Silicone rubber material for composite insulator and preparation method of silicone rubber material

A composite insulator and silicone rubber technology, applied in the field of composite insulators, can solve problems such as affecting the insulation performance of composite insulators, exposing mandrels, damaging line use and operating life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing the above-mentioned silicone rubber material for composite insulators, comprising the following steps:

[0039] A) mixing rubber base material, white carbon black, hydroxy silicone oil, hydrogen-containing silicone oil, activated aluminum hydroxide, zinc oxide and methyl anthranilate into agglomerates to obtain a mixed rubber compound;

[0040] B) heating the mixed rubber material at a temperature of 140-175° C. and a vacuum of 0.04-0.08 MPa for 1-3 hours, and cooling down to 38-45° C.;

[0041] C) Mix the thinned rubber material, color masterbatch and vulcanizing agent, and filter the rubber after thinning to obtain a silicone rubber material for composite insulators.

[0042] In the preparation method of the silicone rubber material for composite insulators provided by the present invention, the raw material components and proportions used are the same as above, and will not be repeated here.

[0043] In the ...

Embodiment 1

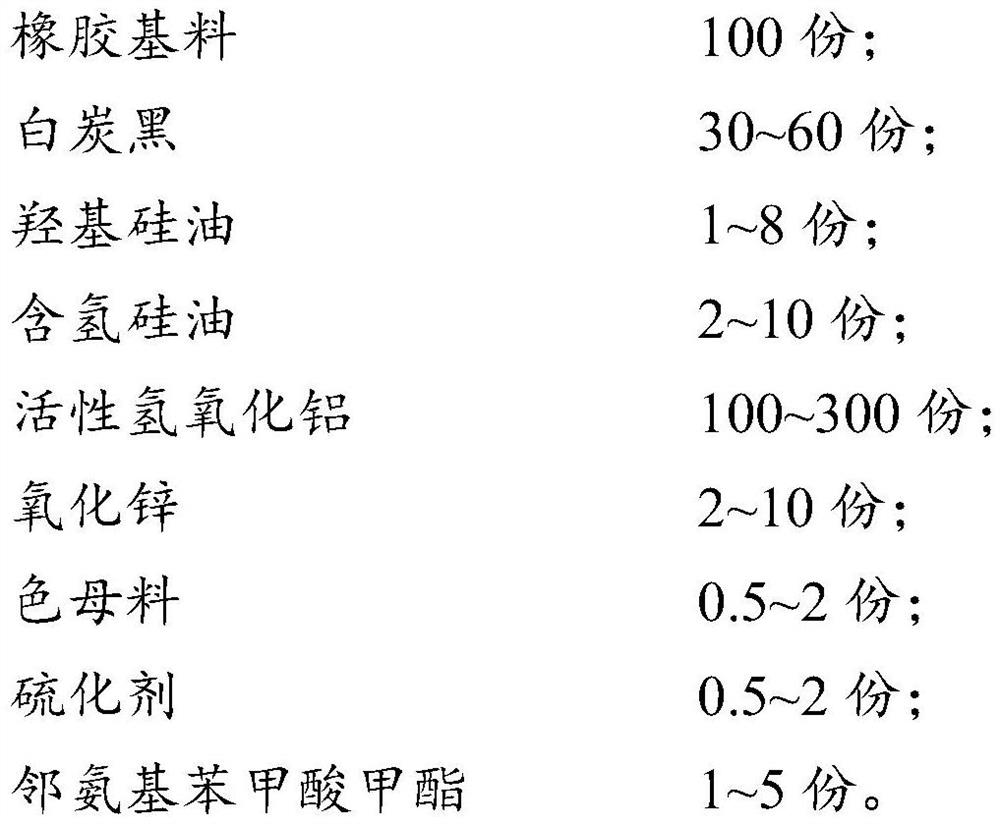

[0056] The silicone rubber material for composite insulators is prepared from raw materials containing the following parts by weight:

[0057]

[0058] Preparation of rubber base:

[0059] Mix the methyl vinyl silicone rubber with low vinyl content and the methyl vinyl silicone rubber with high vinyl content at a mass ratio of 1:2, the vinyl content of the methyl vinyl silicone rubber with low vinyl content is 0.07wt%, the vinyl content of the methyl vinyl silicone rubber with high vinyl content is 0.21wt%, the methyl vinyl silicone rubber with low vinyl content and the methyl vinyl silicone rubber with high vinyl content The weight average molecular weight of silicone rubber is 630,000.

