Large hinge type watertight door

A hinged, watertight door technology, applied in the field of watertight doors, to achieve the effect of compact structure, convenient operation, and accurate closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0025] The large hinged watertight door in the present invention refers to a hinged watertight door with a door body width greater than 1.5m.

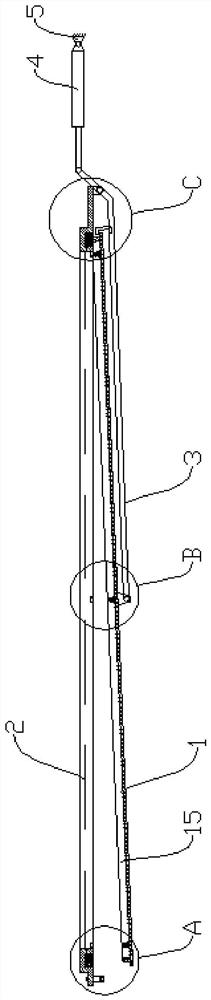

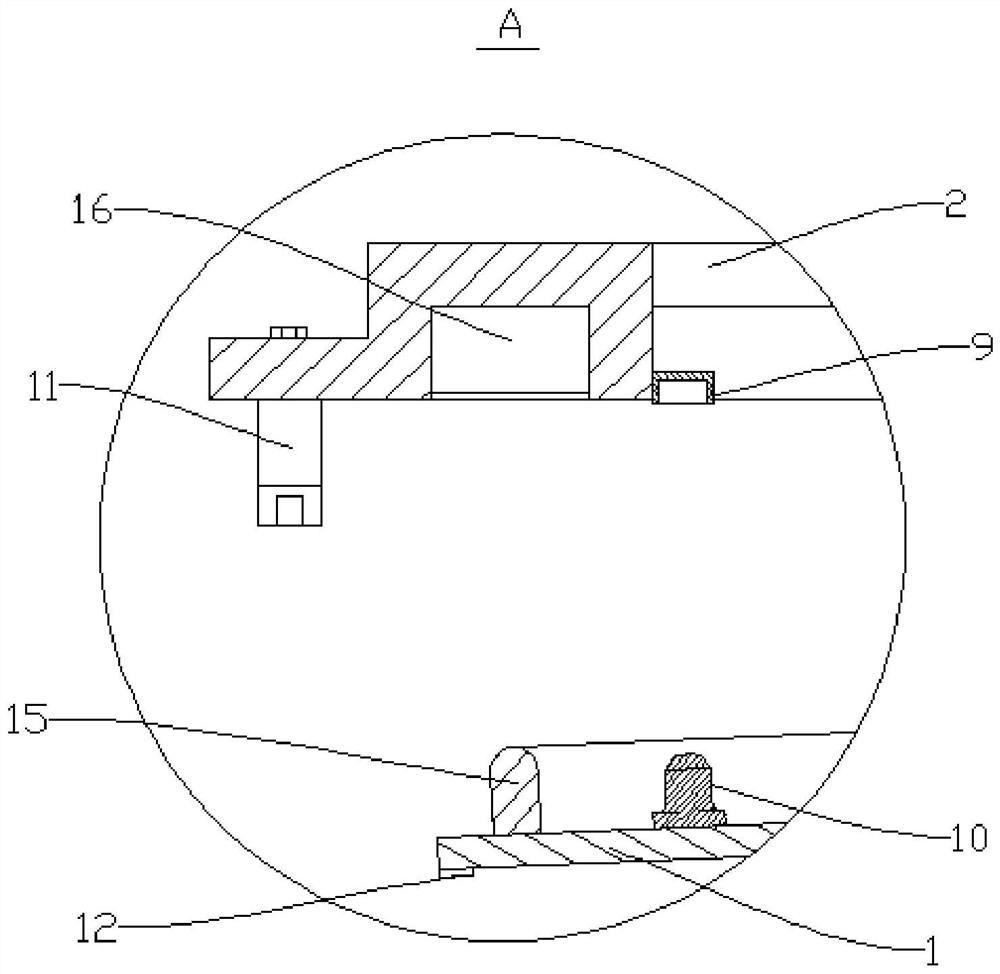

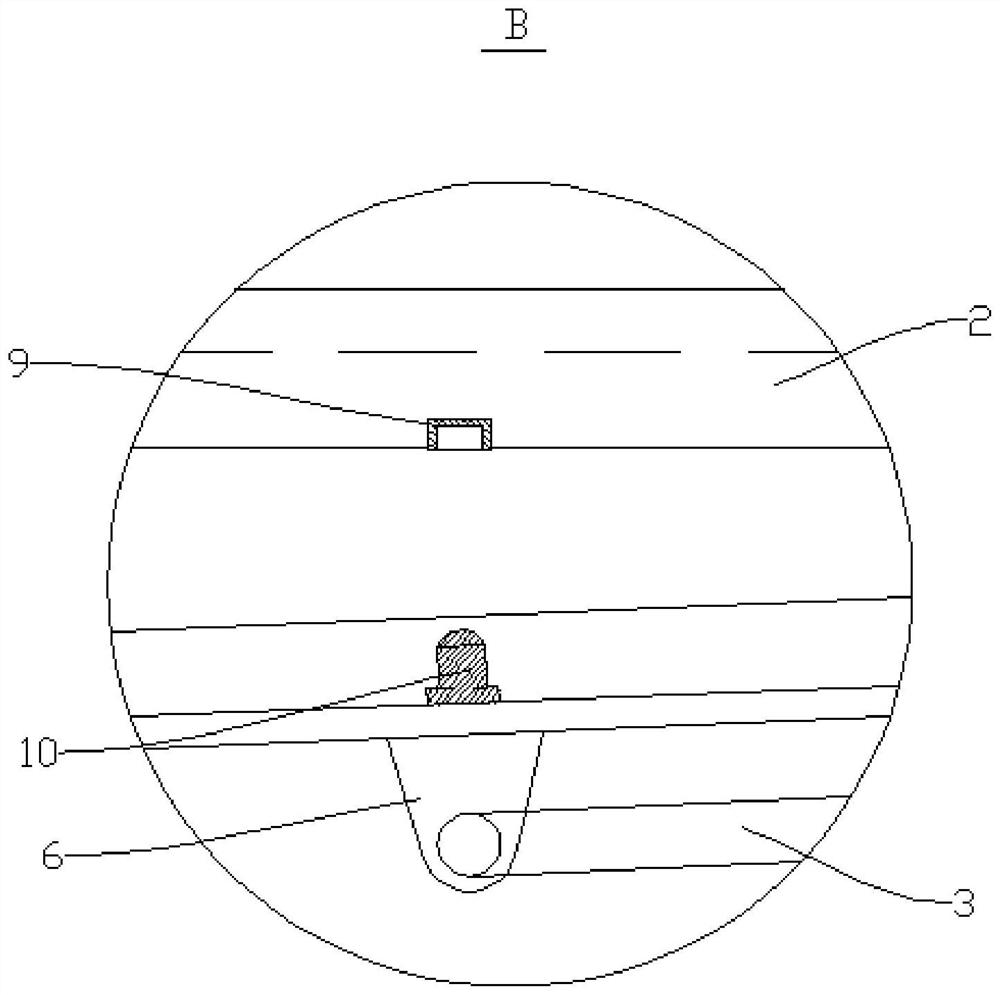

[0026] Such as figure 1 and image 3 In the shown embodiment, a large hinged watertight door mainly includes a door frame 2 and a door body 1 capable of sealing the door frame 2. A first rocker support 6 is provided at the center of the end face of the door body 1 facing away from the door frame 2. One end of the rocking bar 3 is hinged by a pin shaft on a rocking bar support 6, and the other end of the rocking bar 3 is hinged to the driving end of the drive assembly by a pin shaft. A bending part is arranged on the rocking bar 3, and the second rocking bar support 7 is hinged at the position of the bending part through a pin shaft, and the second rocking bar support 7 is arranged on the door fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com