Cleaning equipment for removing impurities in rice

A technology for cleaning equipment and impurities. It is applied in the direction of separating solids from solids by air flow, dispersing particle filtration, solids separation, etc., and can solve problems such as dust and metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

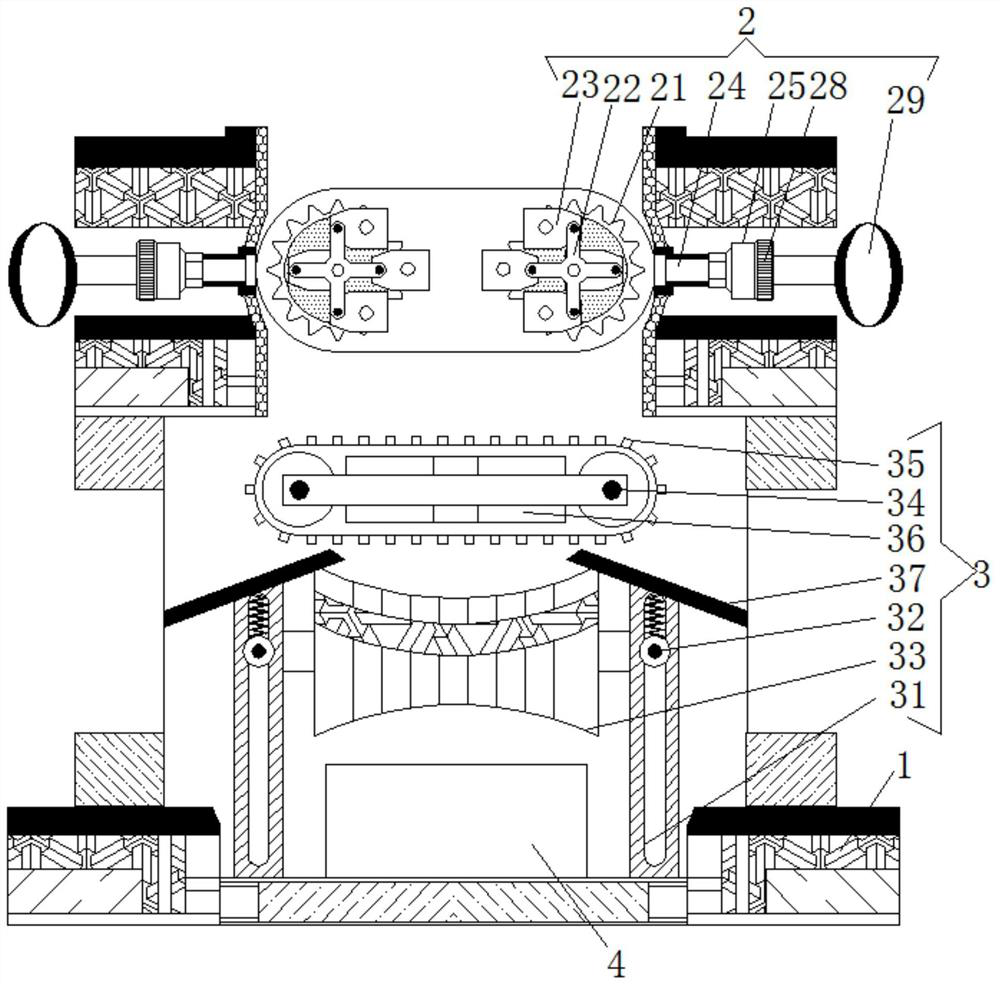

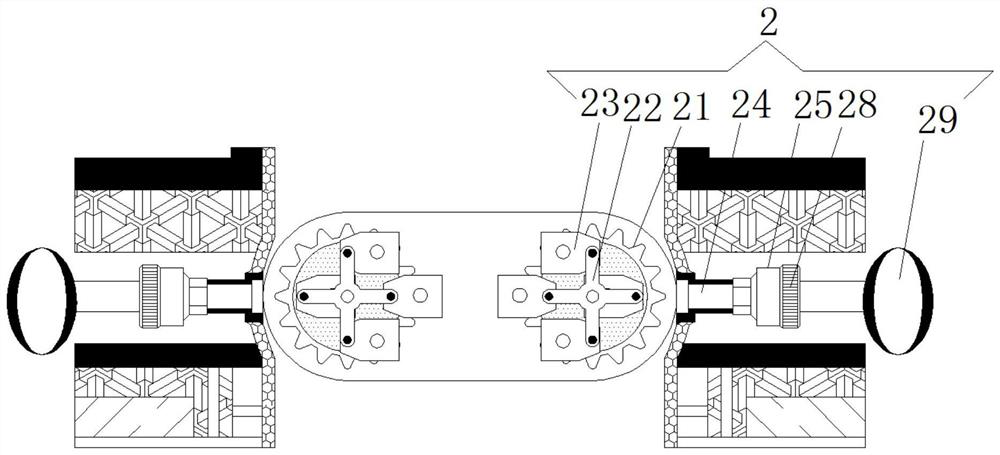

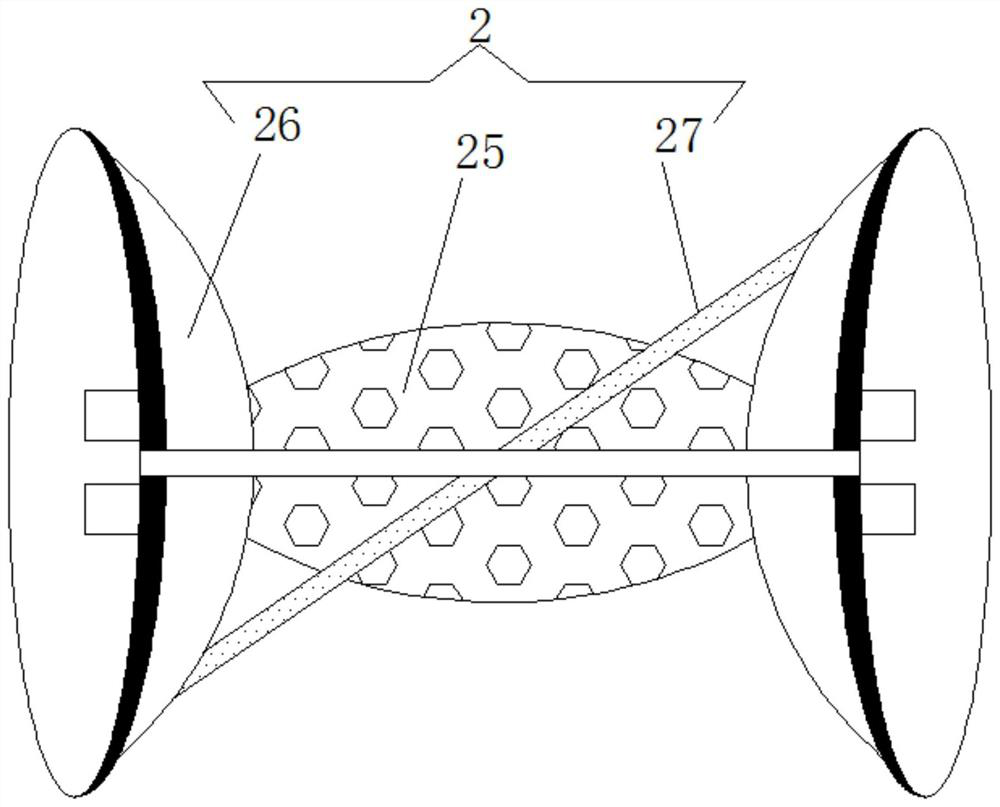

[0025] see Figure 1-3 , a cleaning device for removing impurities in rice, comprising a device main body 1, a dust suction mechanism 2 is fixedly installed on the top of the device body 1, and the dust suction mechanism 2 includes a rotating gear 21, a cross bracket 22, a swing block 23, a dust suction Pipe 24, ellipse column 25, limit semicircle 26, slide plate 27, dust net 28, dust bag 29, the front of rotating gear 21 is connected with cross bracket 22, the back side of cross bracket 22 is connected with swing block 23, the main body of equipment 1 The interior of the dust suction pipe 24 is fixedly installed with an elliptical cylinder 25 fixedly connected to the inside of the dust suction pipe 24, and the outer periphery of the elliptical cylinder 25 is connected with a limited semicircle 26, and the inner wall of the limited semicircle 26 is provided with an air inlet and an air outlet. The front of the post 25 is rotatably connected with a sliding plate 27, the inner w...

Embodiment 2

[0027] see Figure 4 , a cleaning device for removing impurities in rice, comprising a device main body 1, a dust suction mechanism 2 is fixedly installed on the top of the device main body 1, and a metal suction mechanism 3 is fixedly connected to the inside of the device main body 1, and