A device for testing the toughness standard of aluminum-plastic plate core material

An aluminum-plastic panel and core material technology, which is applied in the measurement device, using a single impact force to test the strength of the material, and using a stable bending force to test the strength of the material, etc. The overall detection process is cumbersome and the effect of data recording is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

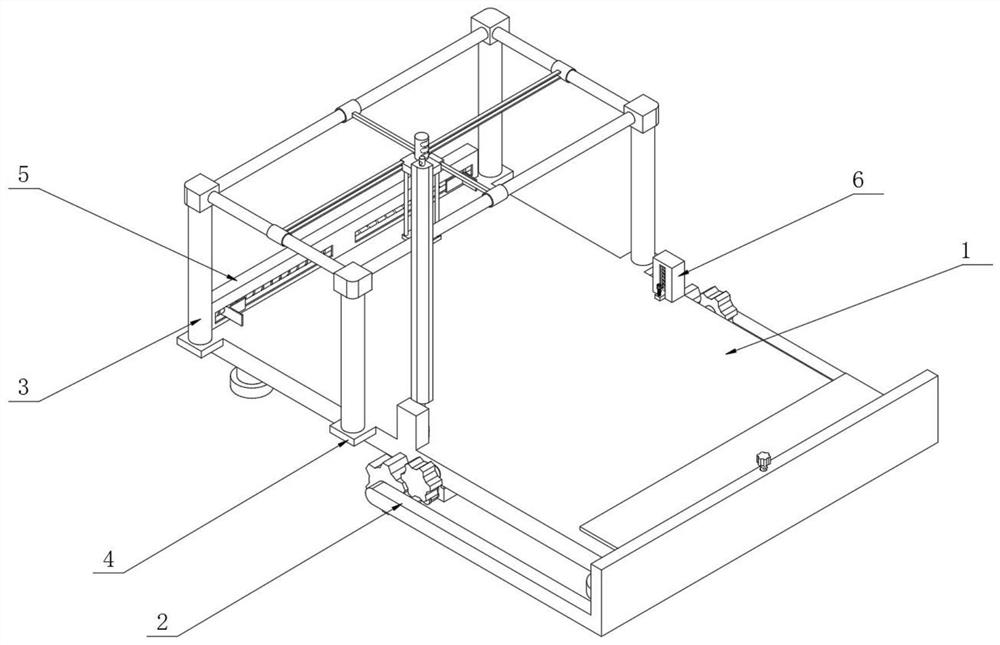

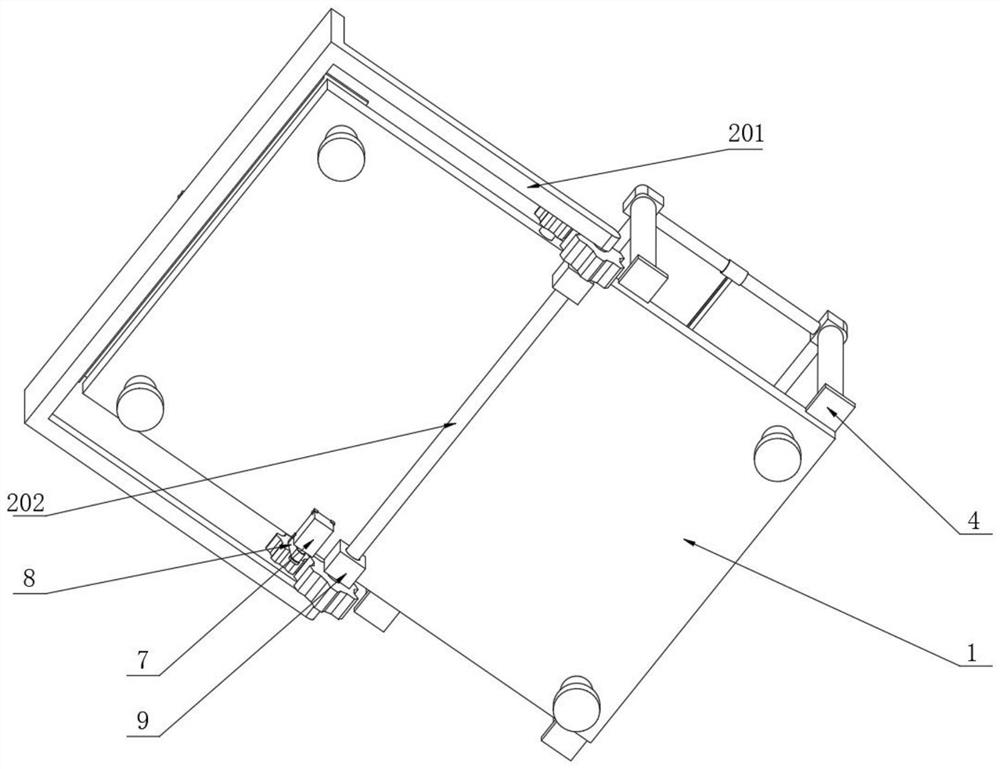

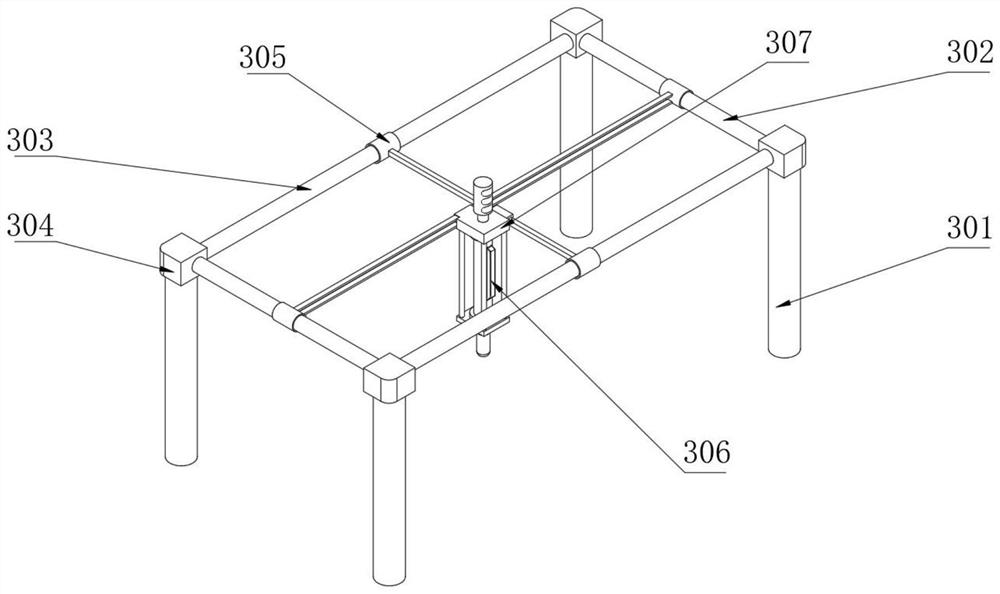

[0036] like Figure 1-11 As shown in the figure, a device for detecting the toughness standard of the core material of an aluminum-plastic board includes an operation table 1, a middle mounting seat 6 is integrally provided on both sides of the middle part of the upper surface of the operation table 1, and both sides of the middle part of the lower surface of the operation table 1 are integrated respectively. A rotating rod mounting sleeve 9 is provided, a plurality of expansion mounting plates 4 are integrally provided on one side edge of the console 1, and a matching through hole 10 is formed through the console 1 on the side away from the expansion mounting plate 4. The matching through hole 10 and the rotating A bending component 2 is installed inside the rod mounting sleeve 9, a single-side limit bar 5 is fixedly installed on the upper surface of the console 1 on one side of the expansion installation plate 4, and an impact component 3 is fixedly installed on the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com