Equipment reliability evaluation and maintenance method

A reliability and equipment technology, applied in the field of equipment reliability evaluation and maintenance, can solve the problems of excessive equipment maintenance, maintenance cycle without considering equipment operation status, insufficient equipment maintenance, etc., to avoid excessive maintenance, reduce blindness, and avoid maintenance. insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1, taking a single switch machine as an example, the reliability evaluation and maintenance method for a single switch machine includes the following steps:

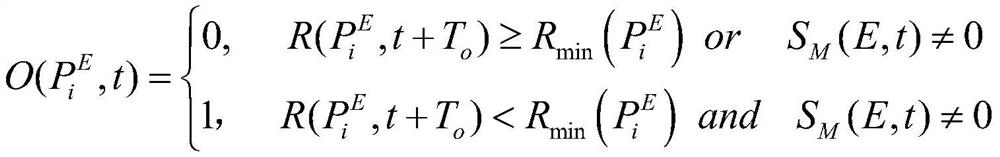

[0067] 1. According to the characteristics of each component of the switch machine, determine the replacement cycle RC and the minimum reliability tolerance R min , the opportunity maintenance time threshold T O ;

[0068] 2. Online monitoring of various electrical signals of the switch machine, and storing the monitoring values to the data server;

[0069] 3. Compare the monitoring data with the normal range value, and generate corresponding alarm and early warning information for the abnormal state;

[0070] 4. Make statistics on the failure time of each component of the switch machine (in days), and use the least square method of Weibull parameter estimation to solve Then the fault distribution model of the switch machine components is obtained

