Flexible slag blowing equipment for cylinder body

A cylinder body and flexible technology, applied in the field of cylinder body flexible slag blowing equipment, can solve the problems of turning over the cylinder body and low efficiency of slag blowing, so as to improve efficiency, reduce labor costs, and prevent repeated cleaning and leakage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

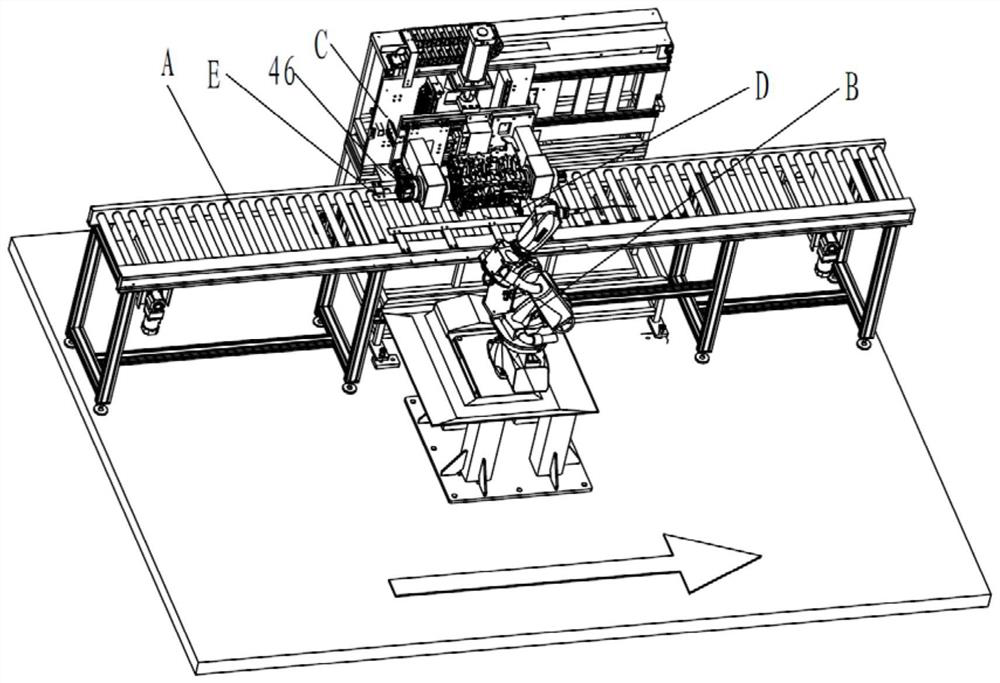

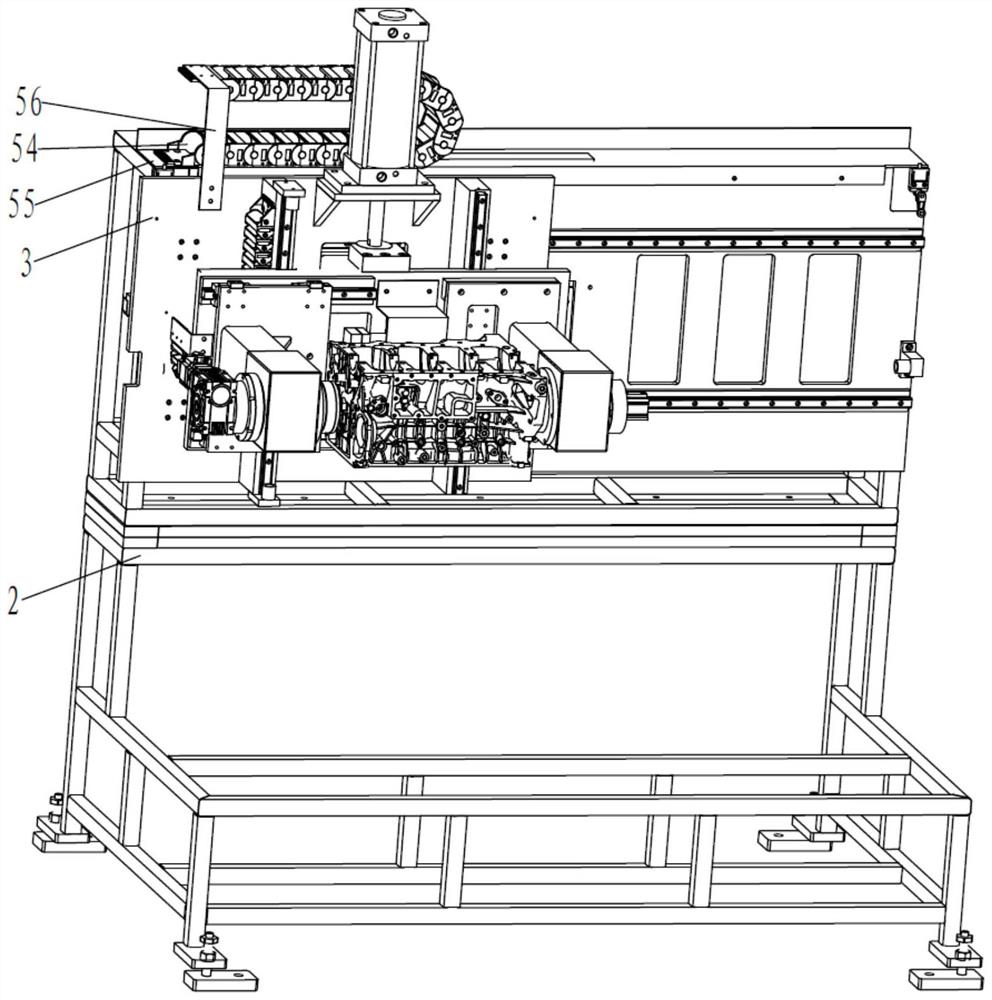

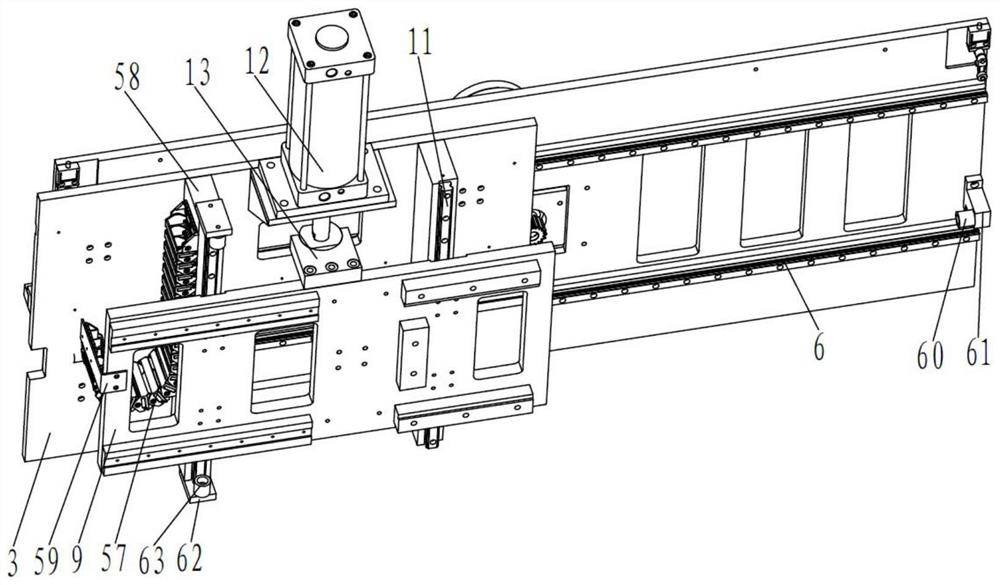

[0031] Such as Figure 1-13As shown, a cylinder flexible slag blowing equipment is mainly composed of a conveyor line A, a robot B and a motion mechanism C, wherein the conveyor line A extends left and right, and a robot B is set in front of the middle of the conveyor line A, and a robot B is set on the robot B. The slender blowing head 1 is provided with a moving mechanism C behind the middle part of the conveying line A, and the moving mechanism C is located behind the robot B. The movement mechanism C includes a clamping and turning mechanism, a moving mechanism and a fixed frame 2, the fixed frame 2 is fixedly arranged on the ground, the moving mechanism is arranged on the fixed frame 2, the clamping and turning mechanism is arranged on the moving mechanism, and the clamping and turning mechanism is used for The cylinder is clamped and flipped, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com