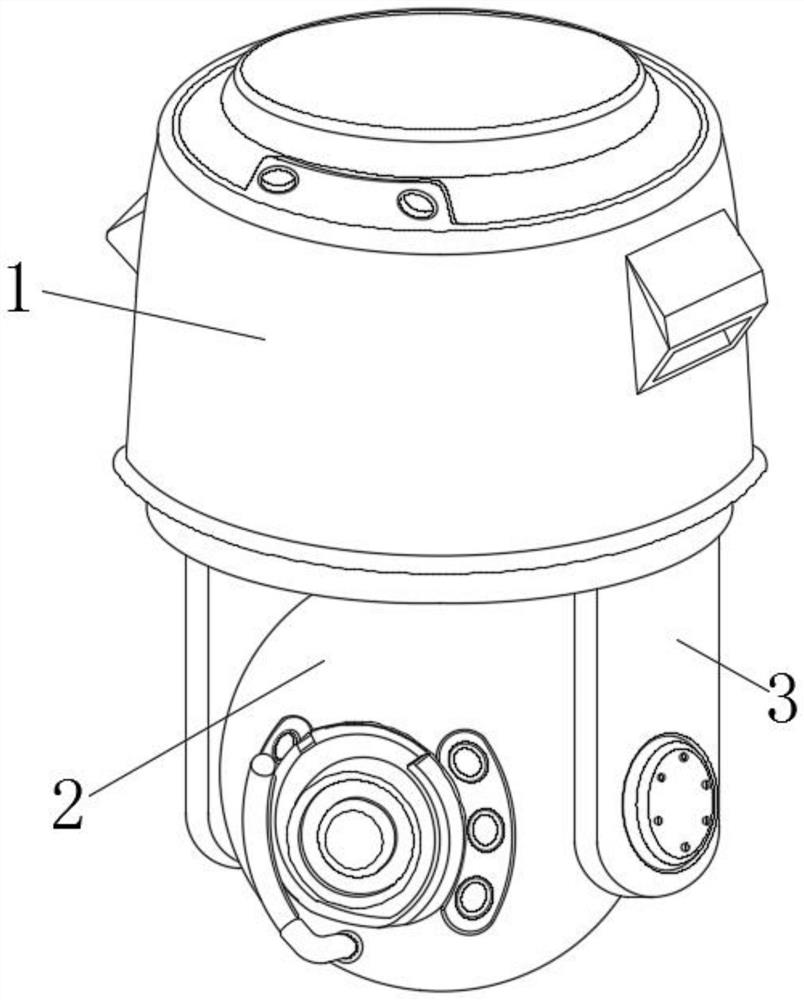

Starlight-level high-definition network spherical intelligent camera

A smart camera, starlight-level technology, applied in the field of cameras, can solve the problems of increased installation limitations and inconveniences, inconsistent camera heights, and difficult temperature drainage, etc., to increase stability and temperature control efficiency, increase adjustability and Flexibility, improved torque and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

