3D printing composite material with CT imaging effect and preparation method and application thereof

A CT imaging and 3D printing technology, applied in the field of medical materials, can solve problems such as poor CT imaging effects, and achieve the effects of improving success rate, excellent CT imaging effects, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

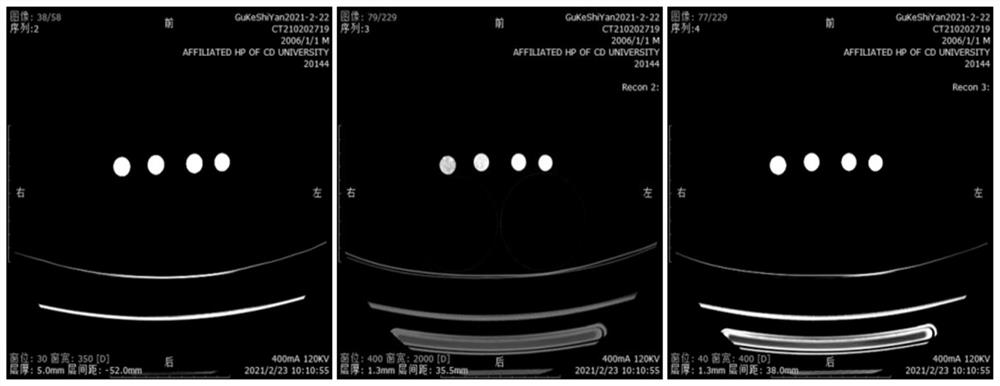

Image

Examples

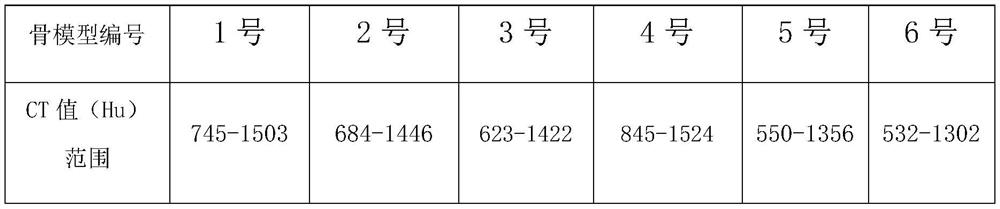

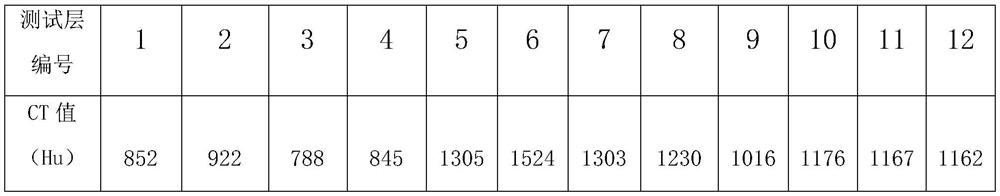

Embodiment 1

[0037] A 3D printing composite material with CT imaging effects, the composite material is composed of the following components in mass percentage:

[0038] Washable photosensitive resin 45wt%;

[0039] Polyacrylic acid 5wt%;

[0040] Nanoscale hydroxyapatite 45wt%;

[0041] Titanium dioxide 5wt%.

[0042] Put the above-mentioned 3D printing composite material with CT imaging effect into the planetary ball mill for ball milling to obtain the ball-milled slurry, set the speed of 300rmp ball milling time for 2h, first rotate forward for 30min and then reverse for 30min for 2 cycles. The slurry of No. 1 3D printing composite material was obtained by this preparation method.

Embodiment 2

[0044] A 3D printing composite material with CT imaging effects, the composite material is composed of the following components in mass percentage:

[0045] Washing photosensitive resin 50wt%;

[0046] Polyacrylic acid 5wt%;

[0047] Nanoscale hydroxyapatite 40wt%;

[0048] Titanium dioxide 5wt%.

[0049] According to the composition of the above components, according to the method for preparing a 3D printing composite material with CT imaging effect in Example 1, the slurry of No. 2 3D printing composite material was prepared.

Embodiment 3

[0051] A 3D printing composite material with CT imaging effects, the composite material is composed of the following components in mass percentage:

[0052] Washing photosensitive resin 55wt%;

[0053] Polyacrylic acid 5wt%;

[0054] Nanoscale hydroxyapatite 35wt%;

[0055] Titanium dioxide 5wt%.

[0056] According to the composition of the above components, according to the method for preparing a 3D printing composite material with CT imaging effects in Example 1, the slurry of No. 3 3D printing composite material was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com