Aircraft test rain simulation device and simulation method

A simulation device and aircraft technology, applied in the field of aircraft test rain simulation device, can solve the problem that the rain test cannot be fully applied, and achieve the effects of preventing falling, reducing reliability and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

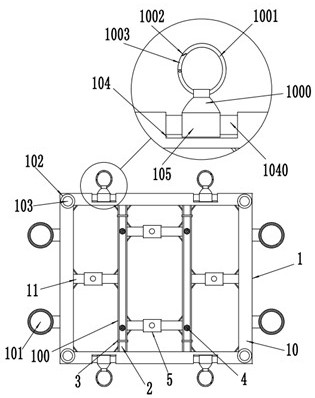

[0053] like image 3 As shown, an aircraft test rain simulation device includes a modular spray rack 1, nine water supply pipelines 2 arranged on the modular sprinkler rack 1, and four pipe clamps 3 for fixing the water supply pipeline 2 , the nozzle 4 provided on the water supply pipeline 2, the balance lifting point 5 for hoisting the modular spray rack 1;

[0054] The modular spray rack 1 is composed of three modular frames 10 that are spliced with each other. Each modular frame 10 is spliced by two criss-crossing aluminum alloy beams 11. The side walls of each modular frame 10 are Two sets of connecting hooks 100 and two sets of connecting rings 101 are respectively arranged in relative distribution, and a storage seat 102 is respectively provided at the four corners of the module frame 10, and the upper end of the storage seat 102 is provided with a snap-in notch 103,

[0055] The side wall of module frame one 10 is provided with a gap 104 corresponding to two groups...

Embodiment 2

[0063] This embodiment is basically the same as Embodiment 1, the difference is:

[0064] like Figure 4 , 5 As shown, the modular spray rack 1 is replaced by a foldable spray rack, and the foldable spray rack includes a module frame two 12, two foldable frames 13 arranged on the left and right sides of the two module frame 12, and the foldable frame 13 is composed of a plurality of splicing sub-boards 130, two adjacent splicing sub-boards 130 are connected by hinges 131, the four corners of the module frame 12 are provided with storage seats 2 120, and the module frame 2 12 is made of a plurality of criss-cross aluminum Beam 2 14 made of alloy material is spliced, each splicing sub-board 130 is provided with beam 3 132, the water supply pipeline 2 is connected with beam 2 14 and beam 3 132 through pipe clamp 3, and the balance lifting point 5 is set on the On beam two 14 and beam three 132;

[0065] Both sides of the module frame two 12 are provided with snap rings 121, an...

Embodiment 3

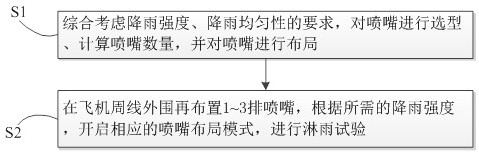

[0070] What present embodiment records is the simulation method of the aircraft test rain simulation device of embodiment 1, comprises the following steps:

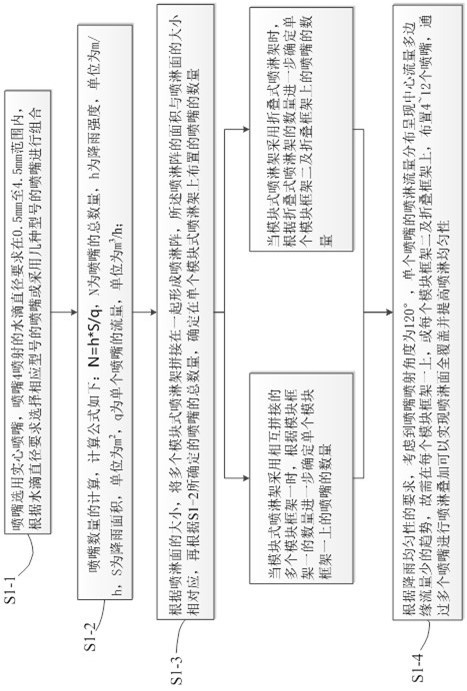

[0071] S1. Comprehensively consider the requirements of rainfall intensity and rainfall uniformity, select nozzles 4, calculate the number of nozzles 4, and arrange the nozzles 4, including:

[0072] S1-1, nozzle 4 selection:

[0073] The nozzle 4 is a solid nozzle, and the diameter of the water droplets sprayed by the nozzle 4 is required to be in the range of 0.5mm to 4.5mm. According to the requirements of the diameter of the water droplets, select the corresponding type of nozzle 4 or use several types of nozzles 4 for combination;

[0074] S1-2, the calculation of the number of nozzles 4, the calculation formula is as follows:

[0075]

[0076] in, is the total number of nozzles 4, is the rainfall intensity in m / h, is the rainfall area, the unit is m 2 , is the flow rate of a single nozzle 4, in m 3 / h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com