Sushi vinegar acetic acid bacterium, method for fermenting sushi vinegar and application of sushi vinegar acetic acid bacterium in sushi

A technology for sushi vinegar and acetic acid bacteria, which is applied in the field of microbial separation and fermentation, can solve the problems of separation and research of unfermented strains, and achieves the effects of excellent alcohol resistance, bright brown and yellow color, and comfortable aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

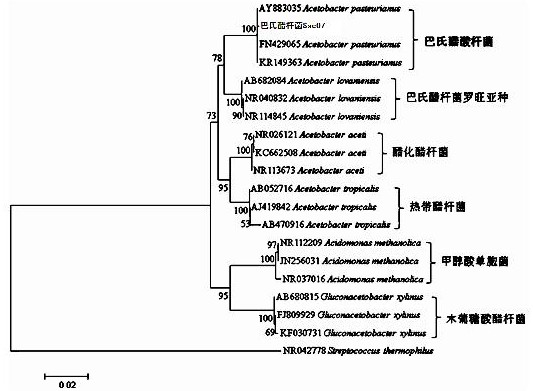

[0036] Example 1 The screening of Acetobacter pasteurianus Ssc07 was obtained

[0037] (1) Microbial enrichment culture

[0038] Take 1-3 g samples of vinegar fermented grains fermented with Japanese white chrysanthemum vinegar for the 3rd to 6th day. The sampling position is 15 cm away from the surface of vinegar fermented grains. The count was 180 rpm, and the enrichment culture was carried out at 42°C for 36 hours.

[0039] Enrichment medium composition: glucose 20 g / L, yeast extract 15 g / L, ethanol 4% (v / v), acetic acid 5 g / L.

[0040] (2) Gradient screening with acetic acid and ethanol for continuous enrichment and purification

[0041]Transfer the fermented liquid obtained in the above step (1) to a 10% (v / v) inoculum into a shaker flask containing 100 mL of enrichment medium, and place the shaker at 180 rpm at 35 °C Under the conditions of enrichment culture, after 36 hours, transfer to fresh enrichment medium.

[0042] The composition of enrichment medium is: gluco...

Embodiment 2

[0047] Embodiment 2 Performance analysis of Acetobacter pasteurianus Ssc07 fermentation product

[0048] (1) Preparation of seed solution

[0049] Acetobacter pasteurii Ssc07 was inoculated from the slant into the seed medium, cultured on a shaker at 37 °C and 160 rpm for 24 hours, and transferred to Scale-up in fresh seed medium.

[0050] Seed medium composition: glucose 20 g / L, yeast extract 15 g / L, ethanol 3.5% (v / v).

[0051] (2) Acetic fermentation

[0052] According to the inoculum amount of 10% (v / v), the seed solution of Acetobacter pasteurii Ssc07 obtained in (1) was respectively inoculated into fermenters for acetic acid fermentation. During the fermentation process, the fermentation temperature was controlled at 37 °C, and the ventilation rate was 1:0.1 (v / v) / min.

[0053] The composition of the fermentation medium was: glucose 30 g / L, yeast extract 20 g / L, ethanol 7% (v / v), acetic acid 10 g / L, MgSO 4 0.1 g / L, CaCl 2 0.2 g / L.

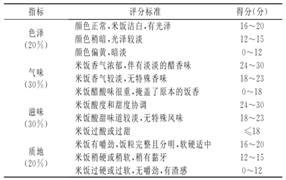

[0054] Using Acetobacter past...

Embodiment 3

[0064] Example 3 Production of sushi vinegar by fermentation of Acetobacter pasteurianus Ssc07

[0065] (1) Raw material pretreatment: select sugar-containing raw materials without mildew and impurities, remove impurities, wash and dry the soil and microorganisms on the sugar-containing raw materials with clean water, crush them, and pass through a 60-mesh sieve; The raw materials used in the fermentation are rice, millet, sorghum, corn (the weight ratio is about 50:10:10:10), supplemented with apples and hawthorn (the weight ratio is about 5:1), and the grain and fruit The ratio, 90:10 by weight.

[0066] (2) Add 10 times the weight of water to the pulverized raw material, and add commercial high-temperature amylase, raise the temperature to 80°C, maintain the pH at 6.0, and keep it warm for 45 minutes;

[0067] (3) Add commercial refined koji to the bran, and ferment for 40 hours at 35°C;

[0068] (4) Mix the above-mentioned pretreated sucrose-containing raw materials and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com