Medicine dispensing machine and dispensing machine medicine groove position deviation correction method

A medicine dispensing machine and medicine tank technology, which is applied to storage devices, transportation and packaging, etc., can solve the problems of cumbersome adjustment methods, time-consuming and laborious, etc., and achieve the effect of automatically correcting the position deviation of the medicine tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

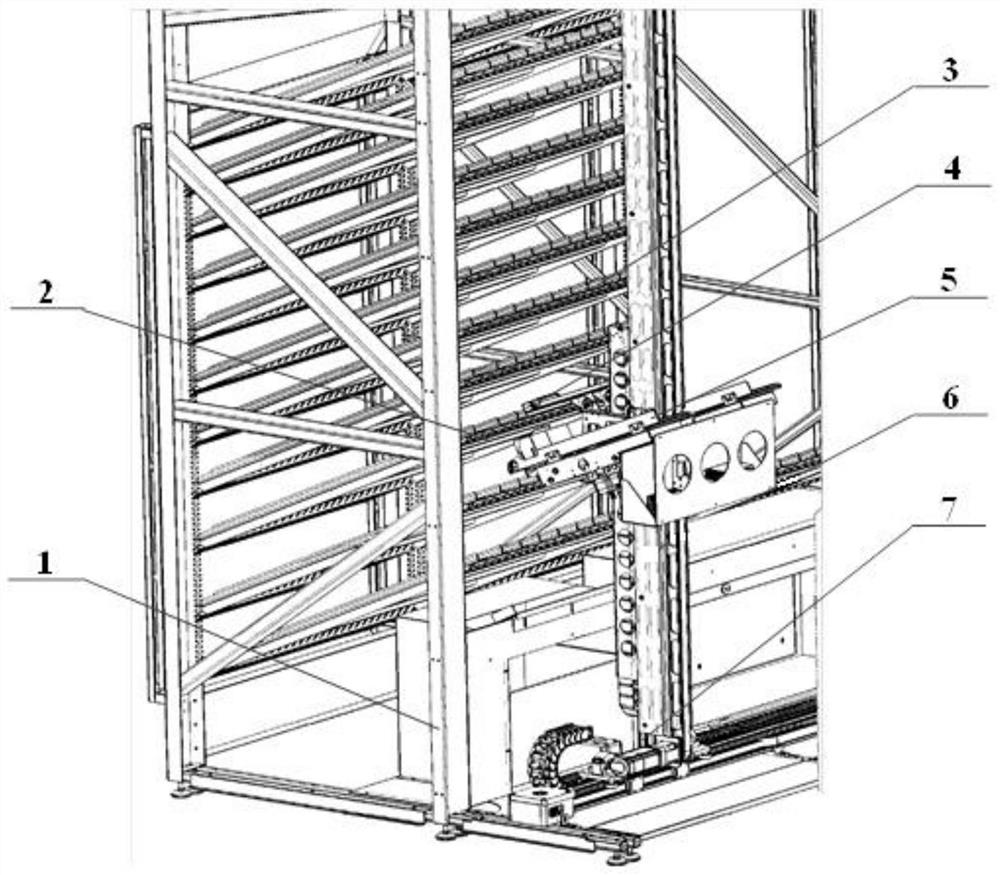

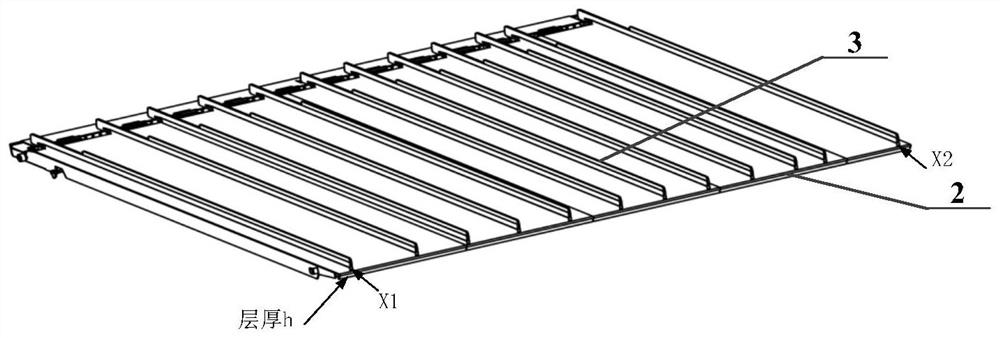

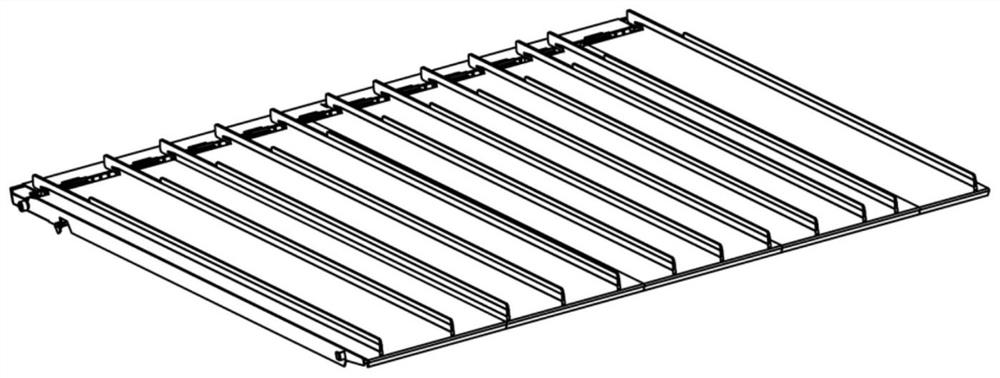

[0028] Example 1 as Figure 1-8 As shown, a drug dispensing machine includes: a manipulator 6, a conveyor belt 7 movably connected to the lower part of the manipulator, and a storage rack. The manipulator 6 is placed on one side of the medicine dispensing machine, and the manipulator 6 drives the conveyor belt to rotate through a servo motor, and the control Horizontal and vertical movement of the manipulator. Said manipulator 6 is equipped with a medicine delivery tank 5, and said manipulator 6 is equipped with an infrared sensor 8 for detecting and judging whether the medicine box slides off from the medicine delivery tank, and the infrared sensor arranged at the bottom of the manipulator is used for medicine storage on the medicine storage layer. When detecting whether the drug is completely slipped into the laminate, it is prevented that the drug is damaged by the movement of the manipulator when the drug is stuck at the position of the sensor. Alternatively, the function...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com