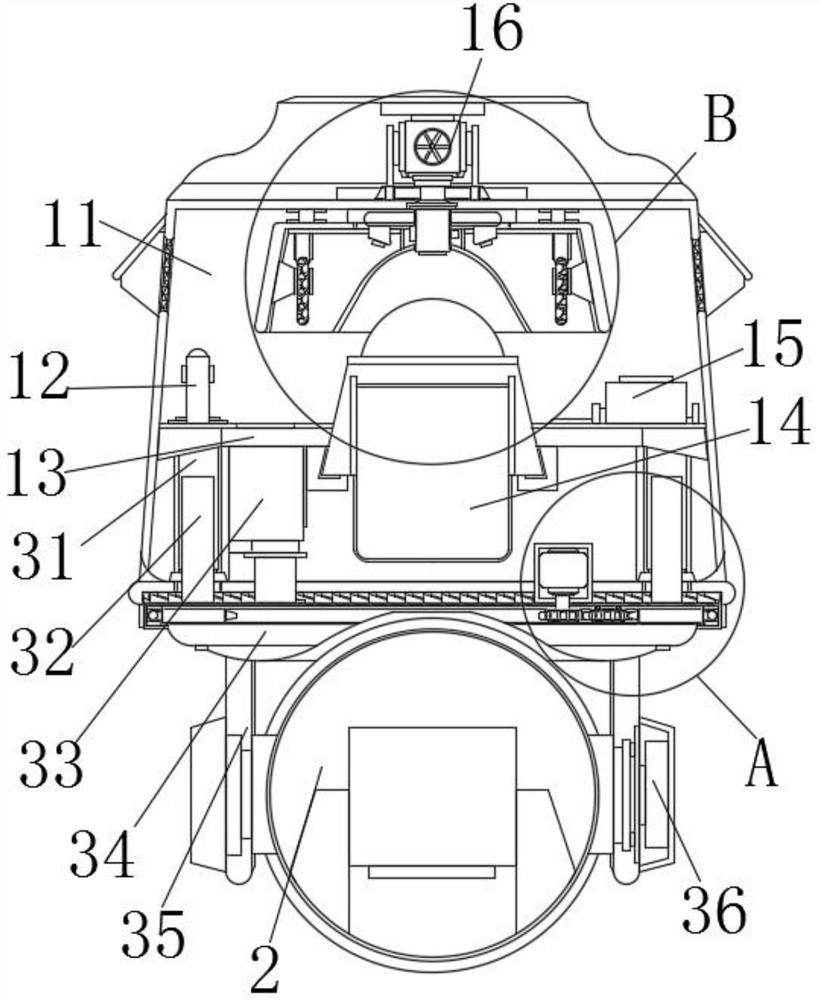

[0038] Example 1, as Figure 1-3 As shown, when the intelligent temperature control system 16 performs heat dissipation work, the annular groove 37 and the annular groove 310 can be separated by the activation of the miniature electric push rod 33, so as to promote the circulation under the installation shell 11, and the miniature blower can be used at this time. The radiating airflow blown by the 161 quickly discharges the heat to the outside, which greatly improves the work efficiency of the cooling of the camera components, and increases the coordination and controllability of the device structure.

Example Embodiment

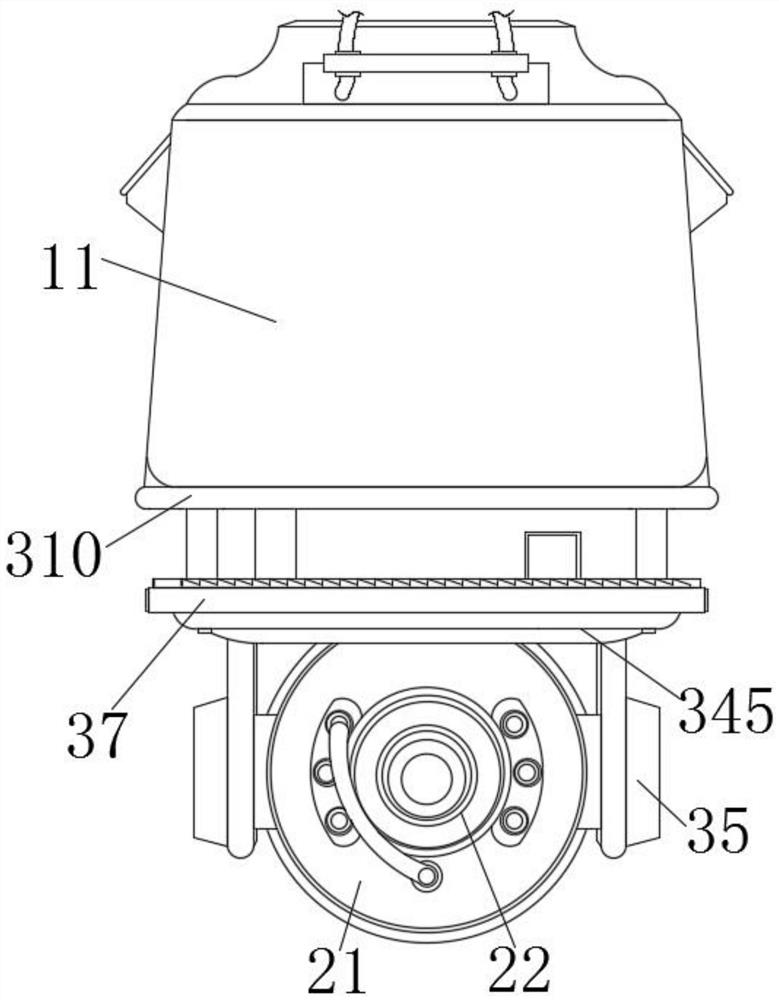

[0039] Example 2, as Figure 5 As shown, when the annular groove 37 and the annular groove 310 are engaged and spliced with each other, the first helical gear ring 38 and the second helical gear ring 39 can be engaged and fixed to effectively improve the sealing performance of the annular groove 37 and the annular groove 310 At the same time, the first helical gear ring 38 and the second helical gear ring 39 are used to hide and seal inside the annular groove 310 to further improve the fit and sealing effect of the annular groove 37 and the annular groove 310, so as to prevent the penetration of cold flow from the outside. Inside the device, increase the protection of the device.

[0040] Working principle: When the device is in use, first place the camera in the designated position. When the height is inconsistent, the annular groove 37 can be driven down by the telescopic guide of the two sets of inner sleeves 32 and outer sleeves 31 through the activation of the miniature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com