Electric vehicle thermal management system based on double heater

A thermal management system and technology for electric vehicles, applied in the field of thermal management systems for electric vehicles, can solve the problems of thermal management system controller impact, affecting service life, etc., and achieve the effects of extending power supply time, saving electric energy, and facilitating engagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

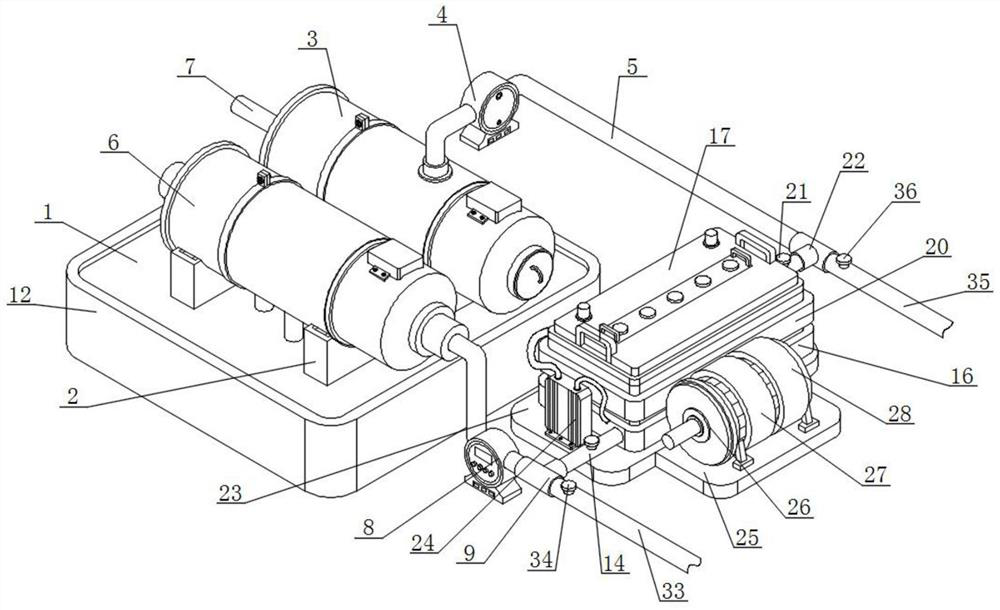

[0040] Such as figure 1 , Figure 5 and Figure 6 As shown, a thermal management system for electric vehicles based on dual heaters, including a plate 1, a fitting frame 2, a water heating heater 3, a water pump 4, and a water temperature output pipeline 5, and four sets of them are installed on the top of the plate 1 in a square arrangement. chimera box 2;

[0041] Specifically, the plate 1 provides sufficient space for the installation of the water heater 3 and the fuel heater 6, and the fitting frame 2 can facilitate the insertion of the fixed plate 12, and then facilitate the heating of the water heater 3 and the fuel oil welded with the fixed plate 12. The heater 6 is placed on the top of the fitting frame 2, and can effectively prevent the two sets of heaters from being out of contact with the fitting frame 2 during the running of the vehicle.

[0042] Among them, the tops of two groups of fitting frames 2 arranged in front and back are installed with plumbing heaters...

