Dismounting and mounting device and method for brake disc for locomotive

A technology for installing devices and brake discs, which is applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of cumbersome installation, hidden dangers of installation, and hidden safety hazards, and achieve safe and firm operation, simple use method, The effect of no safety hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

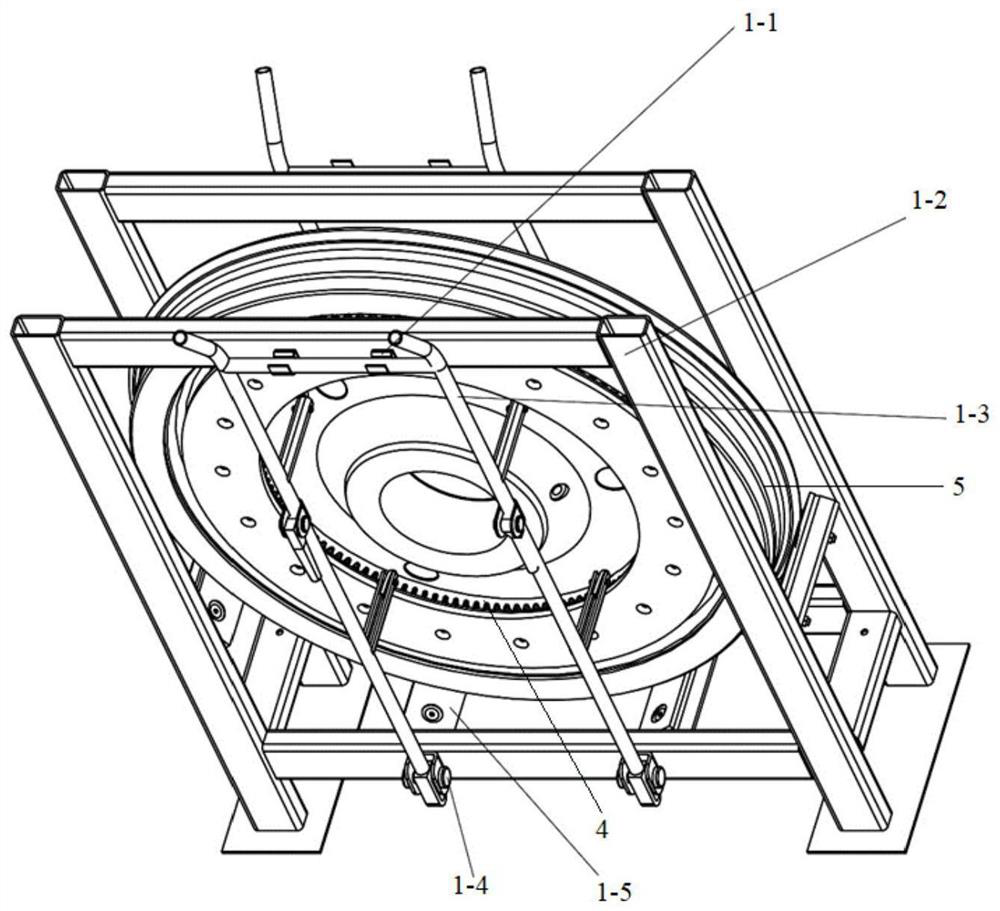

[0045] The following will be combined with Figure 1-4 The technical solution of a brake disc removal and installation device for a locomotive according to the present invention is described in detail with specific embodiments.

