Locking device and method for maintenance of ship chamber of ship lift

A technology of locking device and ship lift, which is applied in the direction of ship lifting device, vertical lifting of ship machinery, construction, etc. It can solve the lack of parking protection device in the ship compartment, and can not affect the normal lifting operation of the ship lift compartment and the safety of the ship compartment. high risk issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

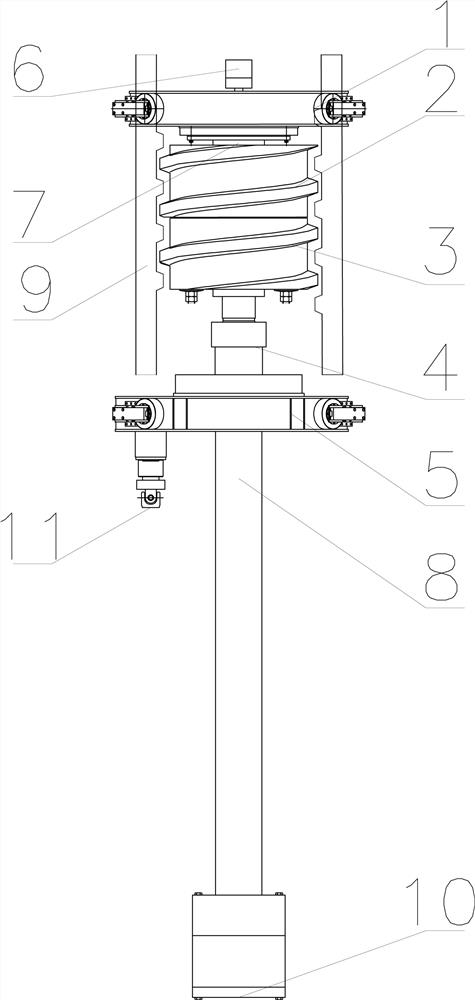

[0044] Such as figure 1 As shown in the figure, a locking device for ship lift cabin maintenance includes an upper guide frame system 1, an upper locking block 2, a lower locking block 3, a transmission shaft 4, a lower guide frame system 5, a rotation adaptation mechanism 6, and a rotation center rod 7. Hinged support shaft 8, nut column 9, ship box structure 10, ship box transmission system 11. Specifically, the transmission shaft 4 is located at the upper end of the hinged support shaft 8 , and the transmission shaft 4 can rotate relative to the hinged support shaft 8 . The lower guide frame system 5 is installed and matched with the lower part of the transmission shaft 4, and the lower guide frame system 5 is driven to rotate by the cabin transmission system 11 and then drives the transmission shaft 4 to rotate. The rotation center rod 7 is fixedly connected to the upper end of the transmission shaft 4, and the rotation center rod 7 also rotates during the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com