Continuous measurement method for crack length

A technology of crack length and measurement method, used in image data processing, instrument, character and pattern recognition, etc., can solve the cumbersome operation method of flexibility method, the test personnel cannot be liberated from mechanical operation, and the potential method is susceptible to current and The impact of the environment, etc., to achieve the effect of improving the measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The technical scheme that the present invention solves the problems of the technologies described above is as follows:

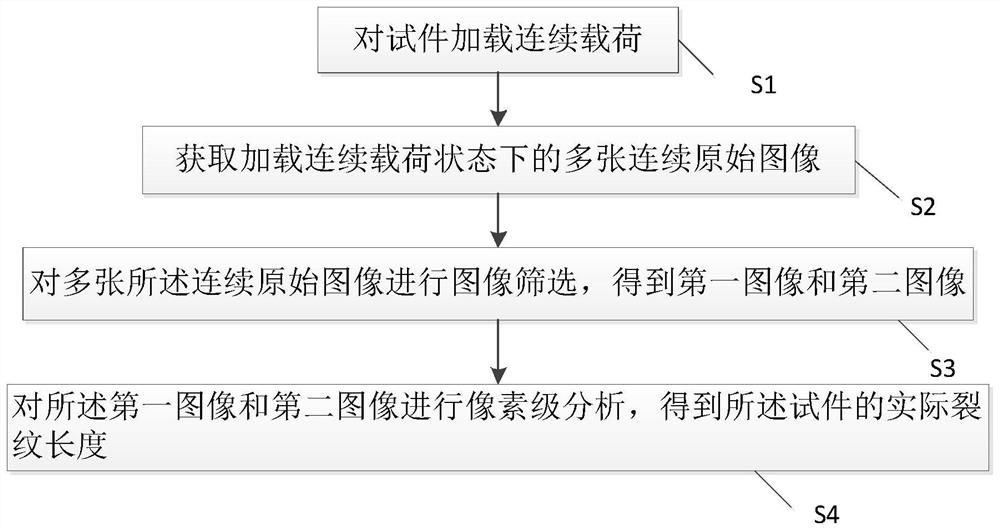

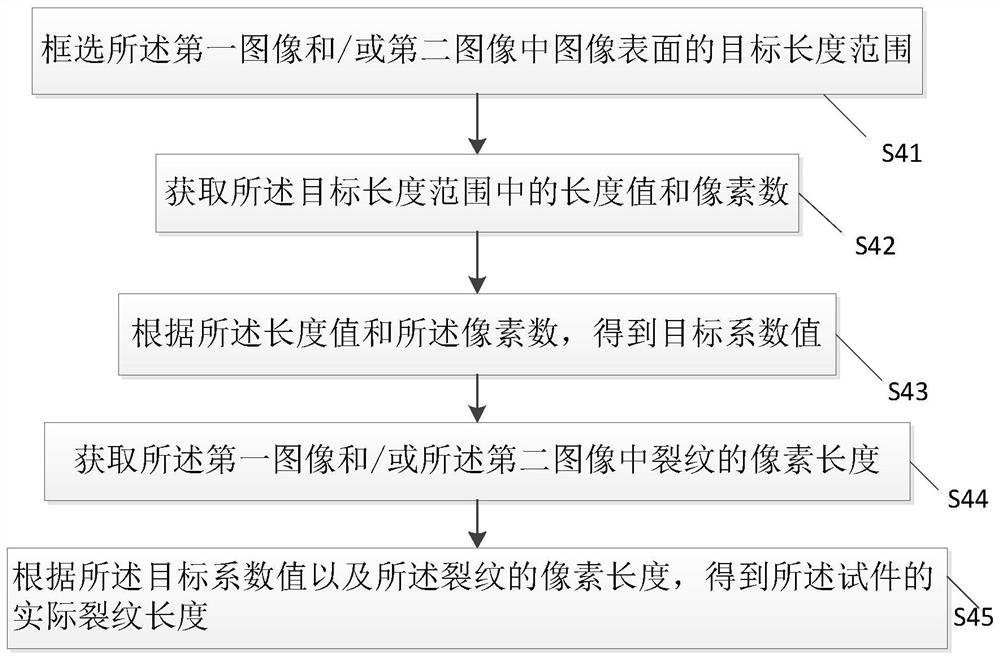

[0039] The invention provides a continuous measuring method of crack length, referring to figure 1 As shown, the continuous measurement method of the crack length includes:

[0040] S1: Continuous load is applied to the specimen;

[0041] S2: Obtain multiple continuous original images under continuous loading state;

[0042] Specifically, the speckle field is prepared on the surface of the test piece first, and then the multiple continuous original images are the captured images of the speckle field on the surface of the test piece. In addition, the operator can estimate the initial acquisition point where continuous original images need to be obtained during the process of loading continuous loads on the specimen, maintain the dynamic loading state, and operate at an operating frequency of 1 Hz. Until then, the operating frequency can be increased...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap