Improved vertical flow precipitation device

An improved vertical flow sedimentation technology, which is applied to the feeding/discharging device of the settling tank, sedimentation separation, chemical instruments and methods, etc., can solve the problems of easy to leave dead ends, time-consuming and laborious sludge speed, etc., and reduce labor Management costs, effects of avoiding the growth of mosquitoes and moss algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

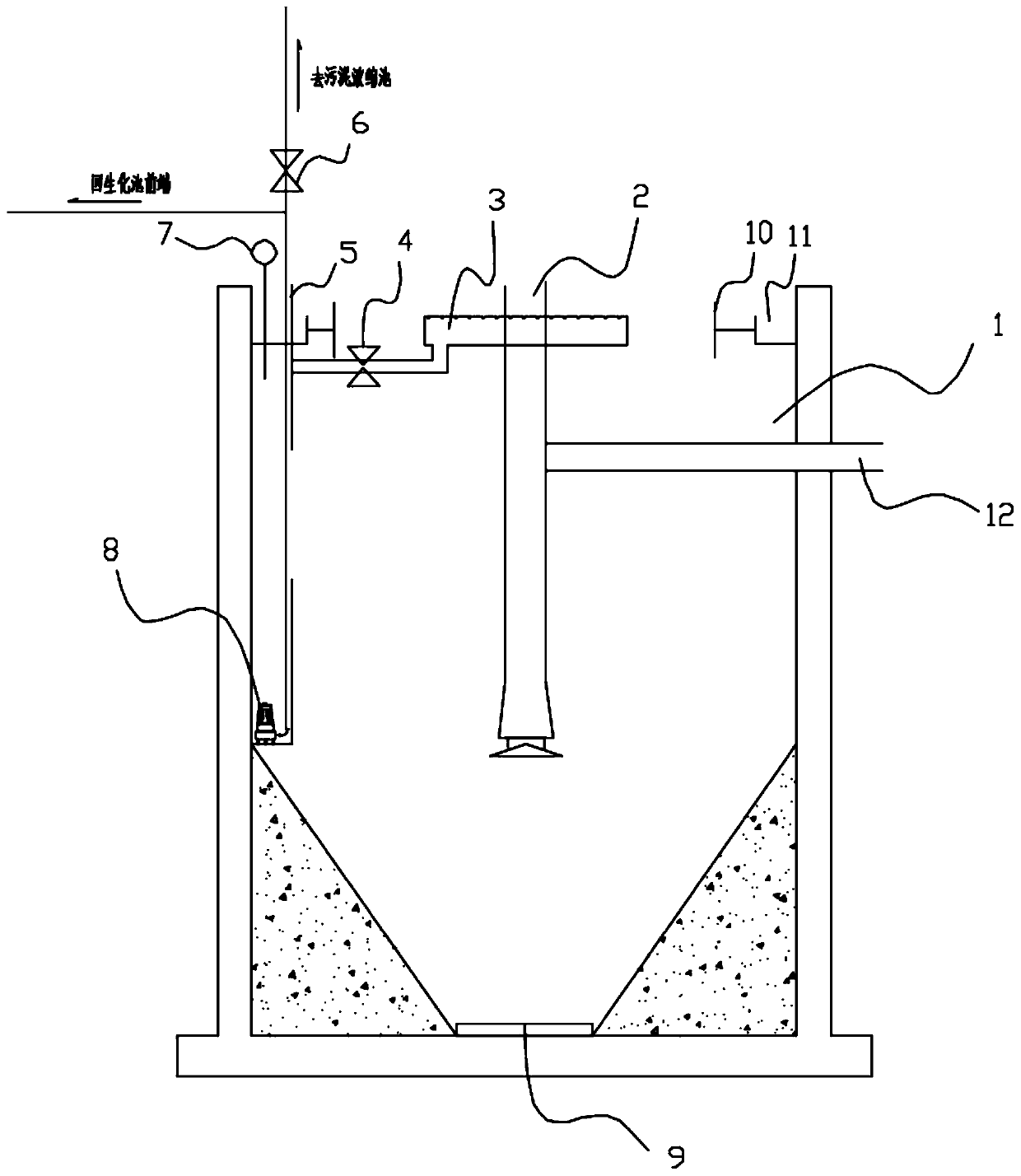

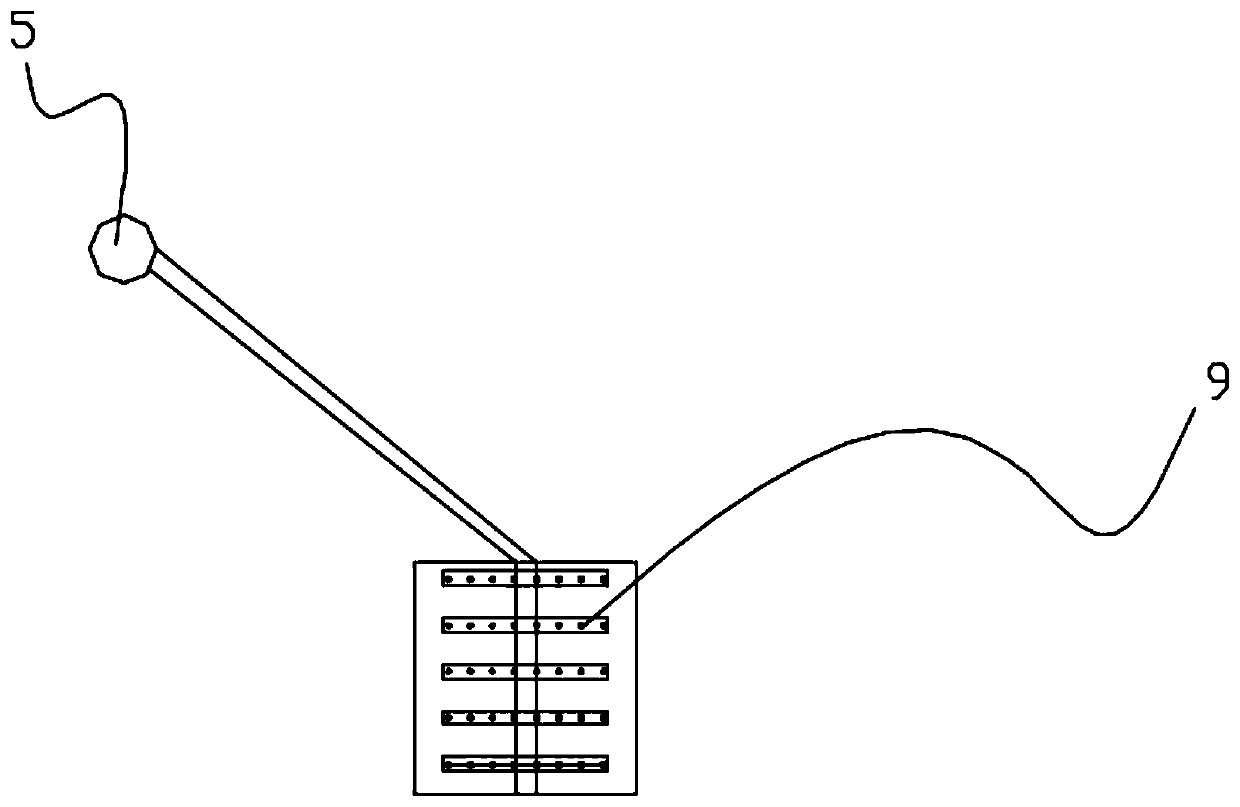

