Elevator door bearing strength detector

A technology for compressive strength and elevator doors, applied in the direction of strength characteristics, the use of stable tension/pressure testing material strength, instruments, etc., can solve the problems of elevator door performance impact, large damage, low test efficiency, etc., to achieve improvement The effect of intensity work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

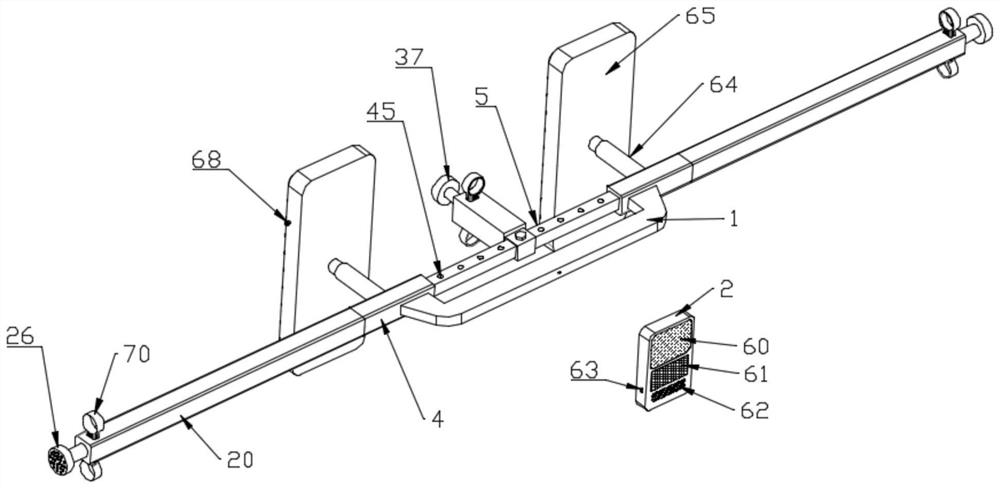

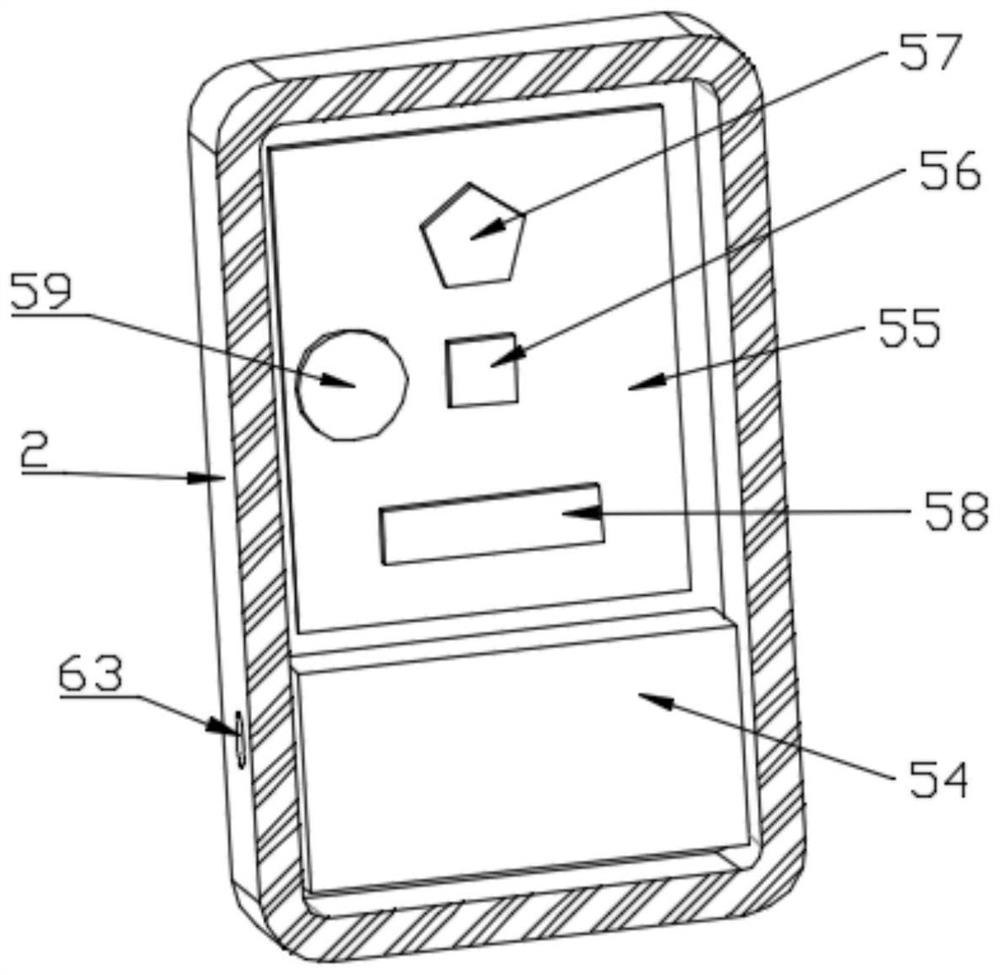

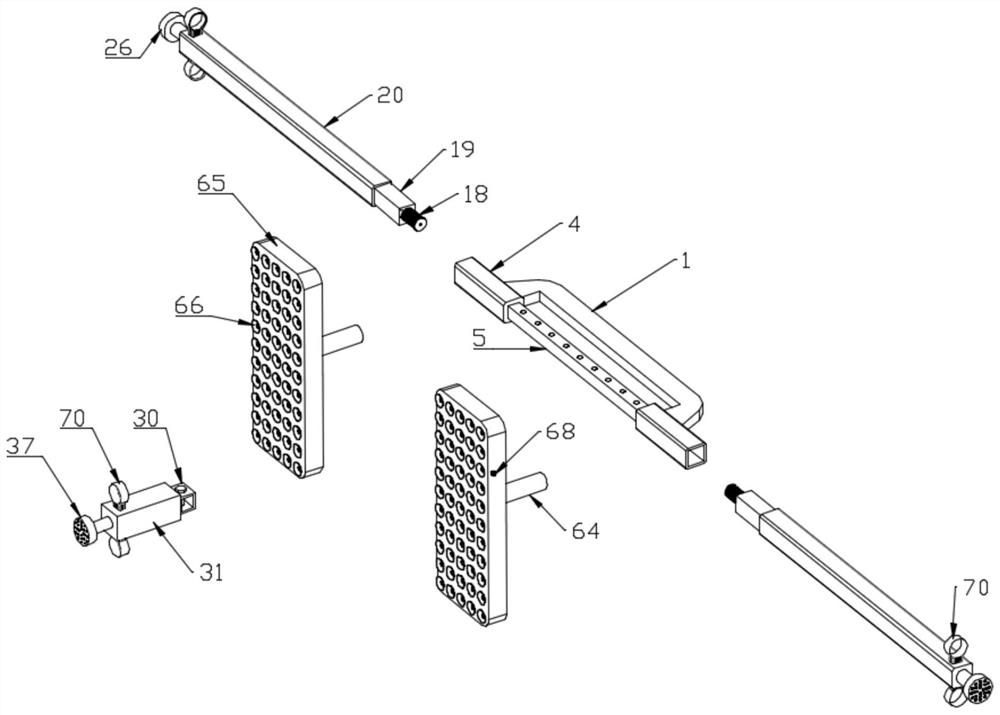

[0044] Such as Figure 1-15 , The present invention provides a tester for the bearing strength of an elevator door, comprising a handheld frame 1, a controller 2, a detection component and a repair component.

[0045] The handheld frame 1 is U-shaped, and the cavity 3 inside the handheld frame 1 is provided with a control assembly. The ends of the handheld frame 1 are provided with connecting arms 4 perpendicular to the opening direction thereof, and the central axes of the two connecting arms 4 are collinear. A guide rod 5 is arranged between the connecting arms 4 . In this embodiment, the handheld frame 1, the connecting arm 4 and the guide rod 5 are made by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com