Down pants zipper puller riveting mechanism

A technology of riveting mechanism and trousers zipper, applied in the direction of sliding fastener elements, applications, fasteners, etc., can solve the problems of the slider losing lock, difficult to reset, and the slider pull-up, etc., to increase the recovery force, structure Simple, improve the effect of self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

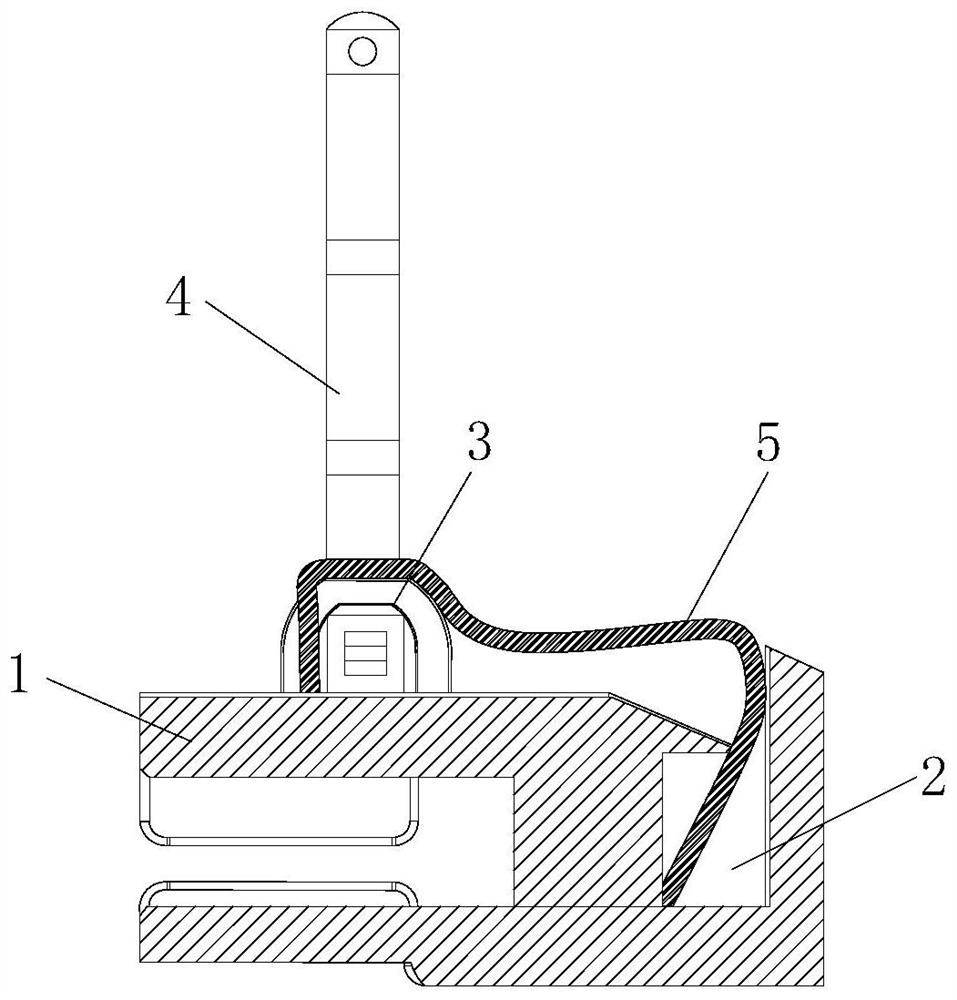

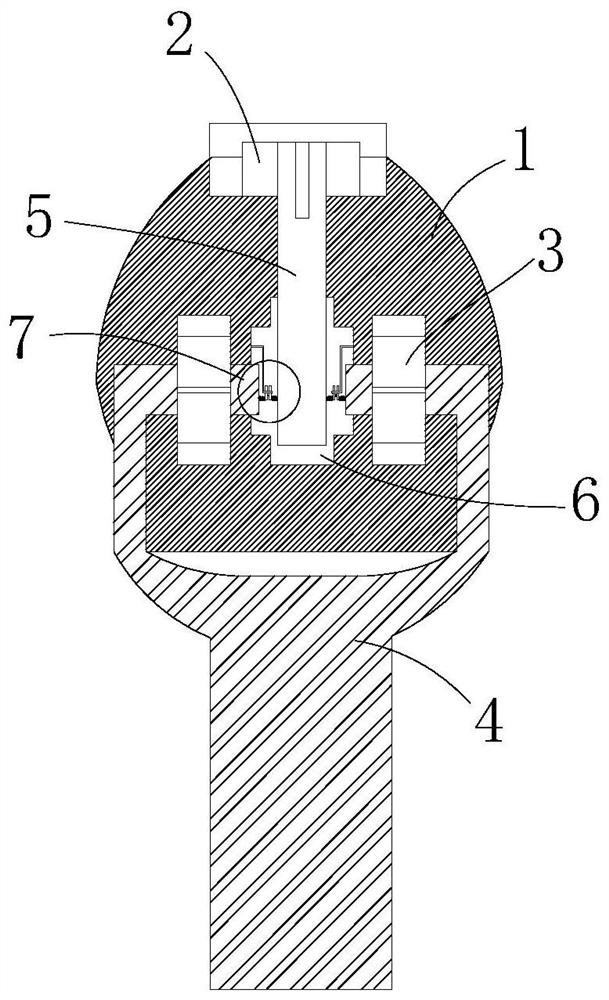

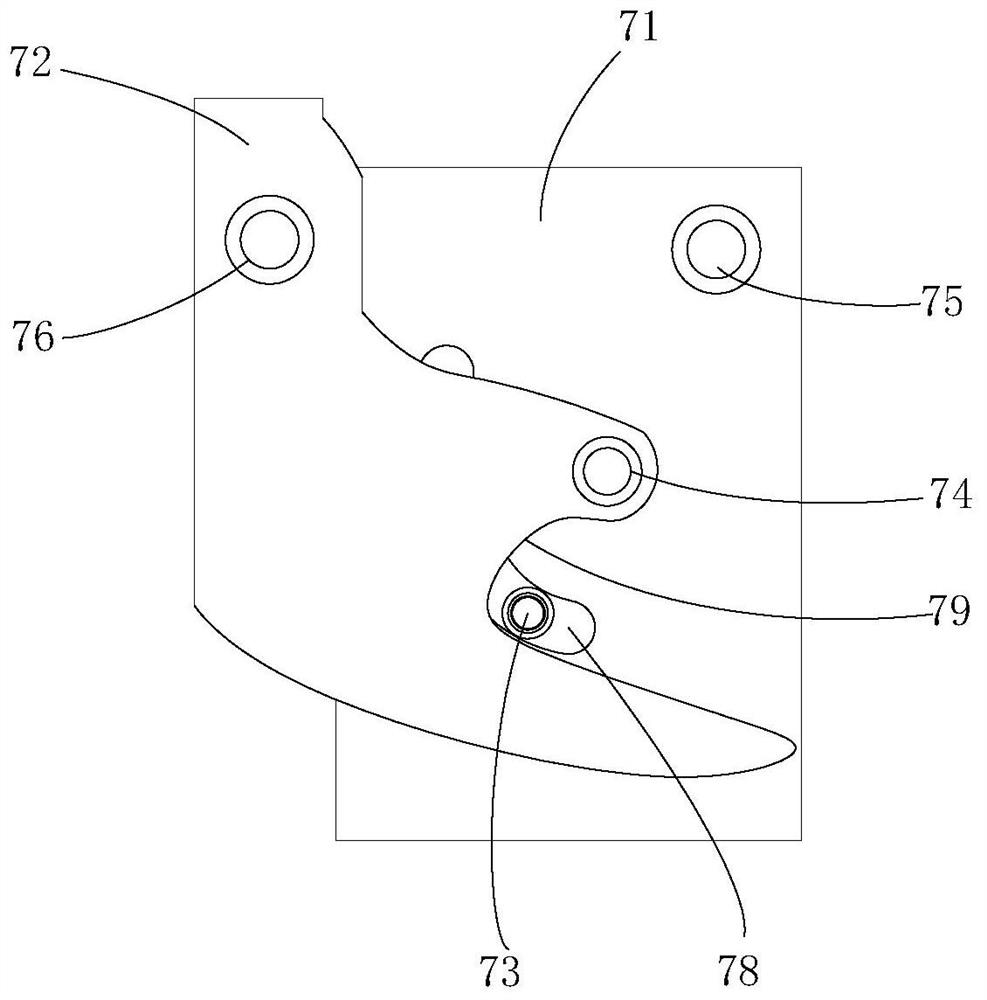

[0022] Such as Figure 1-4 As shown, a riveting mechanism for a zipper puller for down pants includes a slider body 1, a pull piece 4, and a shrapnel 5. The slider body 1 is riveted with the pull piece 4 through a riveting nose 3, and the upper end surface of the slider body 1 A shrapnel groove 2 and a self-locking groove 6 that cooperate with the locking of the shrapnel 5 are sequentially opened. The self-locking groove 6 is located below the riveting nose 3, and the riveting end of the pull piece 4 and the self-locking groove 6 are provided with a rebound self-locking mechanism 7 .

[0023] Through the pressure riveting of the pull piece 4 and the riveting nose 3, the pull piece 4 is movably set in the riveting nose 3. During the use of the slider, when the pull piece 4 rotates, the two ends of the shrapnel 5 respectively connect with the self-locking groove 6 It realizes self-locking and separation with the shrapnel groove 2, so as to avoid the existing problem that the pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com