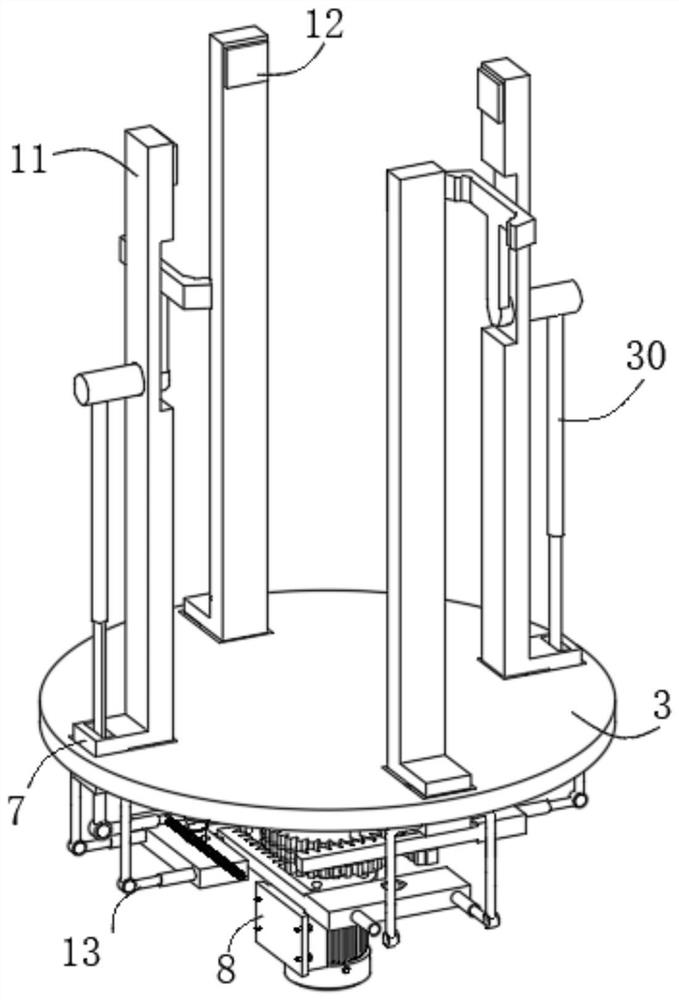

[0027] see Figure 3-Figure 5 , the pressure measurement assembly 5 in the illustration includes a movable block 6 and a motor 8 connected and fixed to the measuring platform. The output shaft of the motor 8 penetrates the first movable gro...

Embodiment 2

[0032] see Figure 1-Figure 3 , a packaging quality testing equipment for product design in the illustration, including a testing platform 1, a first movable groove 2 is opened on the top surface of the testing platform 1, and a supporting plate 3 is arranged in the first movable groove 2, and the supporting plate 3 is in the shape of The symmetrical structure is provided with a plurality of second movable grooves 4; it also includes a pressure measuring assembly 5, which is used to measure the pressure on each side of the packaging box, and the pressure measuring assembly 5 is arranged in the second movable groove 4; a shaking assembly 16 is used to measure The shaking assembly 16 for packaging stability is arranged under the pallet 3 ;

[0033] see Figure 3-Figure 5 , the pressure measurement assembly 5 in the illustration includes a movable block 6 and a motor 8 connected and fixed to the measuring platform. The output shaft of the motor 8 penetrates the first movable gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com