Steel pipe forming device

A forming device and steel pipe technology, applied in the field of mold sets, can solve problems such as the steel pipe is not firm, and achieve the effect of ensuring effective bending, avoiding edge warping, and avoiding the influence of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

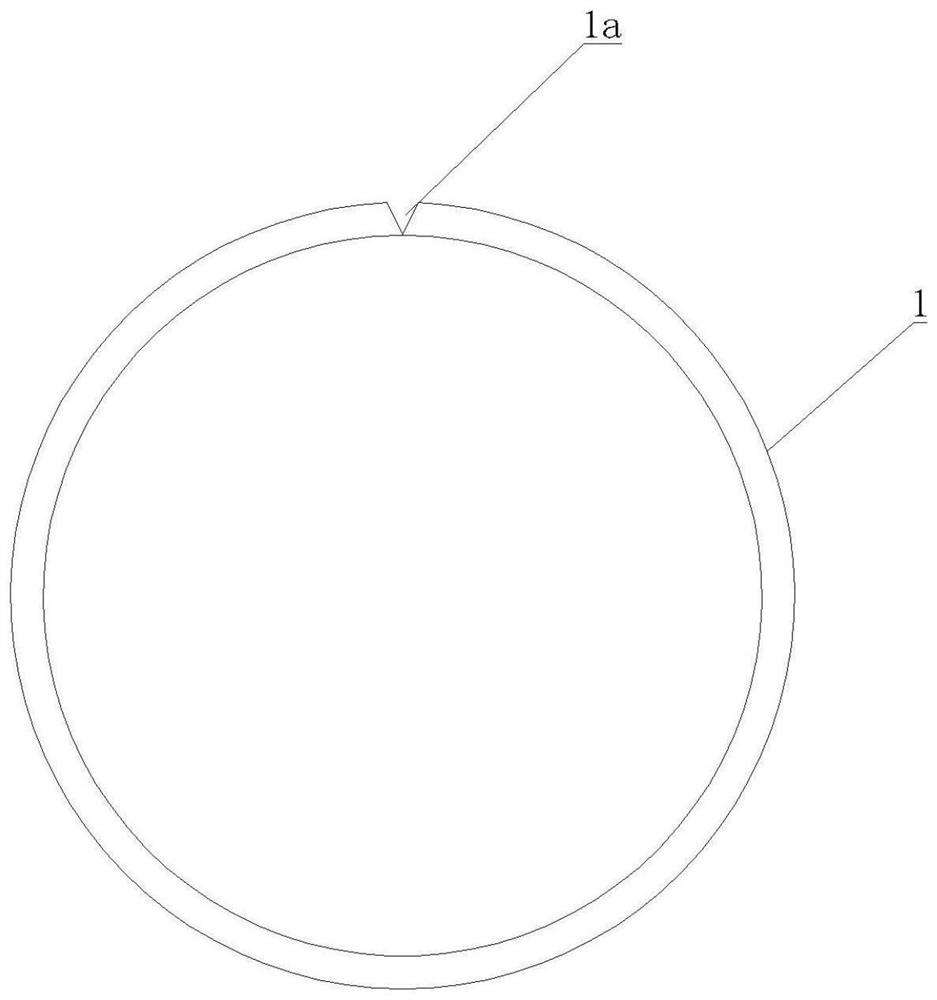

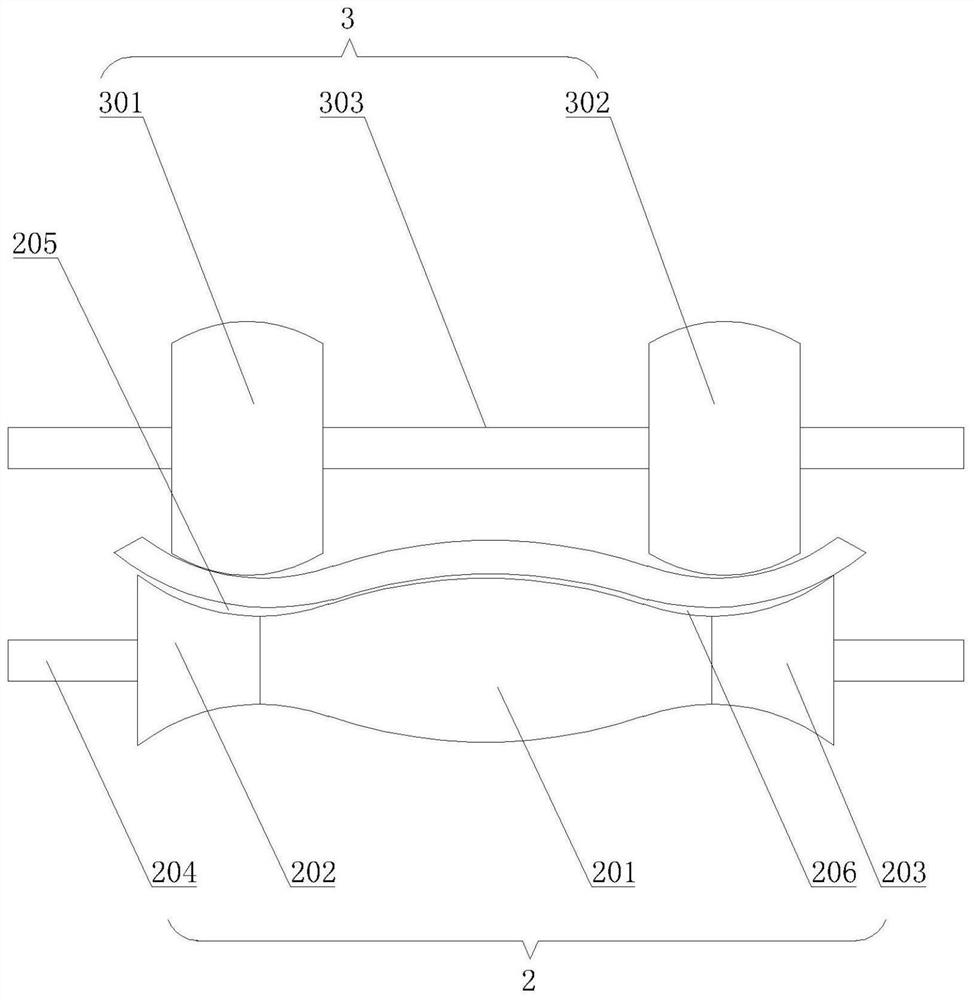

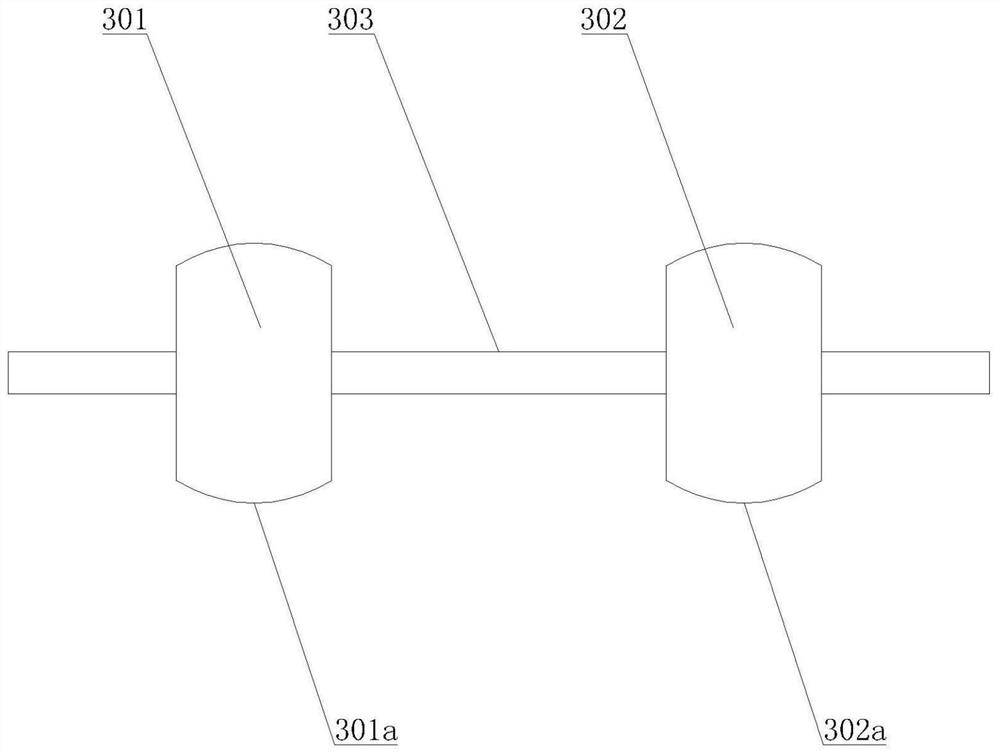

[0034] Such as Figure 1-9 As shown, a steel pipe forming device includes a steel plate crimping device and a steel pipe forming device. The steel pipe surface heat treatment device is provided at the discharge end of the steel pipe forming device. The steel pipe surface heat treatment device includes a base 501 on which a There is a support box 502, and the support box 502 is provided with a processing pipe 512. The steel pipe 512 extends from one end of the processing pipe 512 into the processing pipe 512. The steel pipe 1 extends from the other end of the processing pipe 512. The processing pipe 512 One end is provided with a first sealing mechanism, and the other end of the processing pipe 512 is provided with a second sealing mechanism, and the processing pipe 512 is connected with an inert gas delivery pipe 511; it also includes a vortex heating device, and the eddy current heating device includes a The transformer box 503 on the box 502 is provided with a positive pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com