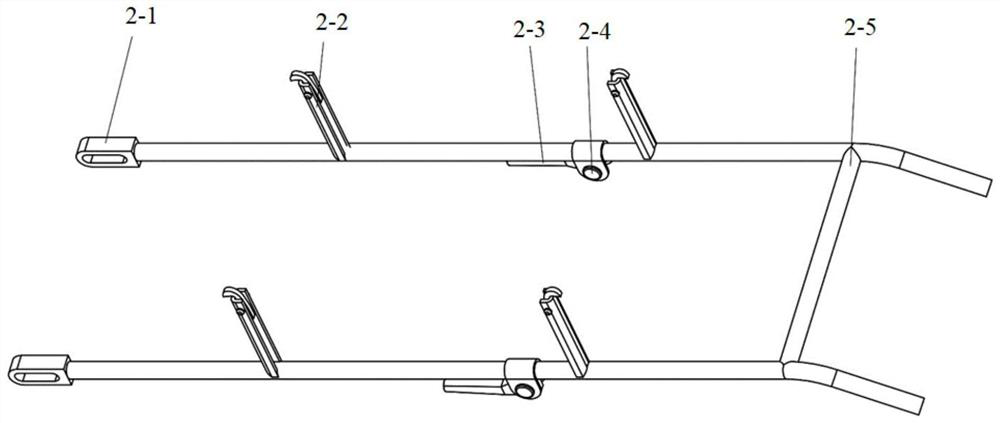

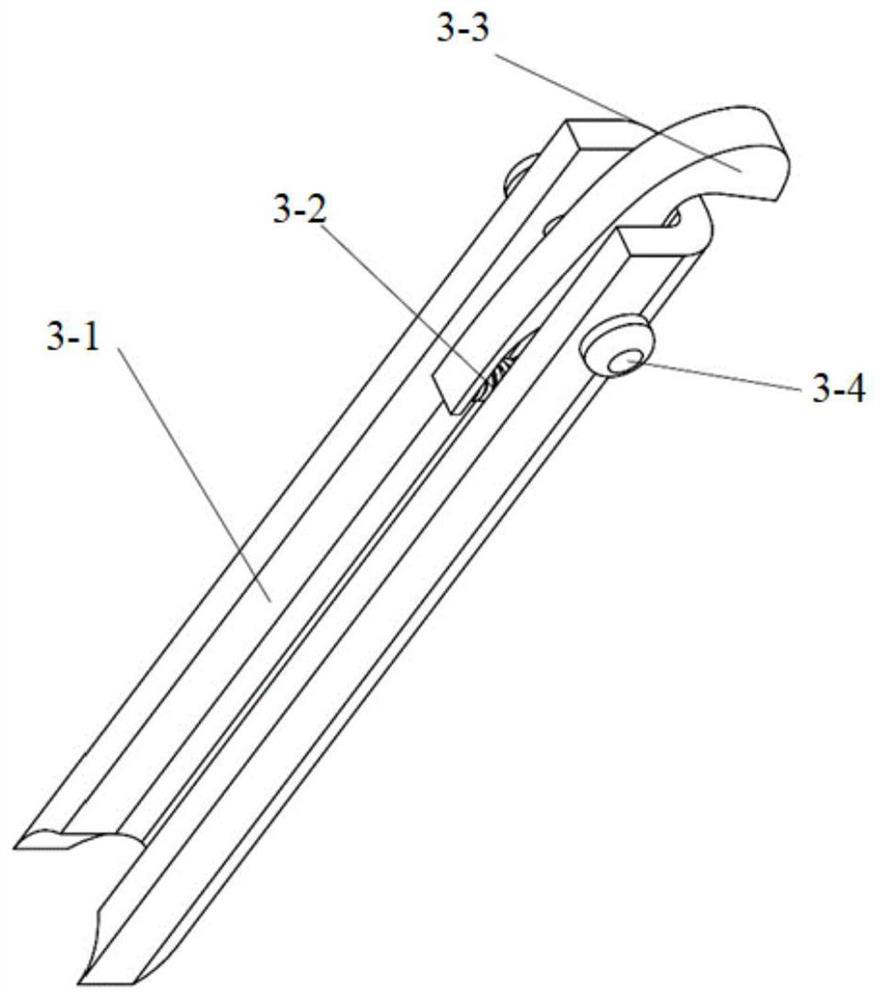

[0046] Such as Figure 1-4 As shown, a brake disc dismounting and installing device for a locomotive in this embodiment, the whole device adopts a device integrating disassembly, installation and transportation, including wheel cake storage rack 1-2, brake disc support frame 1-3, Rotary shaft one 1-4, brake disc support frame hook 1-1. The cake storage rack 1-2 includes two frames, the two frames are arranged opposite to each other and placed vertically, and the bottoms are connected to each other to form an accommodating space that is open above and supports the cakes at the bottom. A brake disc support frame 1-3 is correspondingly connected to the outside of each side frame, and each side brake disc support frame 1-3 includes a skeleton 2-5, a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com