Beverage sterilization control method, device and system

A control method and beverage technology, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve problems such as unqualified beverage sterilization temperature, missing monitoring alarm, sluggish fluid process, etc., and achieve the effect of avoiding dietary risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

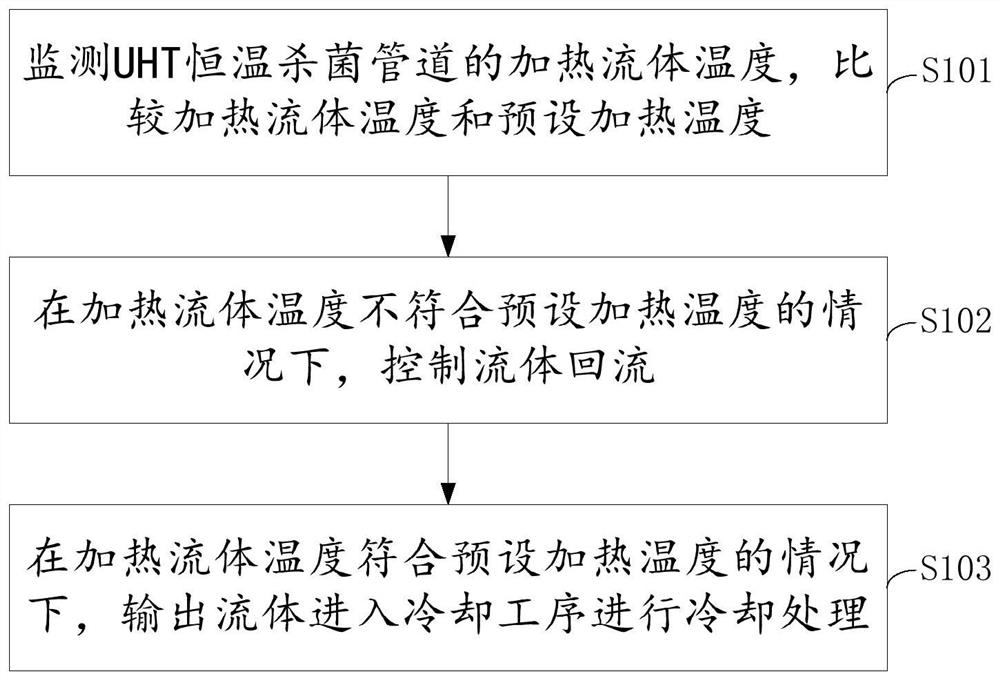

[0058]see figure 1 , this embodiment provides a beverage sterilization control method.

[0059] It should be noted, figure 1 The execution body of the shown methods may be software and / or hardware devices. The subject of execution of the present application may include but not limited to at least one of the following: user equipment, network equipment, and so on. Wherein, the user equipment may include, but not limited to, a computer, a smart phone, a personal digital assistant (Personal Digital Assistant, PDA for short), and the electronic equipment mentioned above. Network devices may include, but are not limited to, a single web server, a server group composed of multiple web servers, or a cloud composed of a large number of computers or web servers based on cloud computing, where cloud computing is a type of distributed computing consisting of a group of loosely coupled A super virtual computer composed of computers. This embodiment does not limit this.

[0060] In th...

