System and method for automatically detecting defects of large and small edges of packaging bag

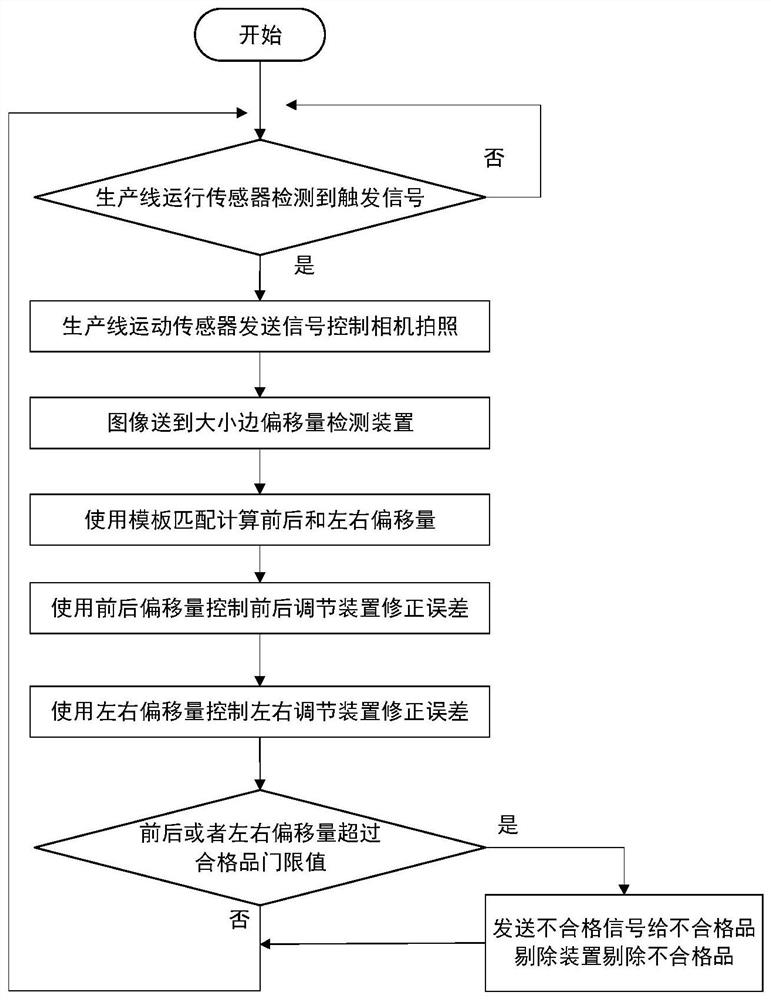

An automatic detection and packaging bag technology, which is applied in the directions of packaging, transportation and packaging, and optical testing for flaws/defects, etc. It can solve the problems of different edge widths of packaging bags, prone to missed inspections, false inspections, and low detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

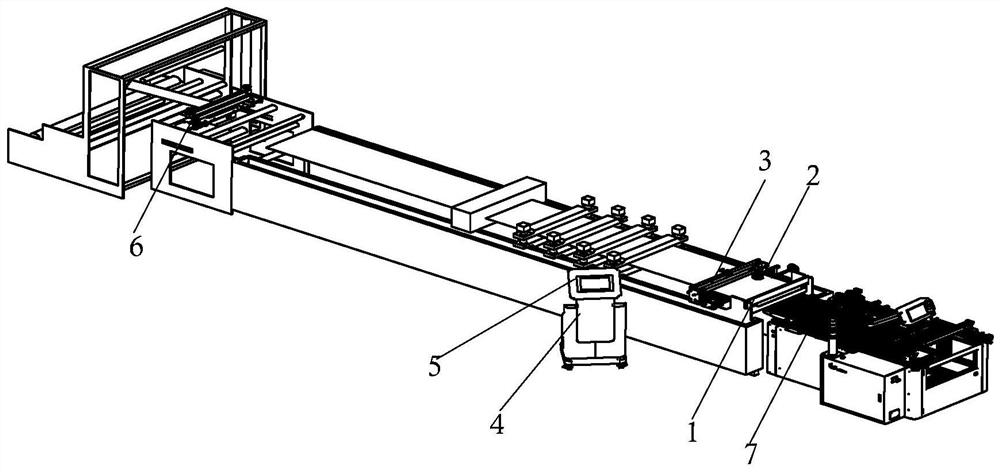

[0069] Such as figure 2 As shown, the automatic detection system for large and small side defects of packaging bags provided in this embodiment includes a trigger signal generating unit, a detection image acquisition unit, an installation device, a large and small side offset detection device, a detection result display device, a front and rear adjustment device, and a left and right adjustment device. device, rejecting device;

[0070] The cover defect detection device is arranged on one side of the frame, and is connected to the cover image acquisition unit by wire or wirelessly, the cover image acquisition unit is arranged on the frame through the installation device, and the trigger signal generation unit is arranged on the machine The position on the rack is suitable for judging the movement state of the packaging bag on the rack, the trigger signal generation unit sends the generated signal to the cover image acquisition unit; the cover defect detection device sends the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com