Vamp pressing mechanism for processing sports shoes

A pressing mechanism and technology for sports shoes, which is applied in the direction of footwear, shoemaking machinery, applications, etc., can solve the problems of mesh position deviation, mesh falling, etc., and achieve the effect of preventing indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

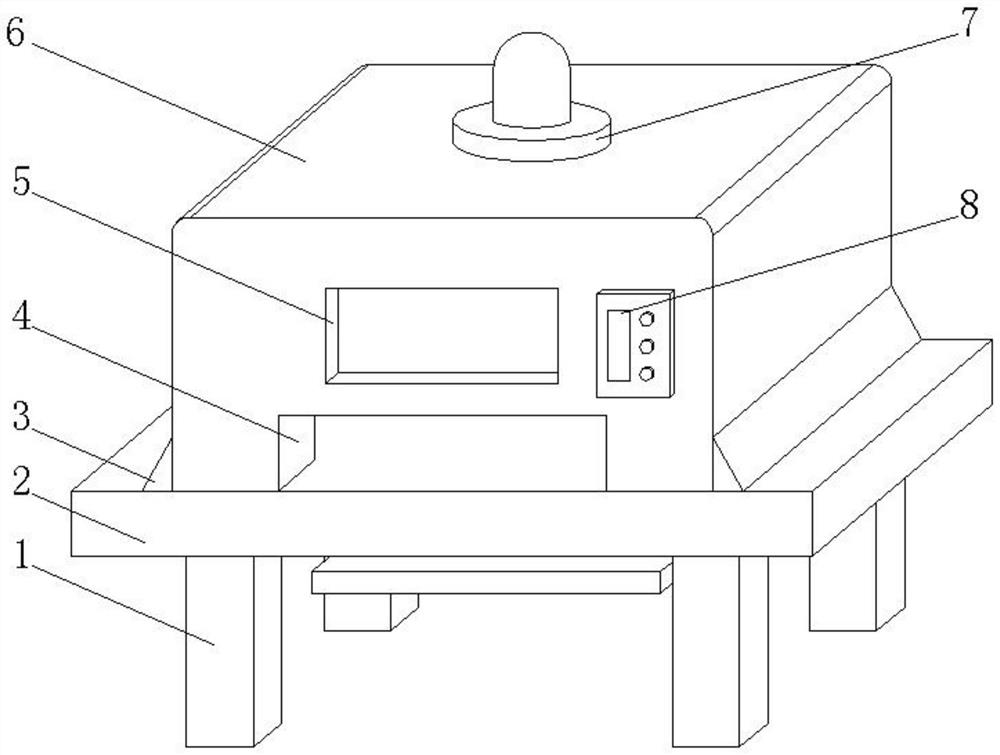

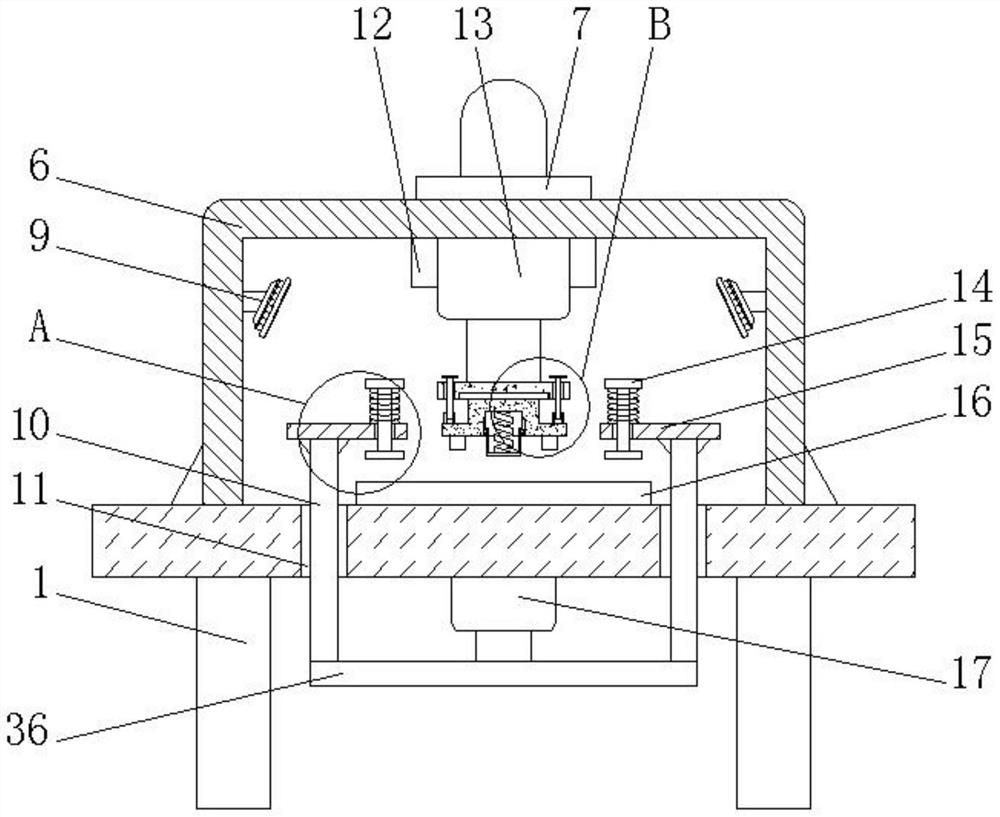

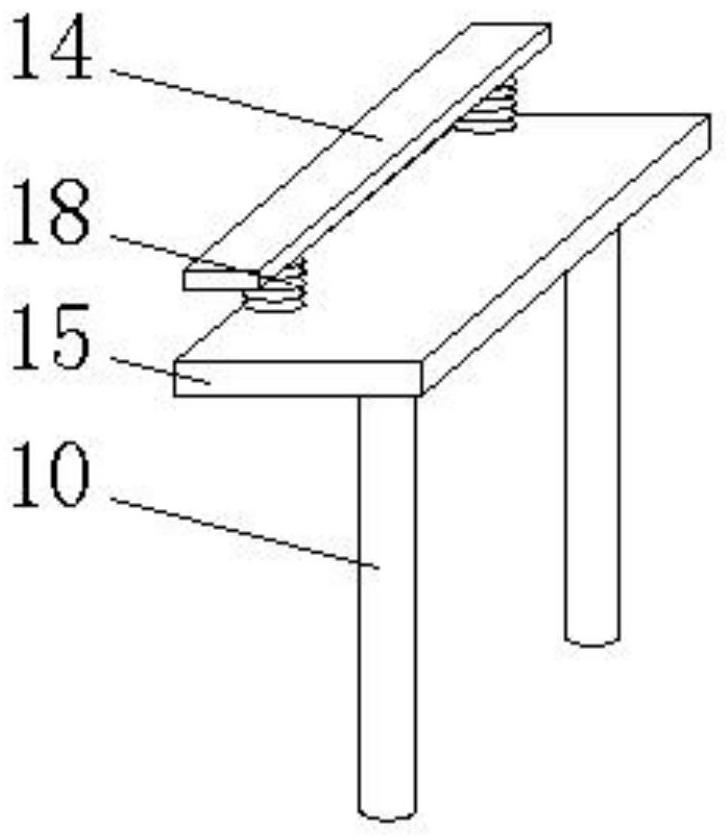

[0028] see Figure 1-7 , in this embodiment: a shoe upper pressing mechanism for sports footwear processing, including a carrier plate 2, the upper surface of the carrier plate 2 is fixedly connected with a housing 6, the front of the housing 6 is provided with a port 4, and the carrier plate The upper surface of the housing 6 is fixedly connected with a stage 16, the inner top wall of the housing 6 is fixedly connected with a hydraulic rod 13, the telescopic end of the hydraulic rod 13 is fixedly connected with a connecting plate 24, and the inner ring of the connecting plate 24 is fixedly connected with a pressure bearing 23 , the inner ring of the pressure bearing 23 is fixedly connected with a connection block 35, the bottom surface of the connection block 35 is fixedly connected with two pressure bars 30, the bottom surface of the connection block 35 is provided with a groove 25, and the inner top wall of the groove 25 is fixedly connected with a spring 26 , the bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com