Lifting platform

A lifting table and lifting frame technology, applied in the field of lifting table, can solve the problems of inability to meet the installation of the center pin of various models, difficulty in meeting the accuracy requirements of the center pin, and low degree of freedom in the installation of the center pin, so as to meet the needs of multi-degree-of-freedom adjustment. , The effect of high installation stability and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

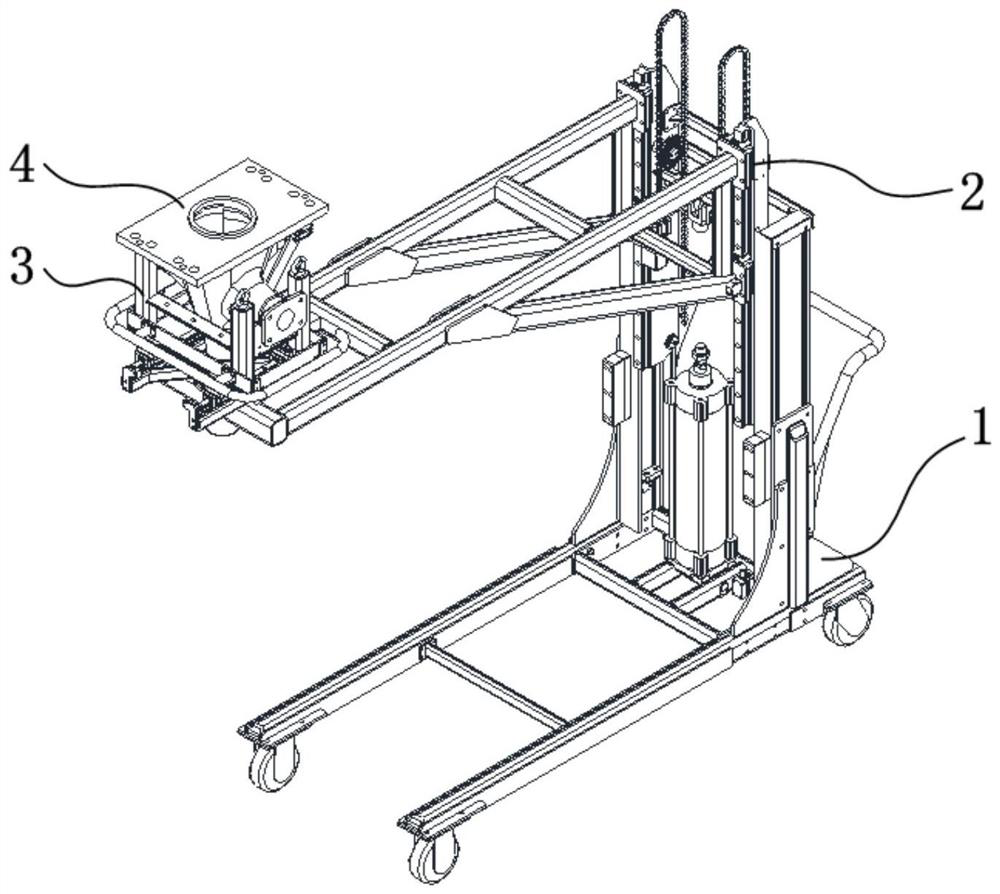

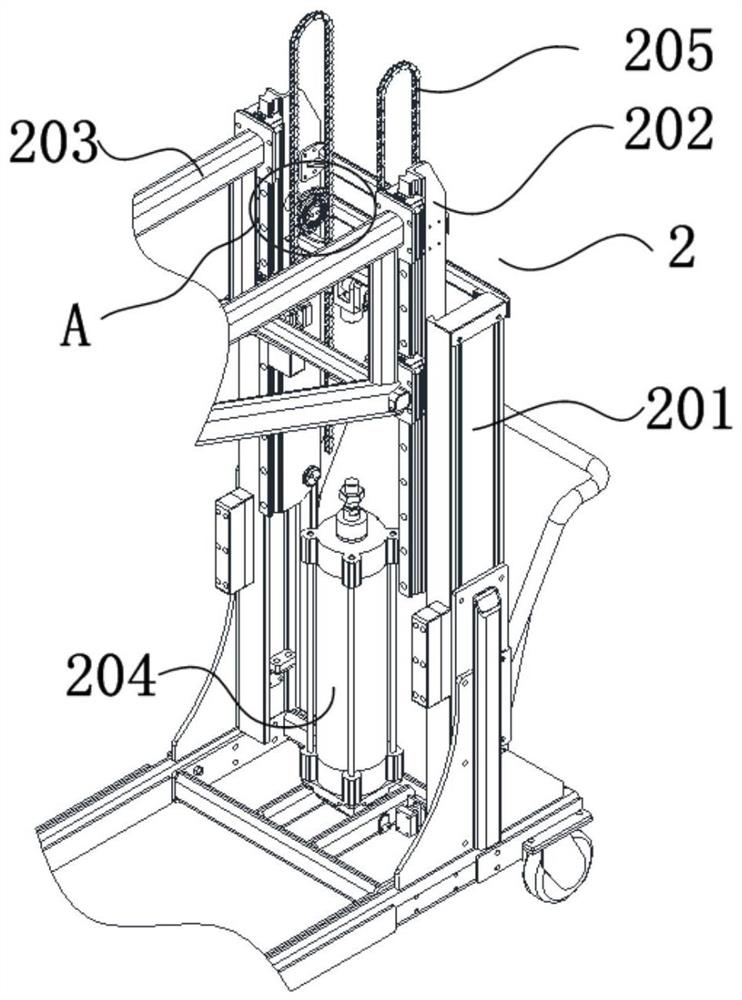

[0032] refer to Figure 1 to Figure 6 As shown, the present invention discloses a lifting platform, including: a machine base 1 , a moving module 2 and a loading assembly 3 .

