Forming die and forming process of automobile decoration ring

A technology for forming molds and molding processes, which is applied to household appliances, other household appliances, household components, etc., and can solve problems such as loose mold fit and wear of positioning holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

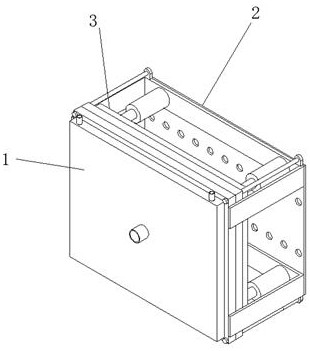

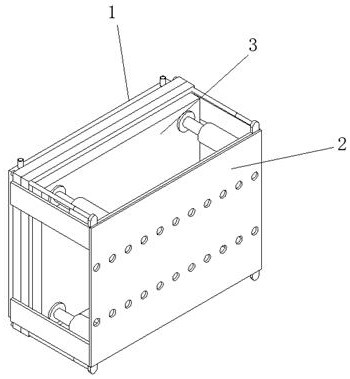

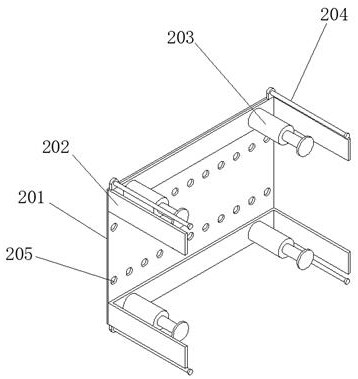

[0036] In the production process of the automobile decoration ring, the present invention provides a molding die and its molding process for the automobile decoration ring. During the working process, it is necessary to rely on the rubber injection molding machine for the injection molding operation. During the injection molding process, the cooling water needs to be continuously circulated to cool the mold. The cooling water needs a special cooling tower for the circulating cooling operation. The two ends of the cooling water are respectively Connected to the water inlet pipe 105 and the water outlet pipe 106 of the cooling plate 101 of the present invention, the temperature of the cooling water flow after the water inlet pipe 105 is input into the cooling is low, and the equipment needs to be raised by using a fixing frame and other equipment to place the equipment at a suitable height for injection molding operation. .

[0037] Such as Figure 1-6 As shown, the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com