Combustion chamber test device of aviation gas turbine and test method thereof

An aviation gas turbine and test device technology, which is applied in the direction of gas turbine engine testing, measuring equipment, engine testing, etc., can solve the problems of increasing the difficulty of the work of the staff, inconvenient movement, inconvenient replacement, etc., so as to facilitate the storage and unfolding of the runners , Conducive to installation, increase the effect of stability

Pending Publication Date: 2022-01-28

沈阳航所动力设备有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In the research of the global flow afterburning cycle engine technology, all the hydrogen and helium flow through the pre-combustion chamber are burned once to drive the turbine, and then enter the combustion chamber for secondary combustion.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

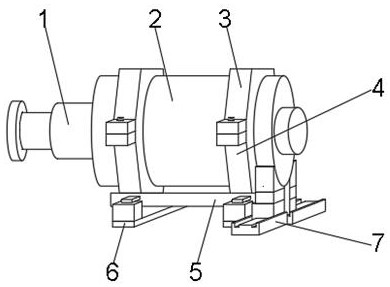

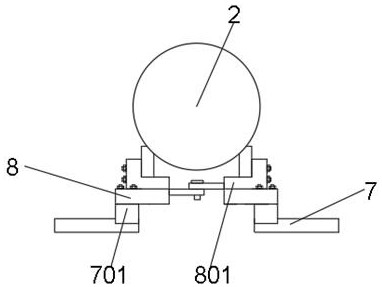

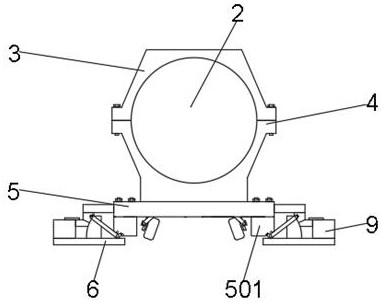

The invention discloses a combustion chamber test device of an aviation gas turbine and a test method thereof. The combustion chamber test device comprises an engine head, wherein an engine body is mounted at the output end of the engine head, and an upper mounting plate and a first bottom plate are arranged at the top of the engine body, a first bottom plate which is arranged at the bottom of a connecting plate, wherein a positioning rod is hinged to one end of the top of the first bottom plate. The device has the beneficial effects that the motor drives the two-way threaded rod to rotate, the two-way threaded rod can drive the guide block and the adjusting plate to move synchronously, the guide block can drive the rotating wheel to rotate through the first transmission rod and the mounting block in the moving process, the rotating wheel is convenient to store and unfold, in the storage process, the adjusting plate can drive the positioning rod of the through hole of the first supporting plate to rotate, the positioning block is inserted into the clamping groove of the fixing plate, the top of the positioning block can be attached to the bottom of the second sliding block, the second sliding block can be fixed through the positioning block, and thus supporting and fixing of the connecting plate are achieved.

Description

technical field [0001] The invention relates to a test device, in particular to a combustion chamber test device of an aviation gas turbine and a test method thereof, belonging to the technical field of the combustion chamber test of the aviation gas turbine. Background technique [0002] Aviation is a complex and strategic human activity, which refers to the flight and navigation activities of aircraft in the earth's atmosphere and air space. The combustion chamber is a device in which fuel or propellant is burned to generate high-temperature gas. It is a durable Combustion equipment made of high-temperature alloy materials, the space between the top of the piston and the cylinder head after the piston reaches the top dead center, the fuel is burned in this room, it is an important part of the gas turbine engine, ramjet engine and rocket engine, composed of diffuser , Combustion chamber shell, flame cylinder, fuel nozzle, ignition device, divided into single-tube combustion...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M15/14G01M15/02

CPCG01M15/14G01M15/02

Inventor 韩崇福卞鈺铁克田金龙苏彬

Owner 沈阳航所动力设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com