Embodiment 2

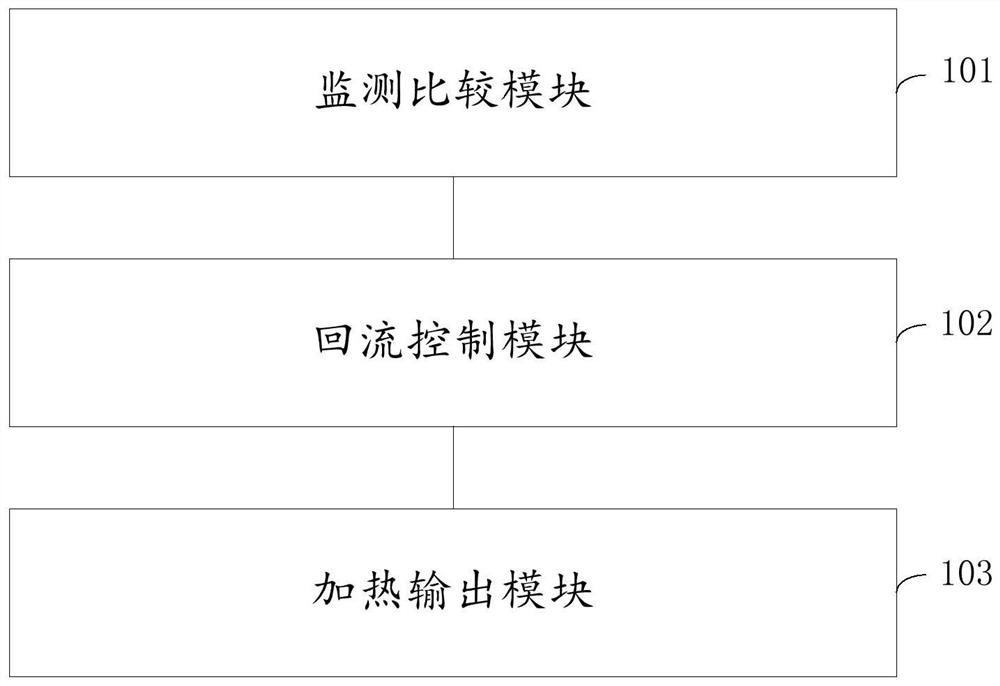

[0071] see figure 2 , corresponding to Embodiment 1, this embodiment provides a beverage sterilization control device, which includes a monitoring and comparison module 101, a reflux control module 102, and a heating output module 103, specifically as follows:

[0072] The monitoring comparison module 101 is used to monitor the temperature of the heating fluid of the UHT constant temperature sterilization pipeline, and compare the temperature of the heating fluid with the preset heating temperature;

[0073] A reflux control module 102, configured to control the reflux of the fluid when the temperature of the heating fluid does not meet the preset heating temperature;

[0074] The heating output module 103 is configured to output the fluid into the cooling process for cooling treatment when the temperature of the heating fluid meets the preset heating temperature.

[0075] It should be noted that the beverage sterilization control device provided in this embodiment is the re...

Embodiment 3

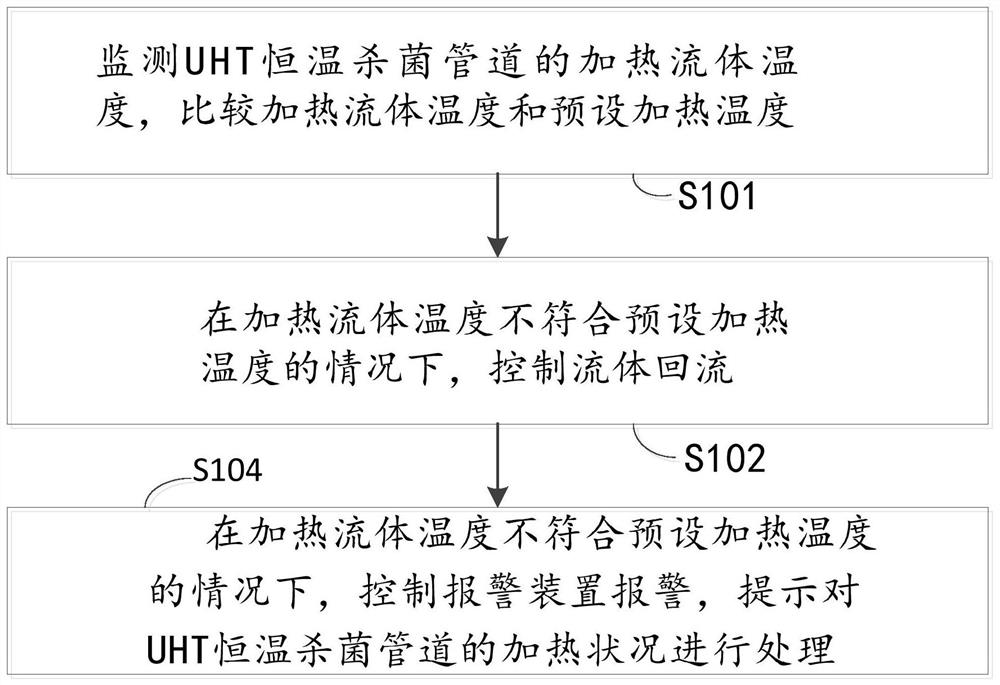

[0077] see image 3 , on the basis of Embodiment 1, this embodiment proposes an improved beverage sterilization control method, the method includes step S104, specifically as follows:

[0078] S104, in the case that the temperature of the heating fluid does not meet the preset heating temperature, control the alarm device to give an alarm, prompting to handle the heating status of the UHT constant temperature sterilization pipeline.

[0079] It should be noted that the technical features of step S104 are more related to the monitoring of the temperature of the heating fluid. When the temperature of the heating fluid does not meet the preset heating temperature, the alarm device is controlled to give an alarm, prompting to process the heating status of the UHT constant temperature sterilization pipeline. , which is beneficial to prompt the operator to adjust the heating status in time in the workshop environment and correct the deviation in time. For example, adjust the concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com