[0060] Preparation methods include:

[0061] A) rubber base material, white carbon black, hydroxy silicone oil, hydrogen-containing silicone oil, active aluminum hydroxide, zinc oxide and methyl anthranilate are mixed into agglomerates to obtain a mixed rubber material; The temperature...

Embodiment 2

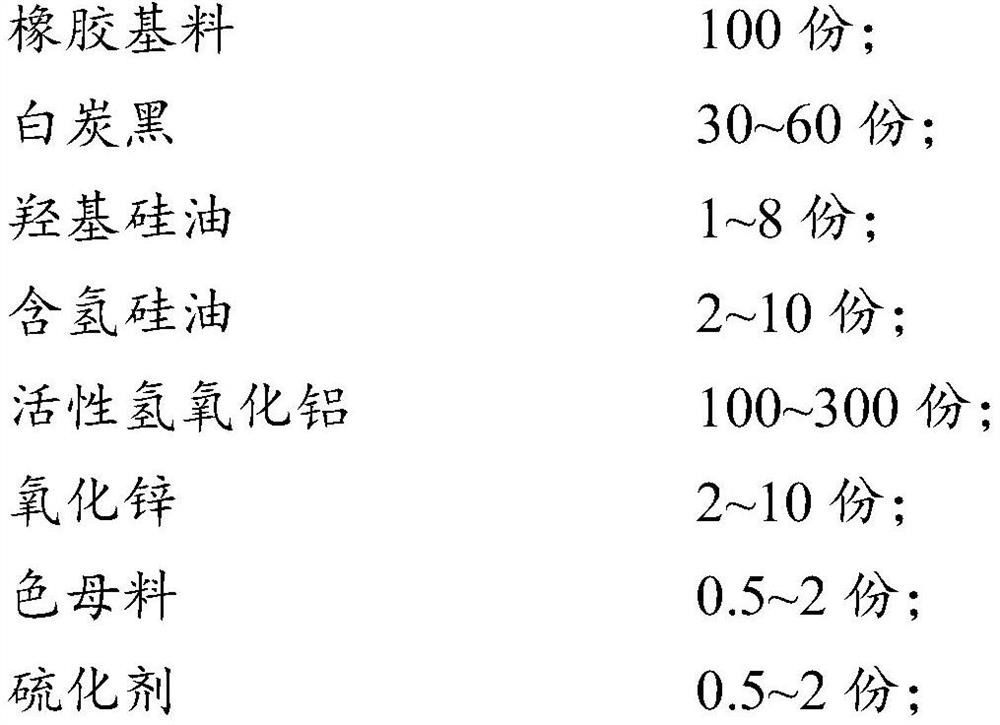

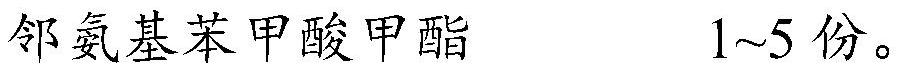

[0065] The silicone rubber material for composite insulators is prepared from raw materials containing the following parts by weight:

[0066]

[0067] Preparation of rubber base:

[0068] Mix the methyl vinyl silicone rubber with low vinyl content and the methyl vinyl silicone rubber with high vinyl content at a mass ratio of 1:2, the vinyl content of the methyl vinyl silicone rubber with low vinyl content is 0.08wt%, the vinyl content of the methyl vinyl silicone rubber with high vinyl content is 0.23wt%, the methyl vinyl silicone rubber with low vinyl content and the methyl vinyl silicone rubber with high vinyl content The weight average molecular weight of silicone rubber is 660,000.

[0069] Preparation methods include:

[0070] A) rubber base material, white carbon black, hydroxy silicone oil, hydrogen-containing silicone oil, active aluminum hydroxide, zinc oxide and methyl anthranilate are mixed into agglomerates to obtain a mixed rubber material; The temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com