Method for measuring displacement of oscillating piston

A piston displacement and measurement method technology, which is applied in measuring devices, radio wave measurement systems, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as the inability to directly measure piston displacement, the inability to install sensors, and the inability to directly measure piston displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

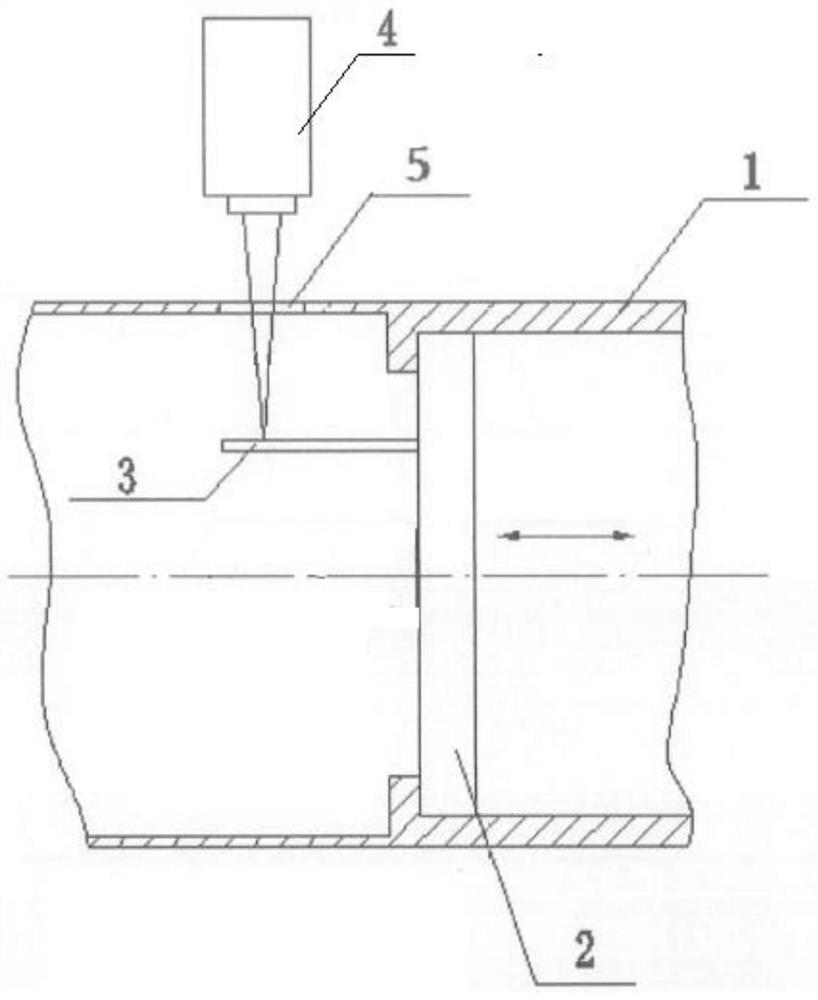

[0020] The purpose of this embodiment is to propose a method for measuring the displacement of the oscillating piston, especially to provide a method for measuring the displacement of the high-frequency oscillating piston in the test of the aeroengine components without causing major damage to the casing.

[0021] A method for measuring the displacement of an oscillating piston. Holes are opened in the non-working area of the casing 1 perpendicular to the axial direction. After the holes are opened, light-transmitting glass 5 is filled in the gaps and sealed with sealant to ensure the tightness of the casing. Generally speaking, on the wall surface of the casing 1 apart from the working position of the piston 2 by 15 centimeters, a hole with a diameter of 4 cm is opened perpendicular to its axial direction.

[0022] On the non-working surface of the piston 2, use silica gel to fix the piston displacement lead-out part 3 perpendicular to the surface of the piston 2, and the pi...

Embodiment 2

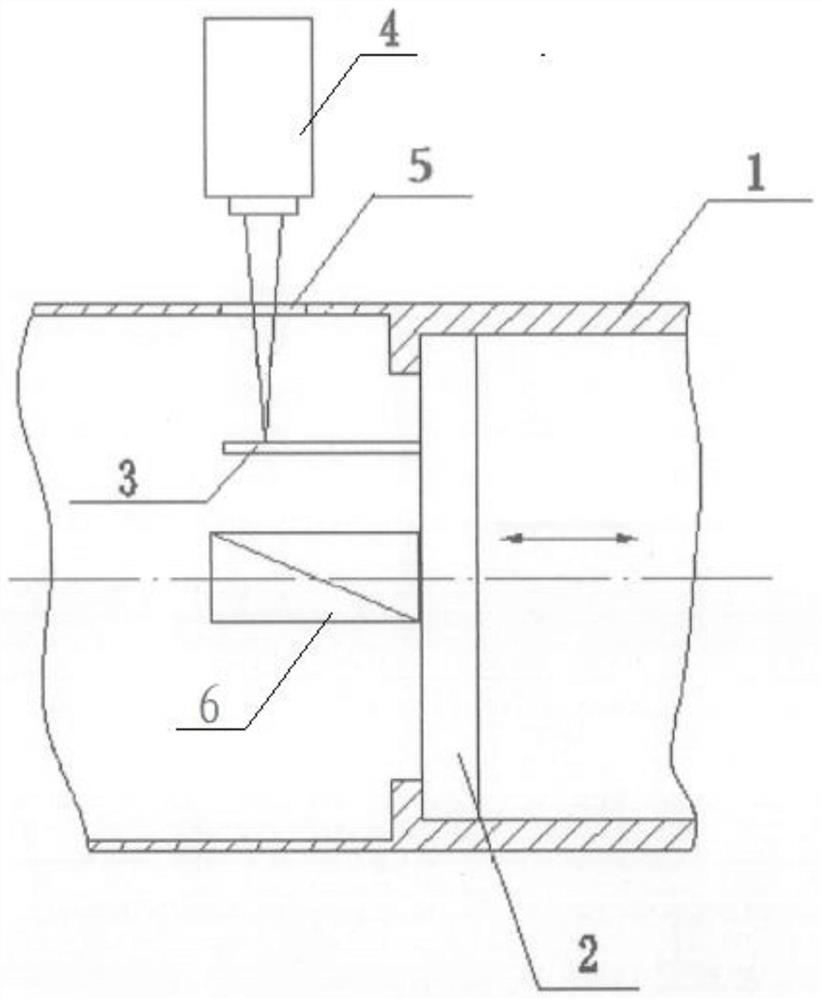

[0030] This example figure 2 As shown, the piston 2 is driven by the electromagnet 6, and the laser beam emitted by the laser vibrometer 4 is irradiated on the piston outlet 3 through the transparent glass 5. By testing the displacement of the piston outlet 3, the oscillation displacement of the piston 2 can be obtained. quantity.

[0031] The remaining implementation methods and expected effects are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com