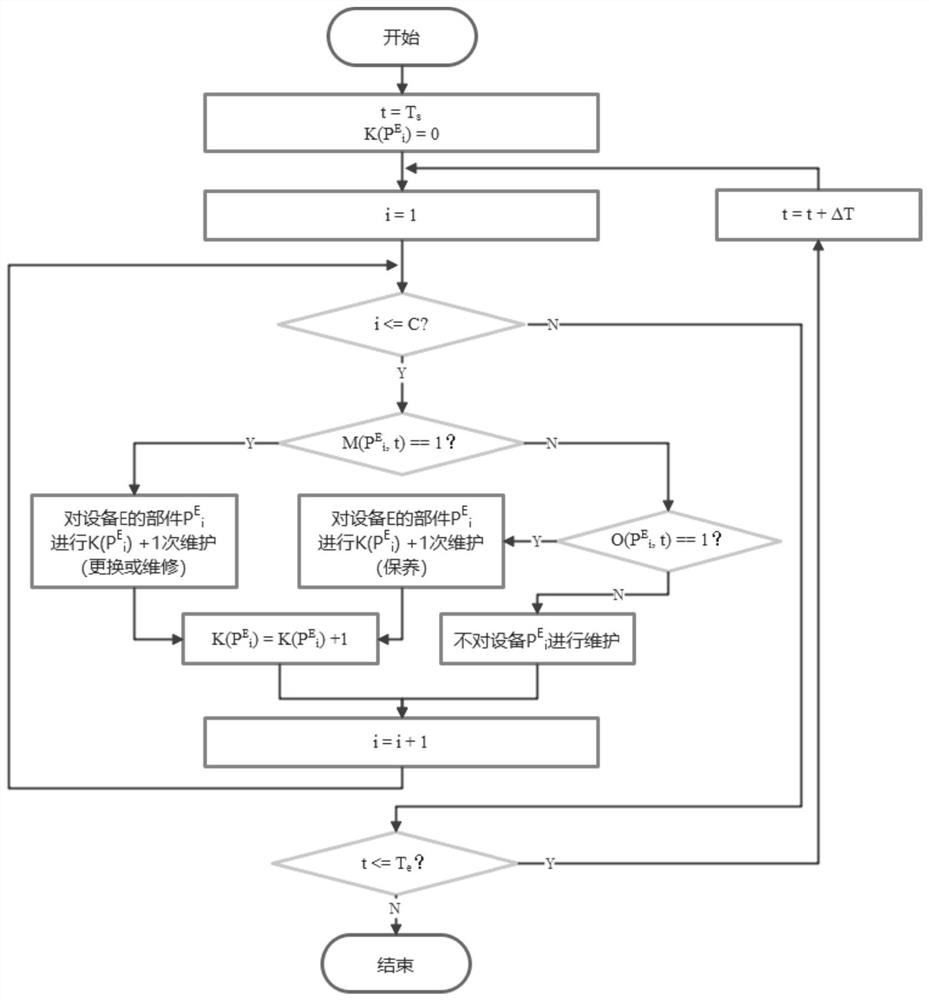

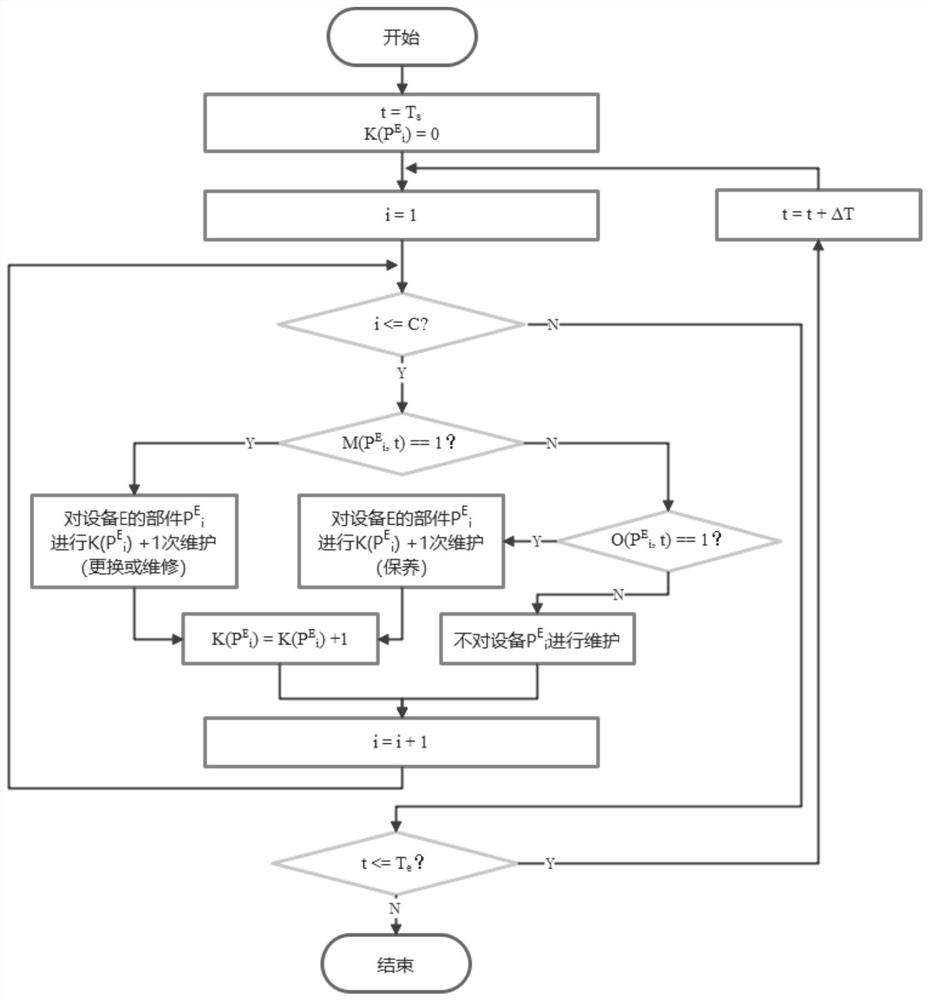

[0071] 5. Carry out as figure 1 In the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com