Coiled material cutting device with fixed distance for leather product production

A coil cutting and spacing technology, applied in leather punching/punching/cutting, application, raw hide/leather/fur manufacturing equipment, etc., can solve the problems of coil cutting position offset, insufficient uniform force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

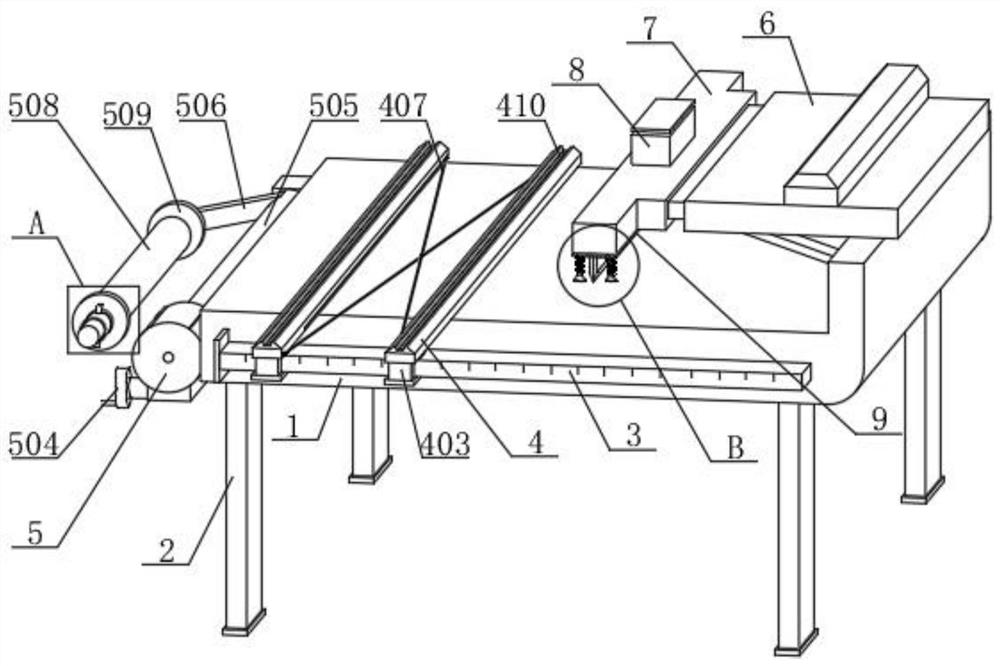

[0037]A fixed-distance coil material cutting device for leather goods production, comprising a workbench 1, a foot 2 is connected to the bottom end of the workbench 1, a measuring ruler 3 is connected to the front end of the workbench 1, and the measuring ruler 3 The top of the workbench 1 is provided with a fixed distance structure 4, and the top side of the workbench 1 is provided with a servo telescopic frame 6, and one side of the servo telescopic frame 6 is connected with a complete machine 7, and the top of the complete machine 7 is connected with a motor 8. The output end of the motor 8 is provided with a cutting structure 9, the cutting structure 9 includes an integrated plate 901, the middle of the bottom end of the integrated plate 901 is connected with a blade 902, and the bottom end of the integrated plate 901 is a Both sides are provided with a buffer column 903, the buffer column 903 runs through the integration plate 901, and the buffer column 903 is slidingly co...

Embodiment 2

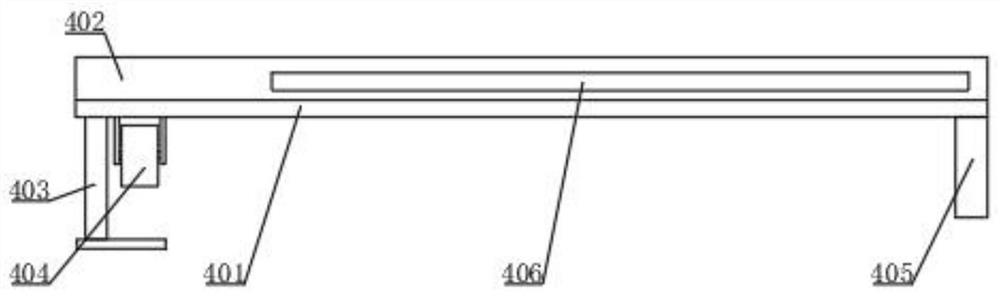

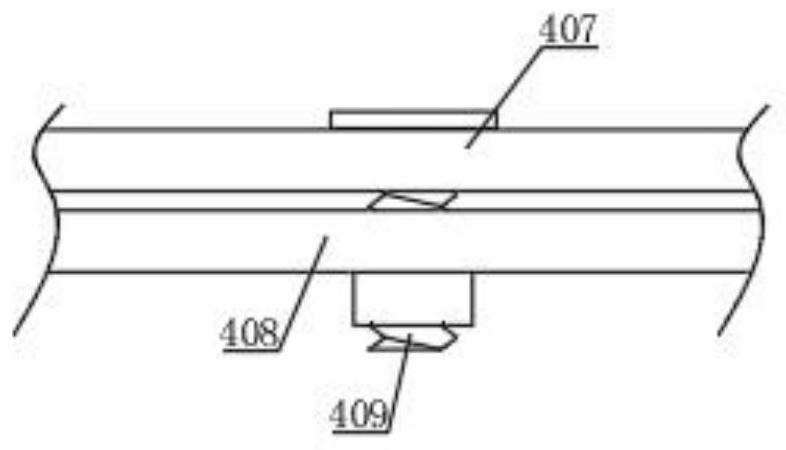

[0039] As a further optimization scheme of the above embodiment: the fixed distance structure 4 includes a bottom plate 401, and the bottom plate 401 is slidingly connected with the workbench 1, the top of the bottom plate 401 is connected with a spacer 402, and the bottom plate 401 on one side The outer side of the first connecting shaft 407 is rotatably connected, and the first connecting shaft 407 is slidably connected with the bottom plate 401 on the other side, and the second connecting shaft 408 is rotated on the outer side of the bottom plate 401 on the other side, and the second The connecting shaft 408 is slidingly connected to the bottom plate 401 on one side, and the middle position of the first connecting shaft 407 is provided with a positioning threaded shaft 409, and the positioning threaded shaft 409 runs through the first connecting shaft 407 and the second connecting shaft 408, and The positioning threaded shaft 409 is rotationally connected with the first conn...

Embodiment 3

[0041] As a further optimization scheme of the above-mentioned embodiment: the bottom end side of the bottom plate 401 is connected with a first splint 403, and the first splint 403 is slidably connected with the measuring ruler 3, and the top of the measuring ruler 3 is slidably connected with a pulley 404, And the pulley 404 is connected with the bottom plate 401, and the other side of the bottom end of the limit frame 402 is connected with a second splint 405, and the second splint 405 is slidably connected with the workbench 1, directly pushing the bottom plate 401 to be positioned by the first splint 403 One side of the ruler 3 is measured, and the second splint 405 is positioned on the outside of the workbench 1 to keep the bottom plate 401 moving smoothly on the workbench 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap