Large hollow porous quartz glass preform and manufacturing the same

A technology of quartz glass and manufacturing method, which is applied in the direction of glass manufacturing equipment, glass fiber products, manufacturing tools, etc., to achieve the effect of uniform chlorine concentration or OH group concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

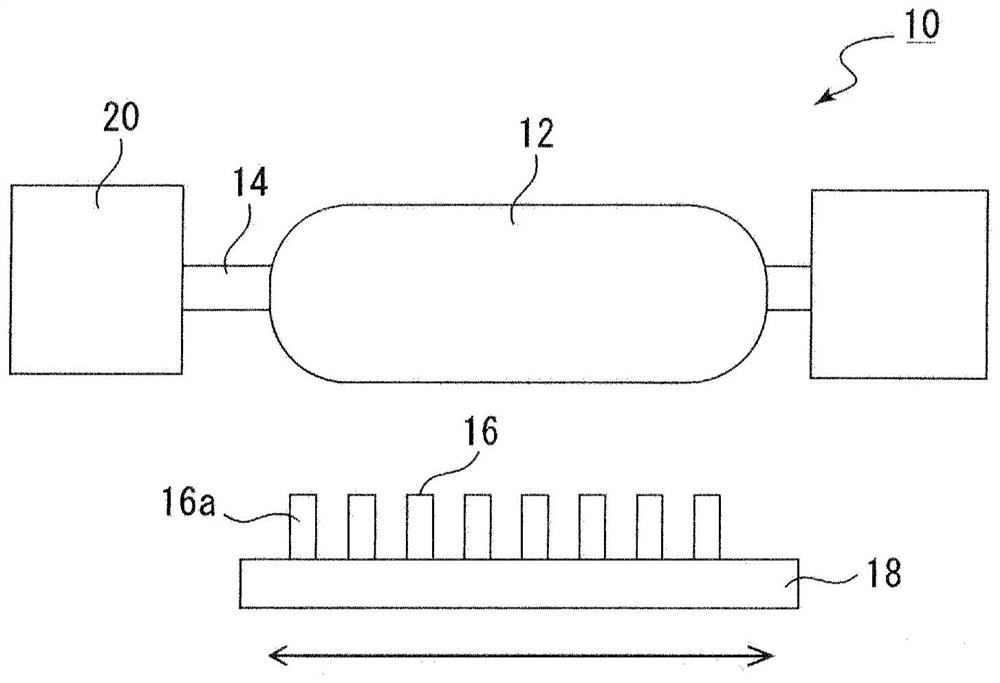

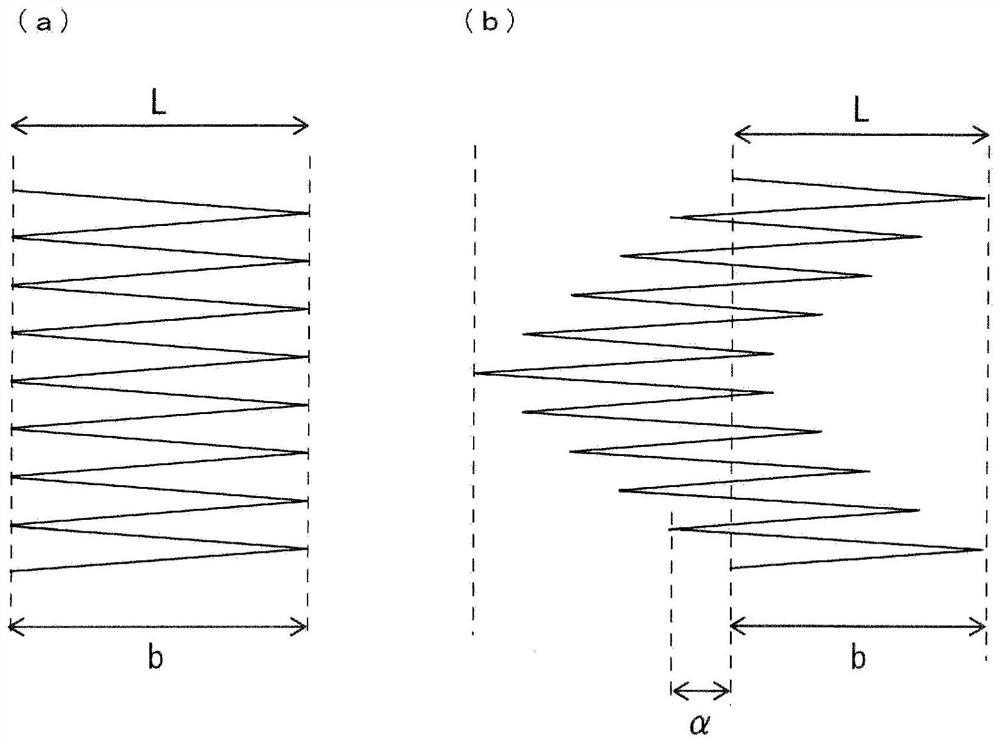

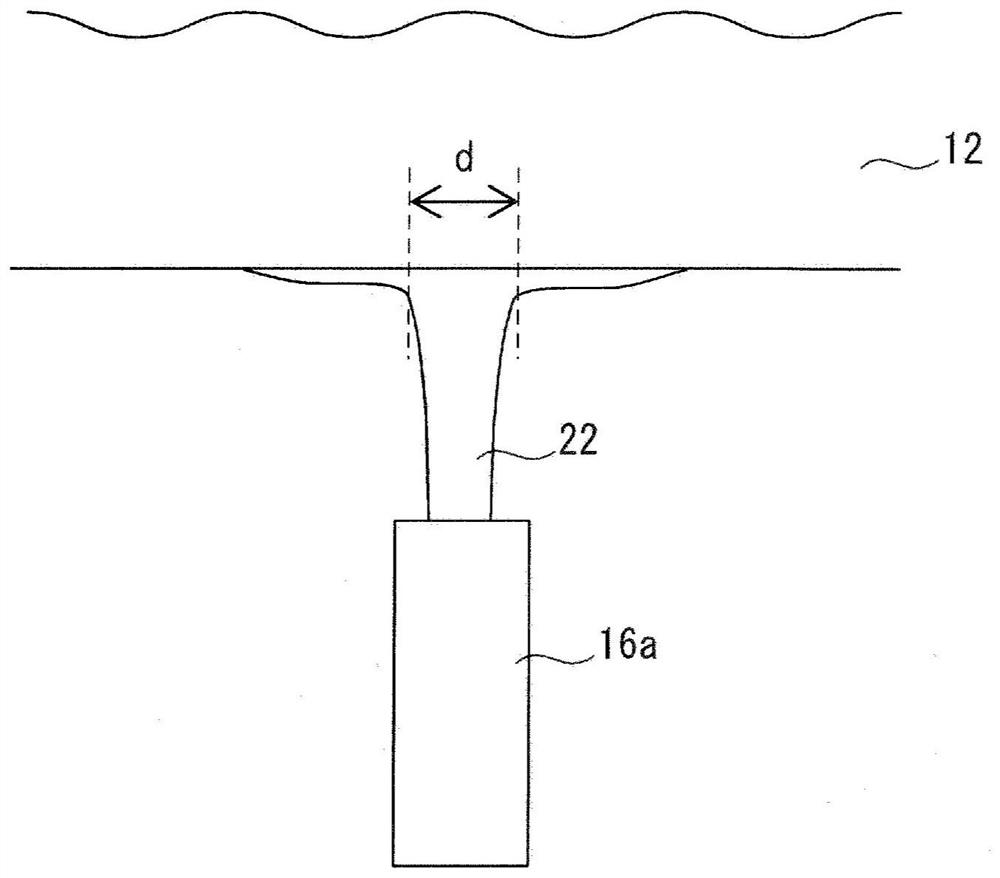

[0110] A plurality of burners for glass particle synthesis are arranged at fixed intervals, and the array of burners is reciprocated (swinged) relative to a rotating target [a ceramic tube with an outer diameter (OD) of 50mm], and glass particles are deposited in layers on the target. Manufacture of glass particle deposits, in the so-called OVD method, under the conditions of burner interval of 100mm, swing distance L of 100mm, swing speed S of 140mm / min (fixed), surface peripheral speed of 11m / min (fixed) A soot body from which a target is pulled out to obtain a hollow porous quartz glass base material. Table 3 shows the production conditions, Table 4 shows the results of the obtained hollow porous silica glass base material, and Tables 5 and 6 show the measurement results of the synthetic silica glass cylinders.

[0111] [table 3]

[0112] manufacturing conditions

[0113]

[0114] When growing the soot body from the target OD of 50 mm to an outer diameter (OD) of 400 m...

Embodiment 2

[0134] A hollow porous silica glass base material was obtained in the same manner as in Example 1 except that the production conditions were changed as shown in Table 3. That is, a soot body was produced under the conditions that the burner interval was 100 mm, the swing distance