Dust suppression spraying device for coal transportation

A spraying device, coal technology, applied in the direction of spraying devices, liquid spraying devices, railway auxiliary equipment, etc., can solve the problems of inability to adjust, increase the labor intensity of staff, waste resources and spray height, and achieve the effect of avoiding spraying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

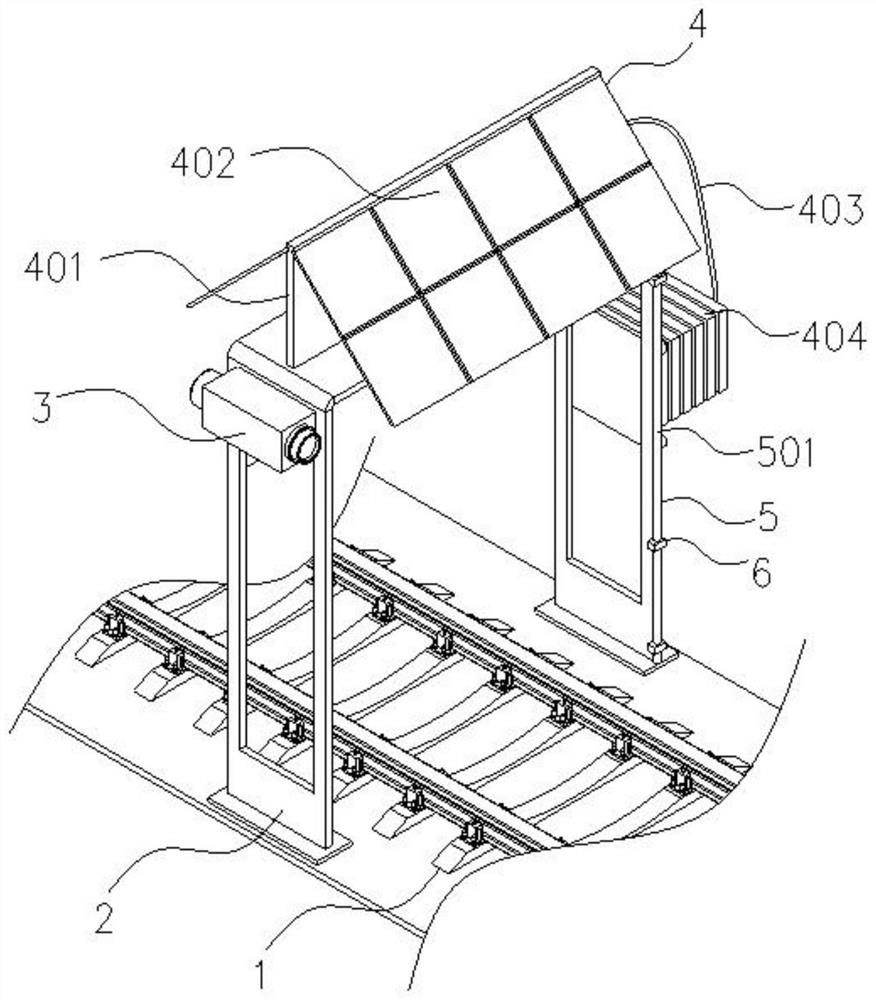

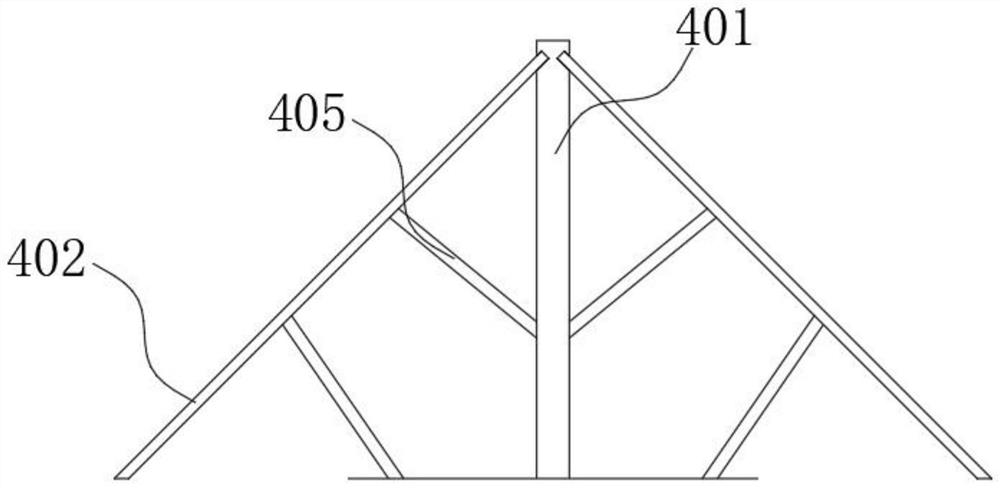

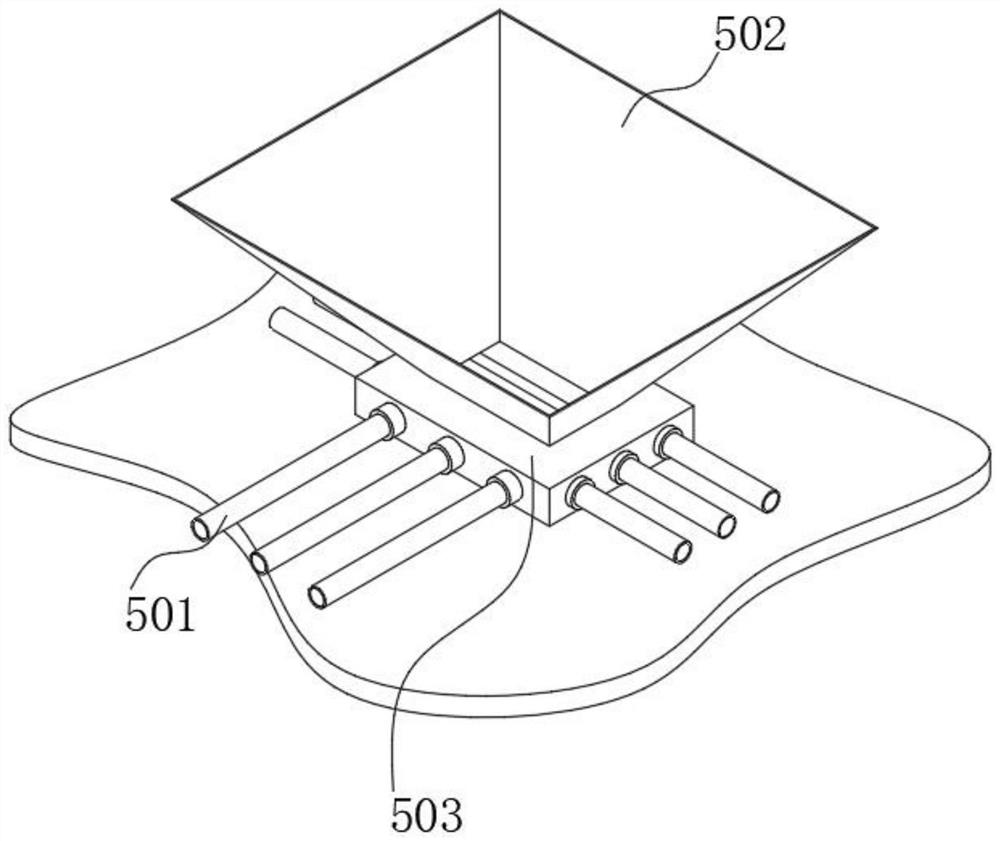

[0037] see Figure 1-9As shown, the present invention is a dust suppression spraying device for coal transportation, including a mounting frame 2, a remote monitoring camera 3 is fixedly connected to the upper part of one side of the mounting frame 2, and an energy mechanism 4 is fixedly connected to the upper part of the other side of the mounting frame 2. The electric storage box 404, the electric storage box 404 is electrically connected with the solar panel 402 through the wire 403, and the solar panel 402 is fixedly connected with the vertical board 401 through the support 405, and the vertical board 401 is fixedly connected at the center position of the top of the installation frame 2, And the edge of one side of the mounting bracket 2 is fixedly connected with the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com