High-pressure oil pump top dead center position self-learning method, rail pressure control method, vehicle controller and vehicle

A self-learning method and vehicle controller technology, applied in the engine field, can solve the problem of inaccurate calculation of the real-time position of the top dead center of the oil pump, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

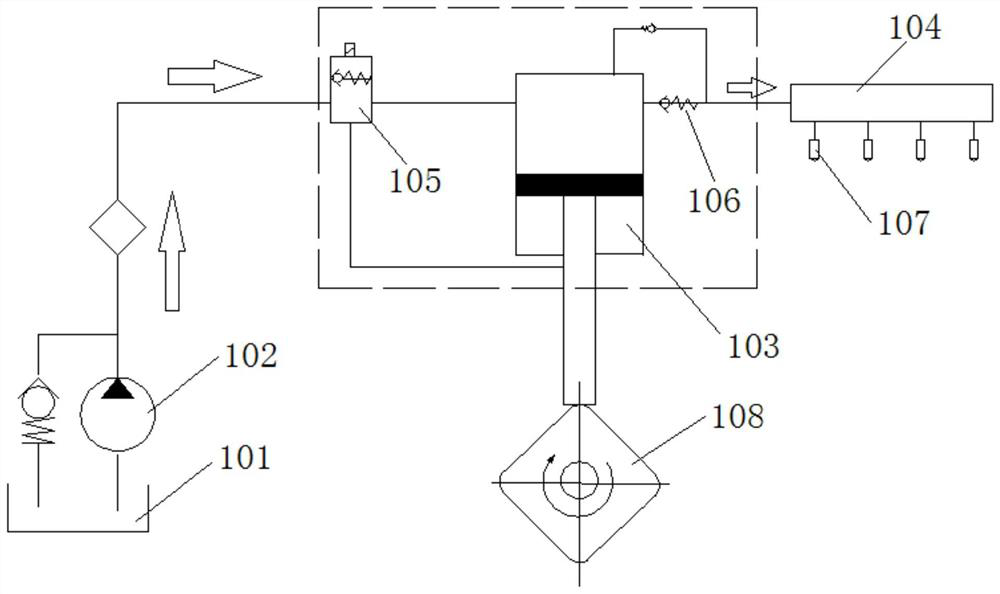

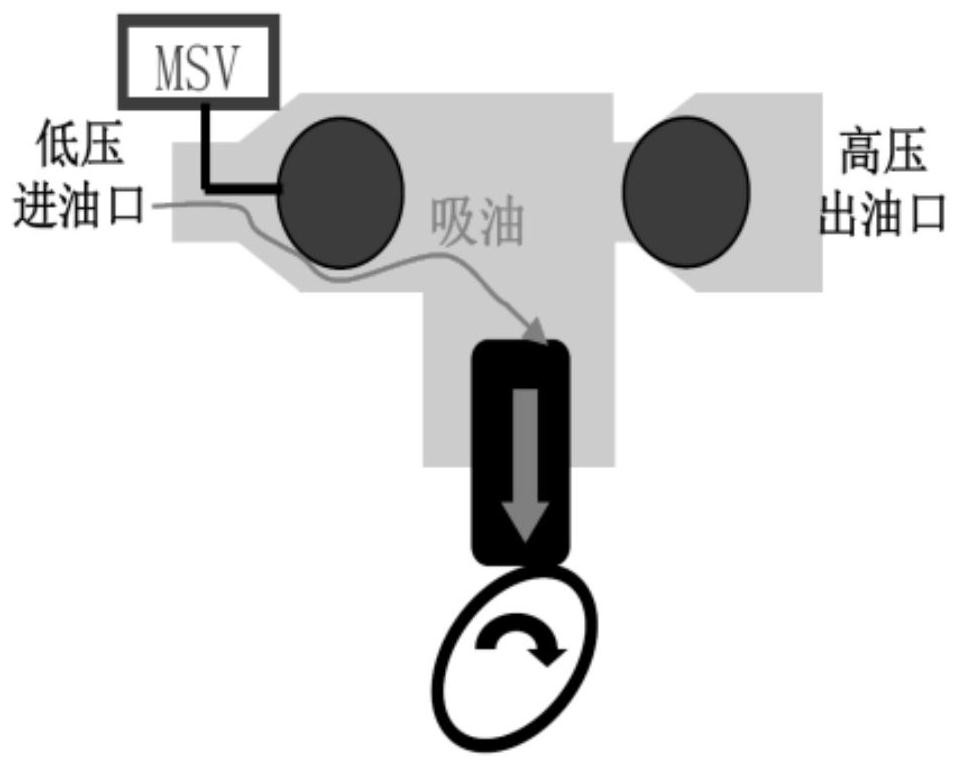

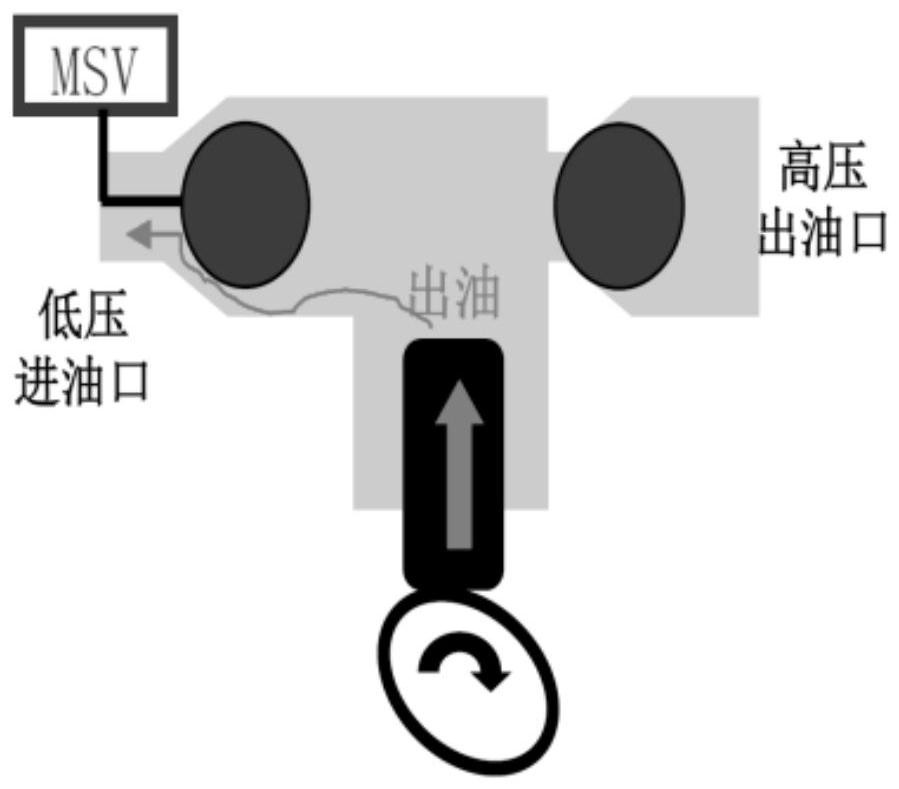

[0054] image 3 It is a schematic flow chart of the self-learning method for the top dead center position of the high-pressure oil pump in Embodiment 1 of the present invention. For the position and working principle of the high-pressure oil pump in the common rail system of the engine, please refer to figure 1 and Figure 2(a)-Figure 2(c) . from figure 1 It can be seen that the high-pressure oil pump 103 is arranged between the low-pressure oil circuit and the high-pressure oil circuit of the common rail system of the engine, and has a pressure regulating valve 105 that controls fuel to enter the high-pressure oil pump body through the low-pressure oil circuit. For the pressure regulating valve 105 , the MSV valve is used as an example below.

[0055] Figure 4 It is a schematic diagram of the principle of an example of self-learning the top dead center position of the high-pressure oil pump in the embodiment of the present invention, which is the same as Figure 1-Figur...

Embodiment 2

[0086] Image 6 It is a schematic flowchart of a method for controlling rail pressure of a high-pressure oil pump according to Embodiment 2 of the present invention. like Image 6 As shown, the high-pressure oil pump rail pressure control method may include the following steps:

[0087] In step S610, the top dead center position of the high pressure oil pump is determined using the above-mentioned self-learning method for the top dead center position of the high pressure oil pump.

[0088] Here, for the specific implementation details of step S610, reference may be made to Embodiment 1, which will not be repeated here.

[0089] Step S620, based on the determined top dead center position of the high-pressure oil pump, determine the closing time and closing duration of the pressure regulating valve.

[0090] Referring to Figure 2(c) and figure 1 , when the MSV valve is closed, the connection between the high-pressure oil pump 103 and the low-pressure oil circuit is cut off, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com