Two-stage oil cylinder

A technology of two-stage oil cylinder and cylinder bottom, which is applied in the direction of fluid pressure actuating device, etc., can solve the problems such as the inability to meet the needs of independent action of pistons at all levels, and achieve the effect of compact structure, reasonable design and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

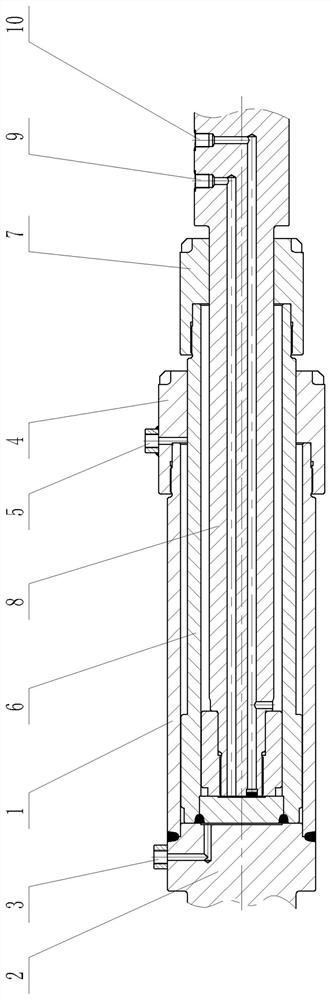

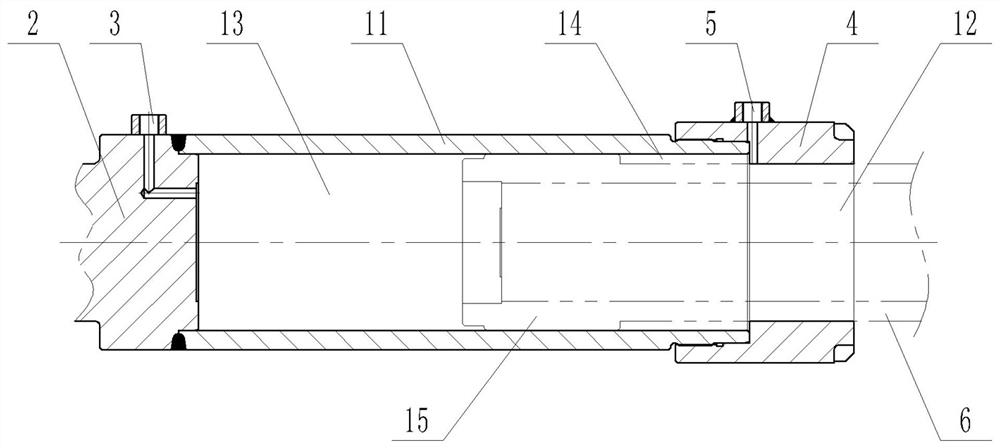

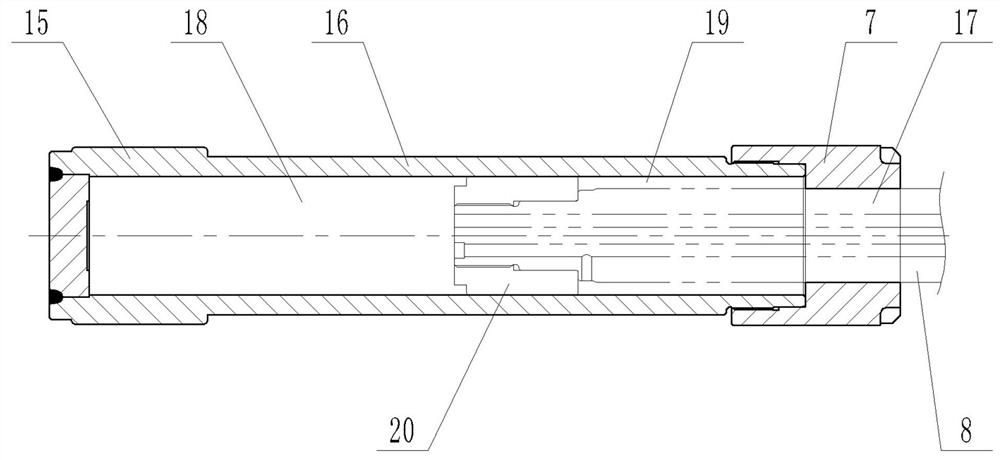

[0023] according to Figure 1-7 The specific structure of the present invention will be described in detail. The secondary oil cylinder includes an outer cylinder body 1 composed of an outer cylinder body 11, the rear end of the outer cylinder body 11 of the outer cylinder body 1 is provided with an outer cylinder bottom 2, and the inner cylinder telescopic socket at the front end of the outer cylinder body 11 There are 12 movable sockets provided with a first-stage inner cylinder body 6, and an outer cylinder guide sleeve 4 is also provided at the inner cylinder telescopic socket 12 of the outer cylinder body 11, and then while sealing the inner cavity of the outer cylinder body 1, the first-stage The expansion and contraction of the inner cylinder body 6 is effectively guided. The first-stage inner cylinder body 6 is composed of an inner cylinder body 16 , which is located at the rear end of the outer cylinder body 1 and is provided with an inner cylinder bottom 15 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com