L was 100 mm, the swing speed S was 200 mm / min (fixed), and the surface peripheral speed was 9 m / min (fixed), and the soot body was pulled out. target to obtain a hollow porous quartz glass base material. Table 4 shows the results of the obtained hollow porous silica glass base materials, and Tables 5 and 6 show the measurement results of the synthetic silica glass cylinders.

[0135] When growing from the target OD50mm to the soot body OD400mm, the rotational speed was reduced from 57.3 rpm to 7.2 rpm under the above conditions. The lowest speed N at this time m 7.2rpm, γ=0.28.

[0136] As a result, it was possible to grow without vibration during the growth of the device, and without cracks towar...

Embodiment 3

[0145] A hollow porous silica glass base material was obtained in the same manner as in Example 1 except that the production conditions were changed as shown in Table 3. That is, a soot body was produced under the conditions of a burner interval of 100 mm, a swing distance L of 100 mm, a swing speed S of 600 mm / min (fixed), and a surface peripheral speed of 9 m / min (fixed), and the soot body was pulled out from the soot body. target to obtain a hollow porous quartz glass base material. Table 4 shows the results of the obtained hollow porous silica glass preforms, and Table 5 shows the measurement results of the synthetic silica glass cylinders.

[0146] In the case of growing from the target OD50mm to the soot body OD400mm, the rotational speed was reduced from 57.3 rpm to 7.2 rpm under the above conditions. The lowest speed N at this time m 7.2rpm, γ=0.84.

[0147] As a result, it was possible to grow without vibration during the growth of the device, and without cracks to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com