the metal suction mechanism 3 includes a sliding Groove 31, stretching sliding block 32, rolling wheel 33, rotating wheel 34, restriction block 35, permanent magnetic block 36, metal conveying plate 37, the inner sliding connection of chute 31 is connected with stretching sliding block 32, stretching sliding block 32 One end away from the chute 31 is rotatably connected with a scroll wheel 33, one side of the scroll wheel 33 is provided with a metal block, and a filter hole is arranged inside, the interior of the device main body 1 is rotatably connected with a rotatable wheel 34, and the periphery of the rotatable wheel 34 is rotatably connected There is a limiting block 35, a permanent mag...

Embodiment 3

[0029] see Figure 1-4 , a cleaning device for removing impurities in rice, comprising a device main body 1, a dust suction mechanism 2 is fixedly installed on the top of the device body 1, and the dust suction mechanism 2 includes a rotating gear 21, a cross bracket 22, a swing block 23, a dust suction Pipe 24, ellipse column 25, limit semicircle 26, slide plate 27, dust net 28, dust bag 29, the front of rotating gear 21 is connected with cross bracket 22, the back side of cross bracket 22 is connected with swing block 23, the main body of equipment 1 The interior of the dust suction pipe 24 is fixedly installed with an elliptical cylinder 25 fixedly connected to the inside of the dust suction pipe 24, and the outer periphery of the elliptical cylinder 25 is connected with a limited semicircle 26, and the inner wall of the limited semicircle 26 is provided with an air inlet and an air outlet. The front of the post 25 is rotatably connected with a sliding plate 27, the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com