Variable-diameter rotor device and variable-pitch control method thereof

A technology of variable diameter and rotor, which is applied in the direction of rotorcraft, transportation and packaging, motor vehicles, etc., and can solve the problems of small overload, energy loss, and the length of helicopter blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

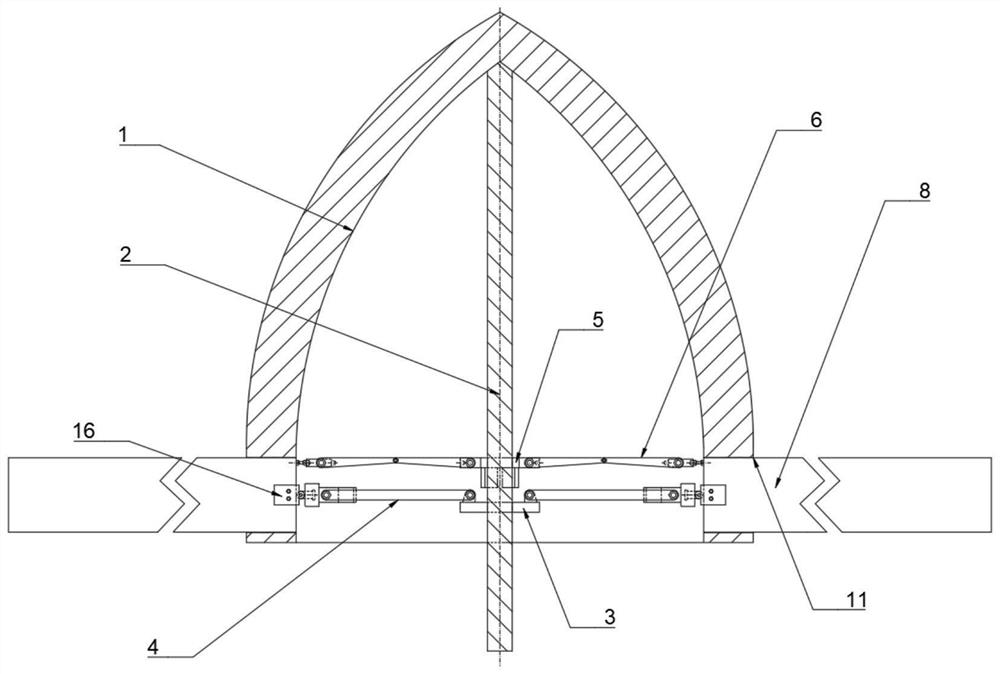

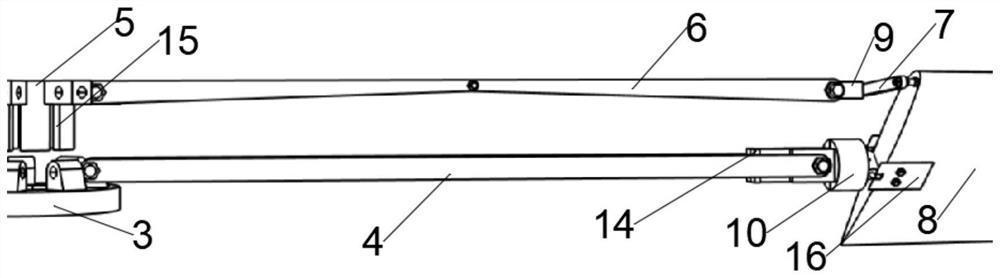

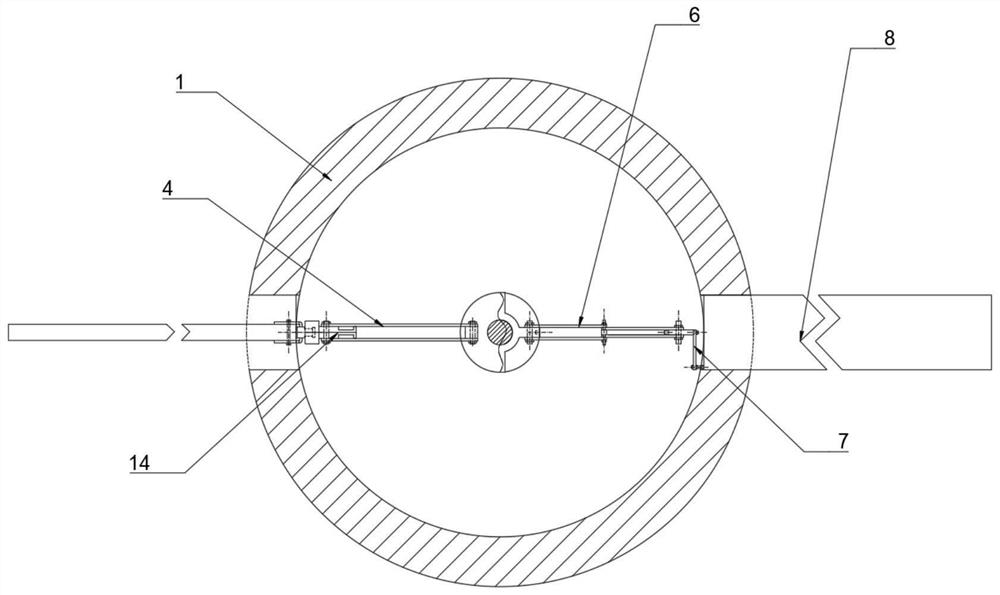

[0030] Overall structure of the present invention is as Figure 1-Figure 4 As shown, it includes a blade 8, a transmission mechanism, a blade contraction and extension structure, a blade pitch change structure and a retraction rod unloading structure.

[0031] The propeller contraction and extension structure includes a propeller hub 1, a central shaft 2, a shrink disc 3, a retractable rod 4 and a pitch change sleeve 10. There is a mounting hole 11 in the propeller hub 1, and the propeller hub 1 is fixedly connected with the center 2 shafts, and the shrink disc 3 is installed on the central shaft 2, and the transmission mechanism controls the shrink disc 3 to slide axially along the central shaft 2. The shrink disc 3 is connected to a pair of shrink rods 4 through a rotating hinge, and the other end of the shrink rod is connected to a paddle through a pitch-changing sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com