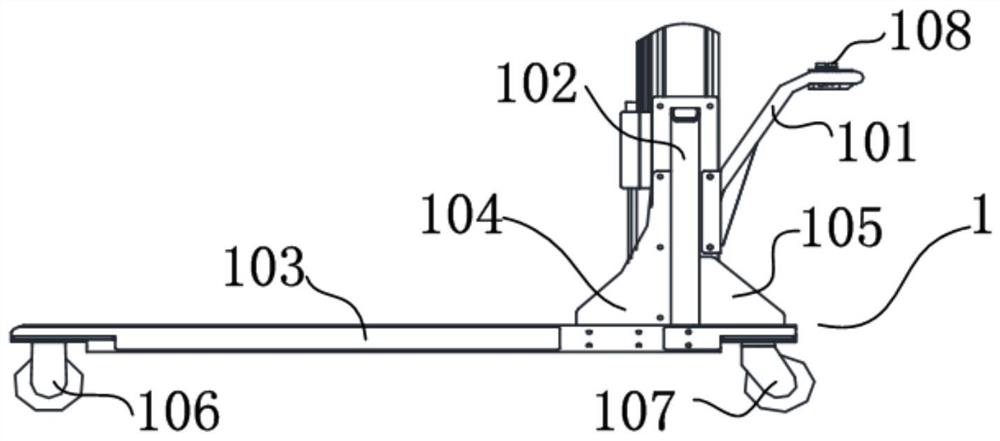

[0033] Above-mentioned machine base 1 comprises walking push rod 101, two symmetrical columns 102, main body frame 103, left rib 104, right rib 105, directional wheel 106, band brake universal wheel 107 and lift control button 108. Wherein, the walking push rod 101 is connected by bolts between two symmetrical columns 102 . The two symmetrical uprights 102 are welded and fixed to the main body frame 103 , and the left rib 104 and the right rib 105 are connected to the two symmetrical uprights 102 by bolts....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com