Pipe bending mechanism capable of coping with various bending modes and bending machine

A technology of bending and different types of pipes, applied in the field of heat transfer pipes, can solve the problems of pipe-taking interference, affecting production efficiency, affecting the pipe-taking speed, etc., and achieves the effect of high speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

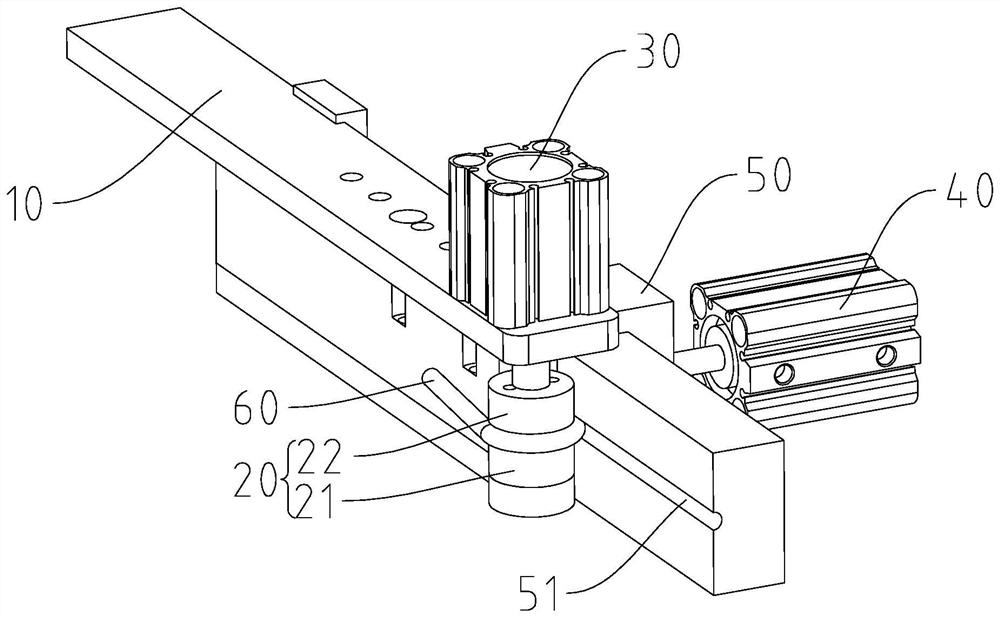

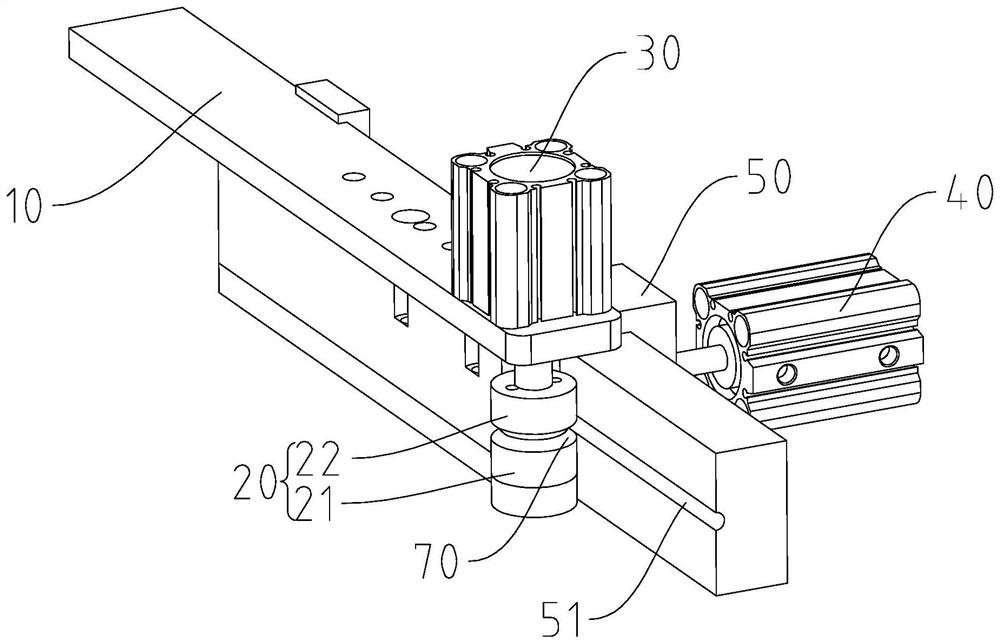

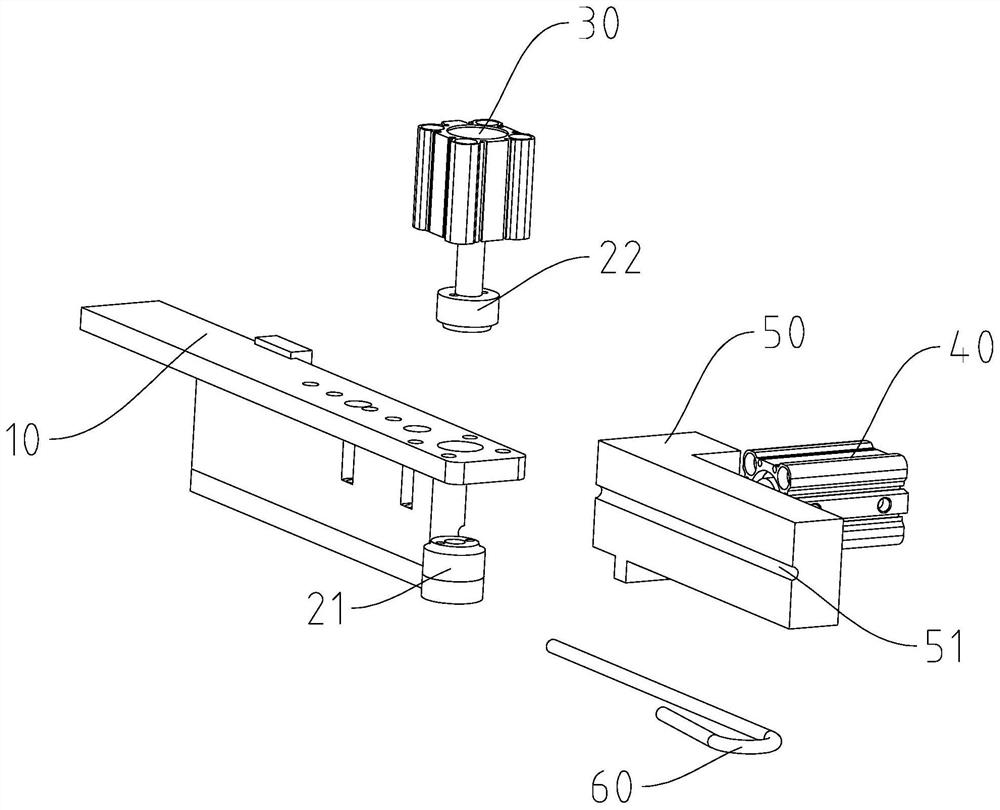

[0017] like Figure 1 to Figure 4 As shown, it is a structural schematic diagram of a pipe bending mechanism and a bending machine that can cope with various bending methods provided by the present invention. A pipe bending mechanism capable of coping with various bending methods, used for bending heat pipes, including a pipe bending fixture 10, a pipe bending center wheel 20, a first driving device 30, a second driving device 40 and a clamping block 50, The pipe bending center wheel 20 is located at one end of the pipe bending fixture 10, and the pipe bending center wheel 20 includes a lower mold 21 fixedly connected with the pipe bending fixture 10 and an upper mold located above the lower mold 21 22. The first dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com