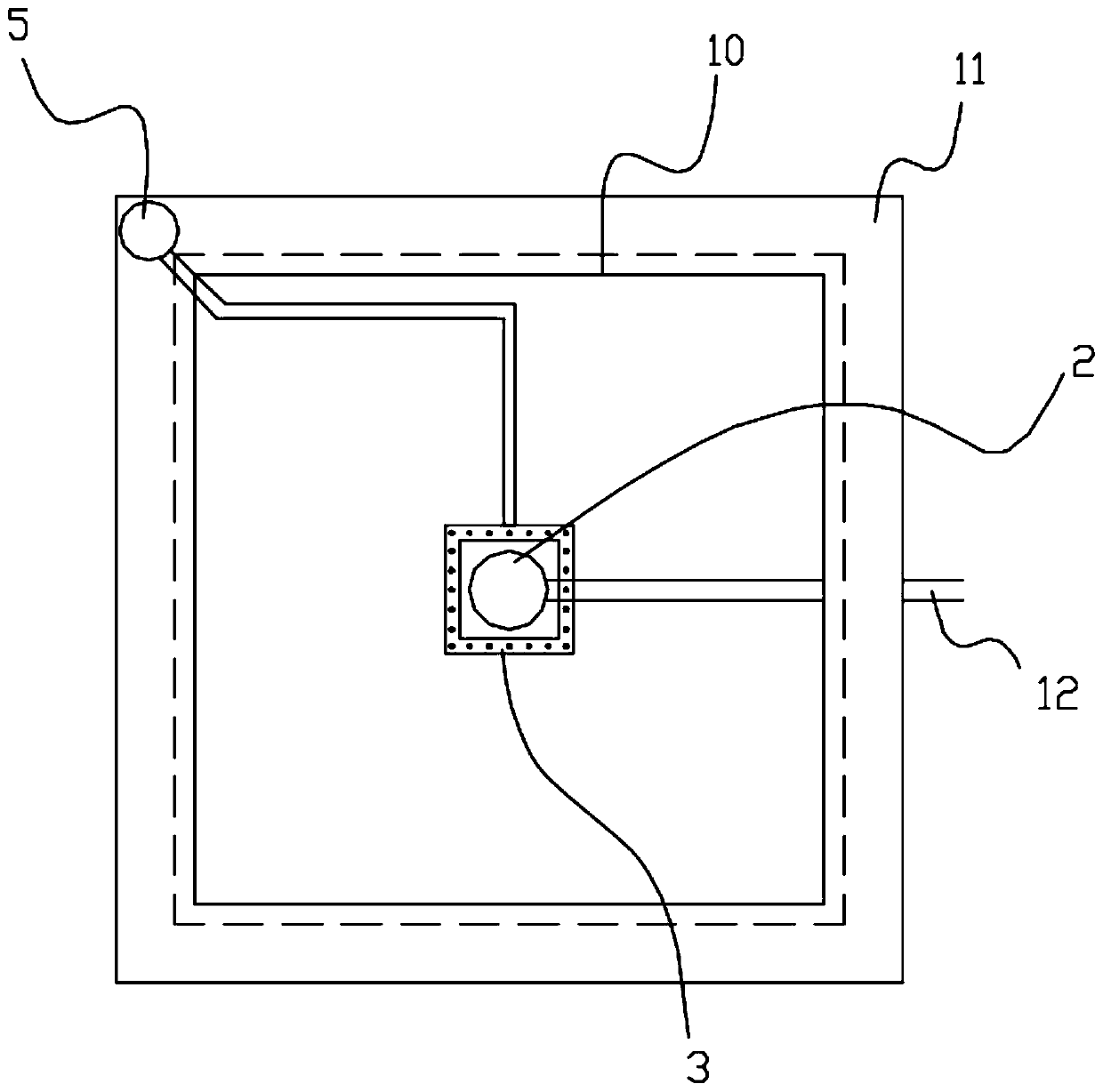

[0027] An improved vertical flow sedimentation device, including a sedimentation tank 1, the interior of the sedimentation tank 1 is a funnel-shaped structure, the bottom of the sedimentation tank 1 is provided with a first mud collecting pipe 9, and the first mud collecting pipe 9 is distributed in the shape of Feng, Offer some mud-suction holes on the first mud-collecting pipe 9, and some mud-suction holes are distributed in two rows and are arranged symmetrically about the axis of the first mud-collecting pipe 9. One end of the first mud-collecting pipe 9 is a closed structure and the other end is Open structure, the opening end of the first mud collecting pipe 9 is connected to the mud collecting tube 5, and the bottom of the mud collecting tube 5 is provided with a sludge pump 8;

[0028] Settling tank 1 is provided with a central cylinder 2, and a gap is provided between the lower part of central cylinder 2 and the first mud collecting pipe 9, so that the liquid phase and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com