A suction force device for automatic testing of electromagnetic brakes in complex application environments

A technology of electromagnetic brake and application environment, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems of limited testing environment, smaller braking torque of electromagnetic brakes, and overall performance of electromechanical actuators. To achieve the effect of broadening the test environment, improving accuracy and precision, and measuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

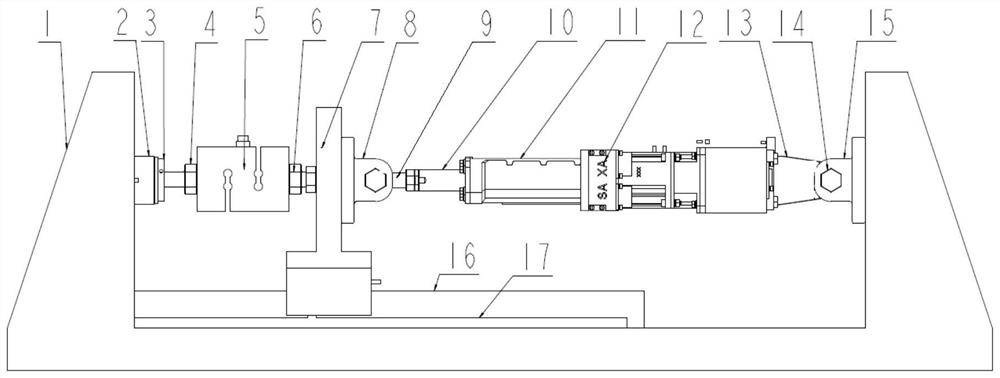

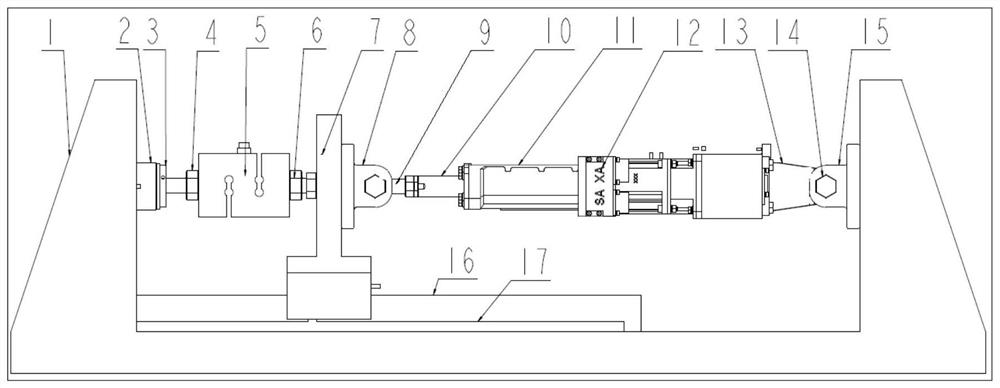

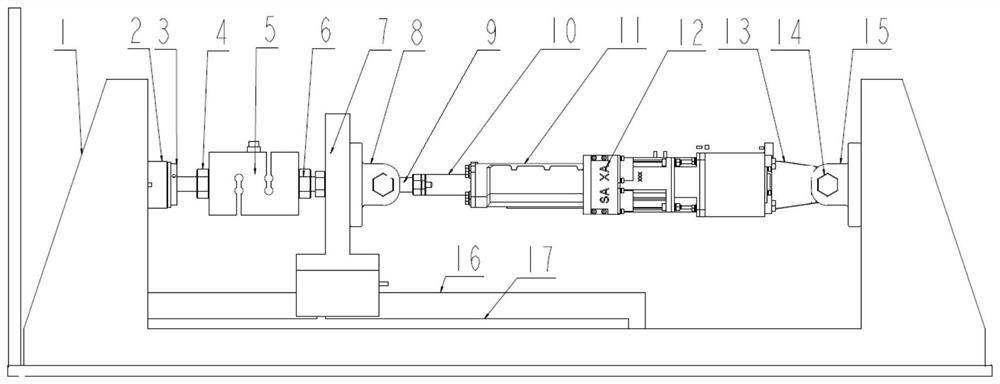

[0033] The present invention proposes a suction force device for automatically testing electromagnetic brakes in a complex application environment, including a base 1, a brake connecting shaft 4, a tension pressure sensor 5, a tension pressure sensor connection shaft 6, a sliding plate 7, and front lugs Seat 8, electromechanical actuator, rear lug support 15, guide rail 16, grating ruler 17.

[0034] The base 1 has a U-shaped structure, and the electromagnetic brake stator 2 is fixed at the "|"-shaped structure on one side of the base 1. The electromagnetic brake mover 3 is connected to the pull-pressure sensor 5 through the brake connection shaft 4, and the pull-pressure sensor 5 passes the pressure The sensor connecting shaft 6 is fixed on one side of the sliding plate 7, the other side of the sliding plate 7 is installed with the front lug support 8, and the rear lug support 15 is installed at the “|” type structure on the other side of the base 1, the electromechanical The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com