Double-sided multi-cutting-edge threaded blade and cutting tool

A threaded blade, double-sided technology, applied in thread cutting tools, thread cutting devices, manufacturing tools, etc., can solve the problems of cutting tip sharpness reduction, upper cutting tip impact, cutting tip damage, etc. Chips are smooth and sharpness is ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

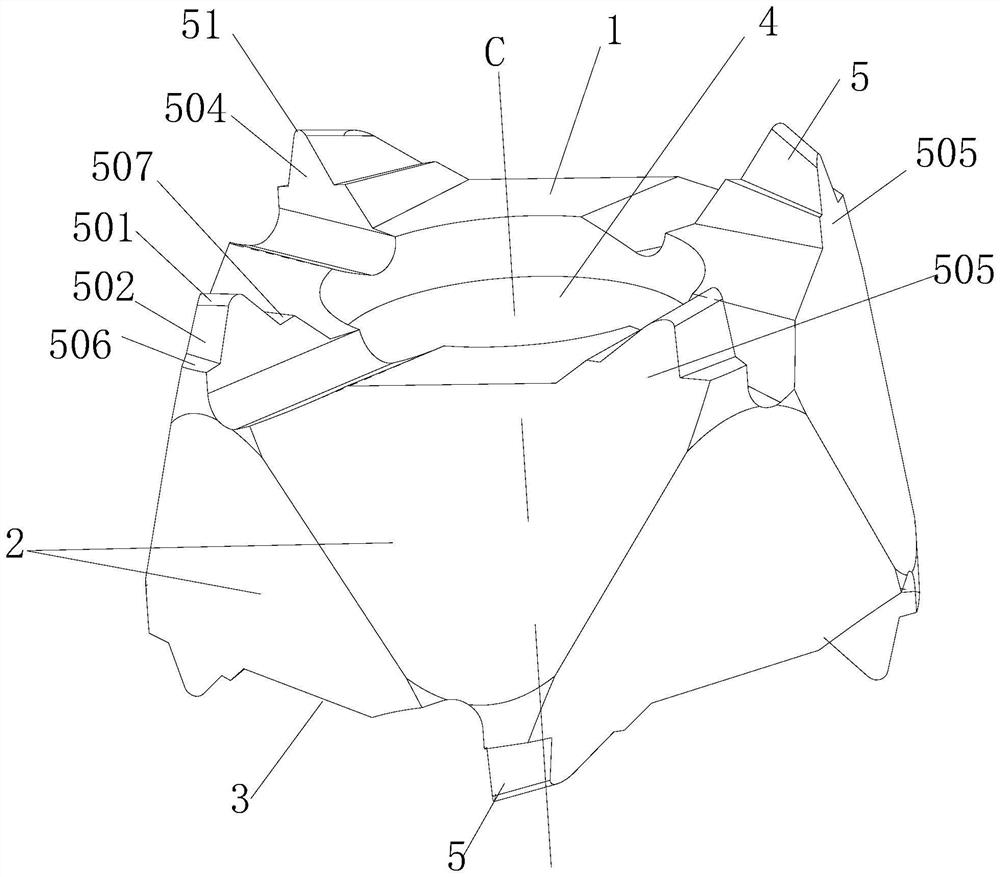

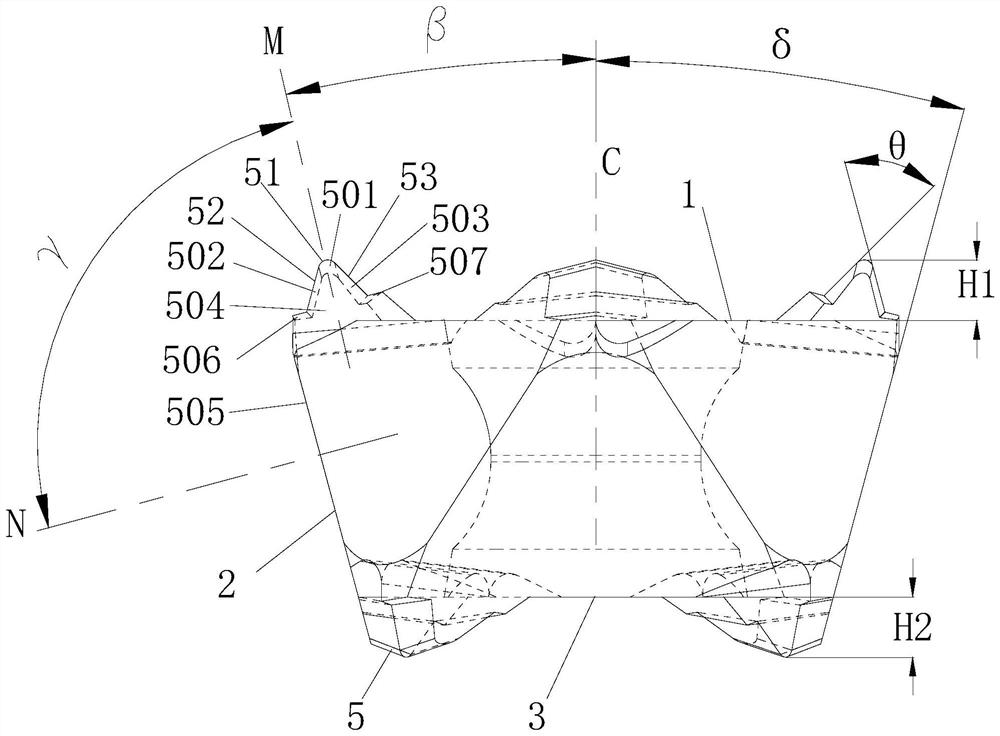

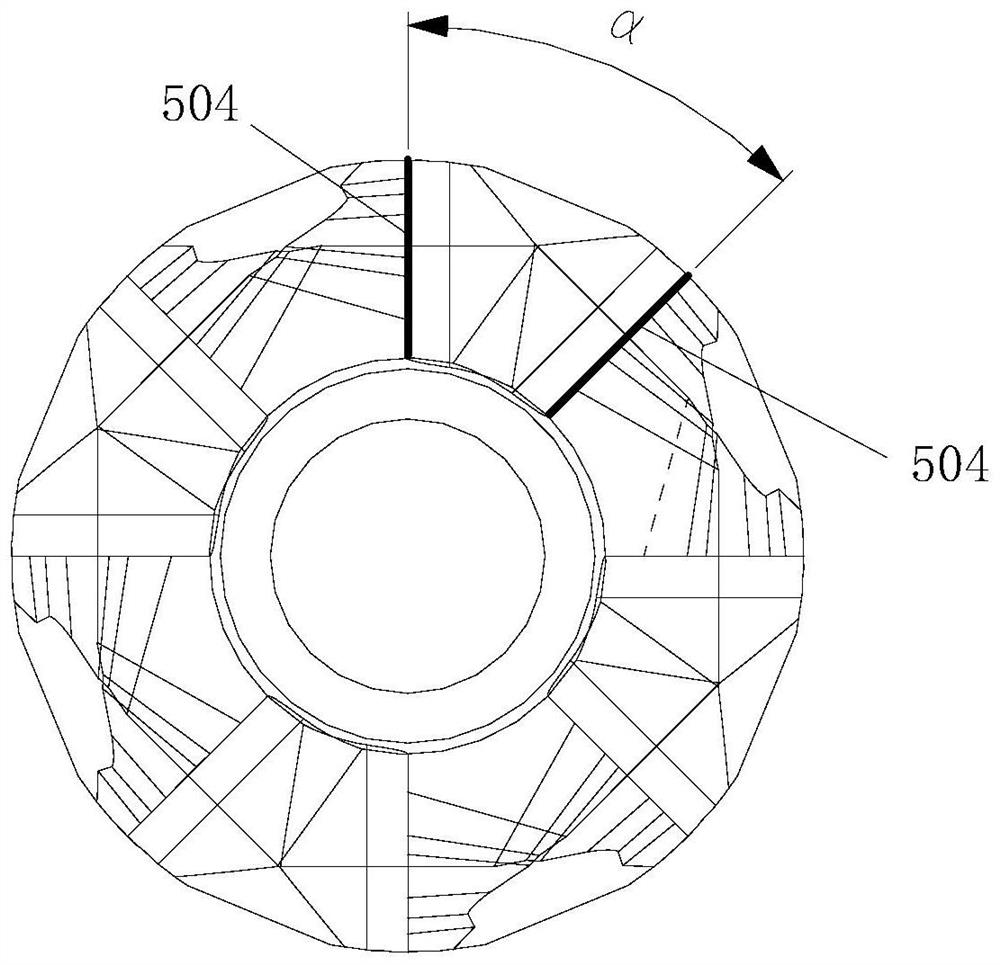

[0026] like Figure 1 to Figure 4 As shown, the double-sided multi-edged threaded insert of this embodiment includes end face 1, end face 2 3 and the main side 2 connected between end face 1 and end face 2 3, and end face 1 is provided with end face 2 3 The clamping hole 4 is provided with a plurality of protruding cutting parts 5 on the end face 1, and a plurality of protruding cutting parts 5 are provided on the end face 2 3, and the number of cutting parts 5 on the end face 1 and the end face 2 3 Similarly, the cutting parts 5 on the end face 1 are evenly arranged along the outer circumference of the clamping hole 4, and the cutting parts 5 on the end face 2 3 are evenly arranged along the outer circumference of the clamping hole 4, and the cutting parts 5 on the end face 1 and the end face The cutting portion 5 on the second 3 is arranged in a dislocation manner, and the cutting portion 5 includes a cutting edge 51 and a first cutting edge 52 and a second cutting edge 53 c...

Embodiment 2

[0039] like Figure 5 As shown, the cutting tool of this embodiment includes a cutter body 6, and also includes the cutting blade of the above-mentioned embodiment 1, the cutter body 6 is provided with a sipe 61, and the cutting blade is installed in the sipe 61 by a fastener 7, fastened Part 7 is located in the clamping hole 4 .

[0040] In this embodiment, the fasteners 7 are preferably bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com