Embodiment 2

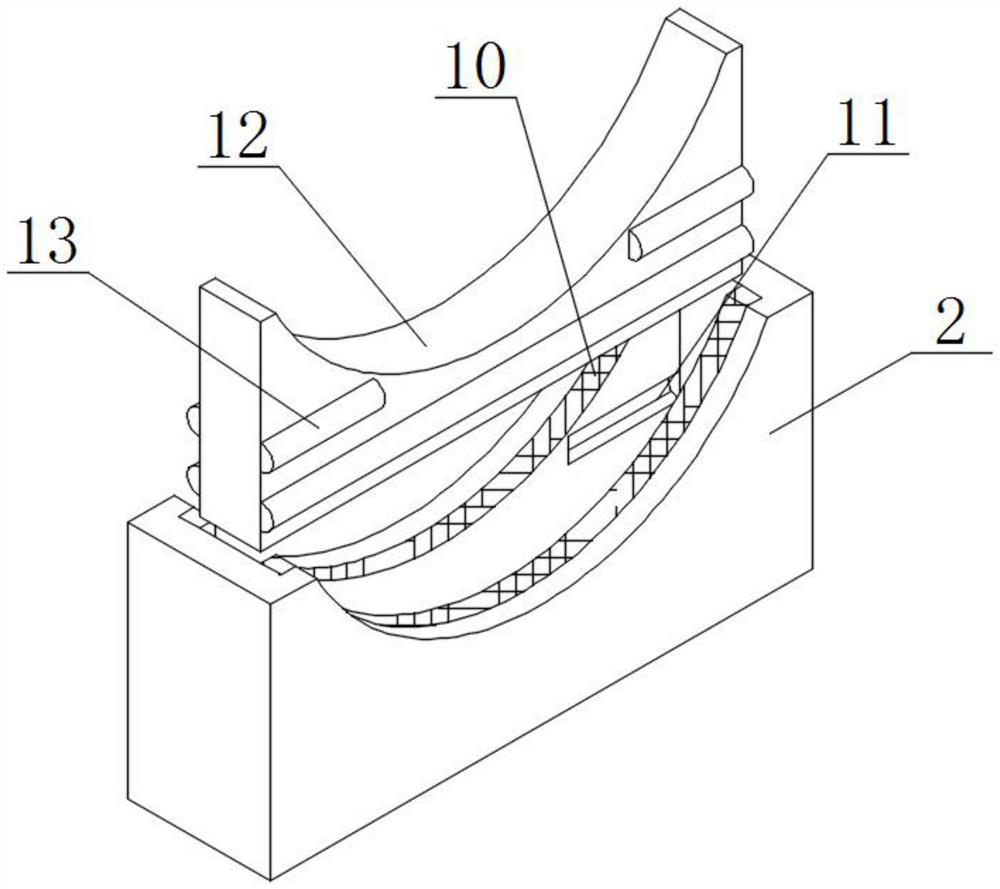

[0047] Such as figure 2 As shown, the inner wall of the fitting frame 2 is equipped with a rubber cushion frame 10, the outer wall of the rubber cushion frame 10 is provided with a groove 11, and the bottoms of the water heating heater 3 and the fuel heater 6 are equipped with two sets of fixing plates arranged in front and back. 12, and the front wall and rear wall of the fixed plate 12 are all attached to the inner wall of the rubber pad frame 10, the front and back of the fixed plate 12 are equipped with clips 13, and the outer wall of the clip 13 is attached to the inner wall of the groove 11 combine.

[0048] Specifically, the rubber cushion frame 10 has a certain degree of elasticity, and when it is squeezed, it can shrink inward to change its overall thickness. When the fixing plate 12 is inserted into the interior of the fitting frame 2, the rubber cushion frame 10 will be squeezed. Press inwardly to shrink to facilitate the engagement of the fixed plate 12. When the...

Embodiment 3

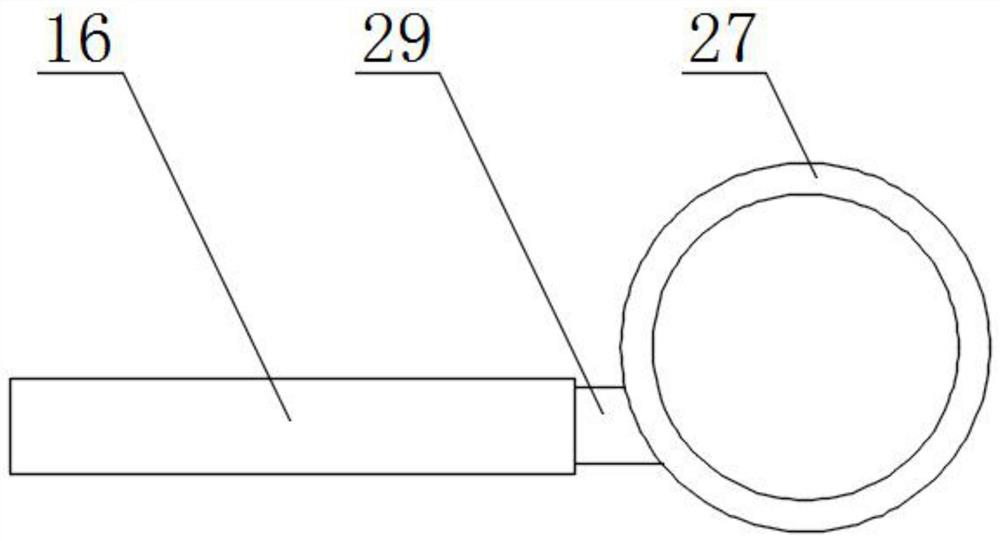

[0050] Such as figure 1 , image 3 , Figure 7 and Figure 8 As shown, a vent pipe 14 is installed on one side of the tee pipe 9, an electronic valve 15 is installed on the top of the vent pipe 14, and a battery vent return pipe 16 is installed at one end of the vent pipe 14, and the battery vent return pipe A battery box 17 is installed on the inner wall of the road 16, and the battery box 17 is located in front of the water heating heater 3.

[0051] The bottom wall of the battery box 17 is evenly equipped with multiple groups of battery blocks 18, the outer walls of both sides of the battery box 17 are equipped with temperature sensors 19, and the outer surface of the battery box 17 is equipped with a water temperature returning pipeline 20, and the water temperature returning pipeline 20 is located on the top of the battery ventilation return pipeline 16, a water guide pipe is installed on one side of the water temperature return pipeline 20, an electronic valve 2 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com