Method for constructing reagent compound prediction model, and method and device for automatically predicting and complementing chemical reaction reagents

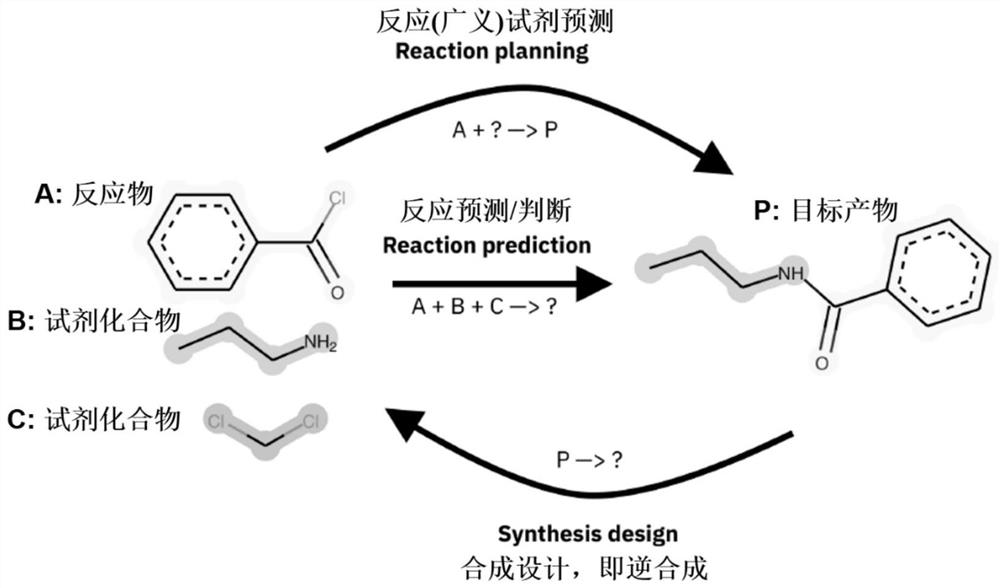

A technology for predicting models and chemical reactions, applied in the field of medicinal chemistry applications, can solve the problem of not containing chemical information, and achieve the effect of improving the accuracy and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

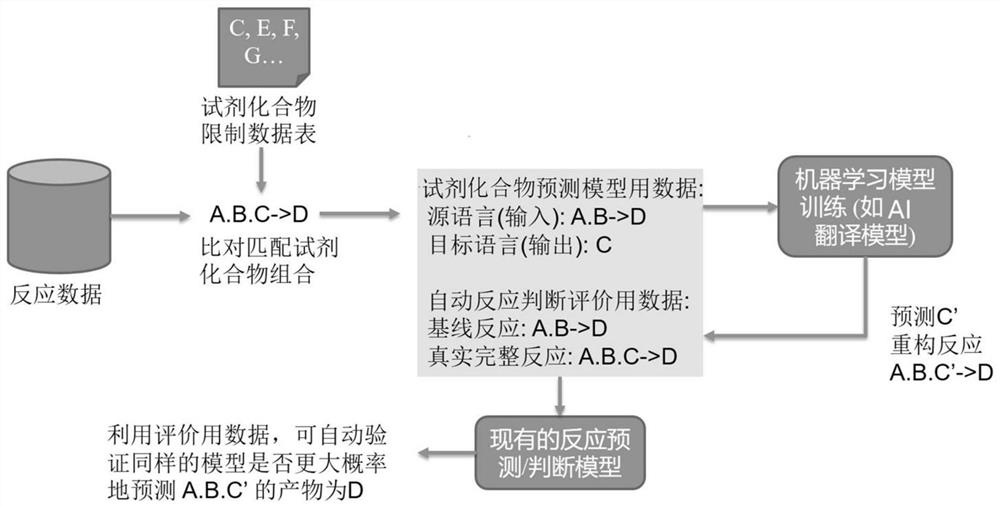

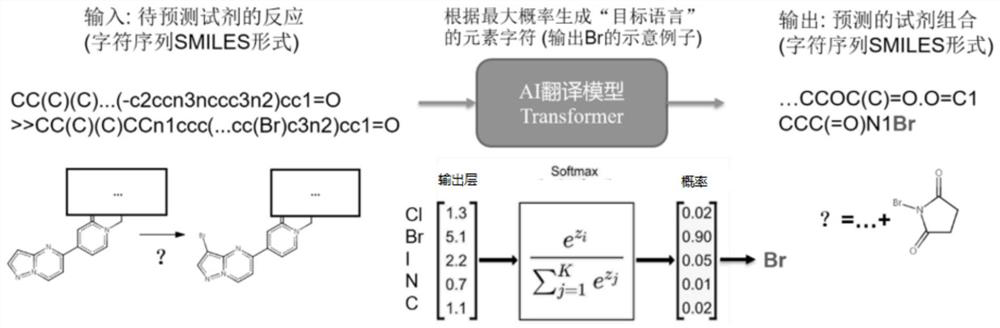

[0055] Machine translation implementation of reagent compound prediction model training: Based on the deep learning machine translation model, the modeling training of reagent prediction is carried out on the constructed missing reagent reaction training data set.

[0056] Step 1, collect relevant chemical reagent standard names, use the open chemical noun conversion tool ( https: / / opsin.ch.cam.ac.uk / ) into SMILES, and merge the reagent SMILES accumulated by other experts to form a "Reagent Compound Restriction Data Table" with >2000 reagent SMILES

[0057] Step 2: collect chemical reaction formulas through public chemical patents and process them into SMILES. A total of 2 million reactions are collected, of which 95% (1.8 million) are used as training sets, and the other 5% (95,000) are used as test sets.

[0058] Step 3. Delete the reagents and their combinations in the "Reagent Compound Limit Data Table" on the existing chemical reaction SMILES data that completely con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com