Positioning tool based on mechanical part machining

A technology of mechanical parts and positioning tooling, which is applied in the field of mechanical parts, can solve problems such as rotation and sliding of circular mechanical parts, different sizes of mechanical parts, and positioning devices that cannot be adjusted, so as to increase friction and fixity, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

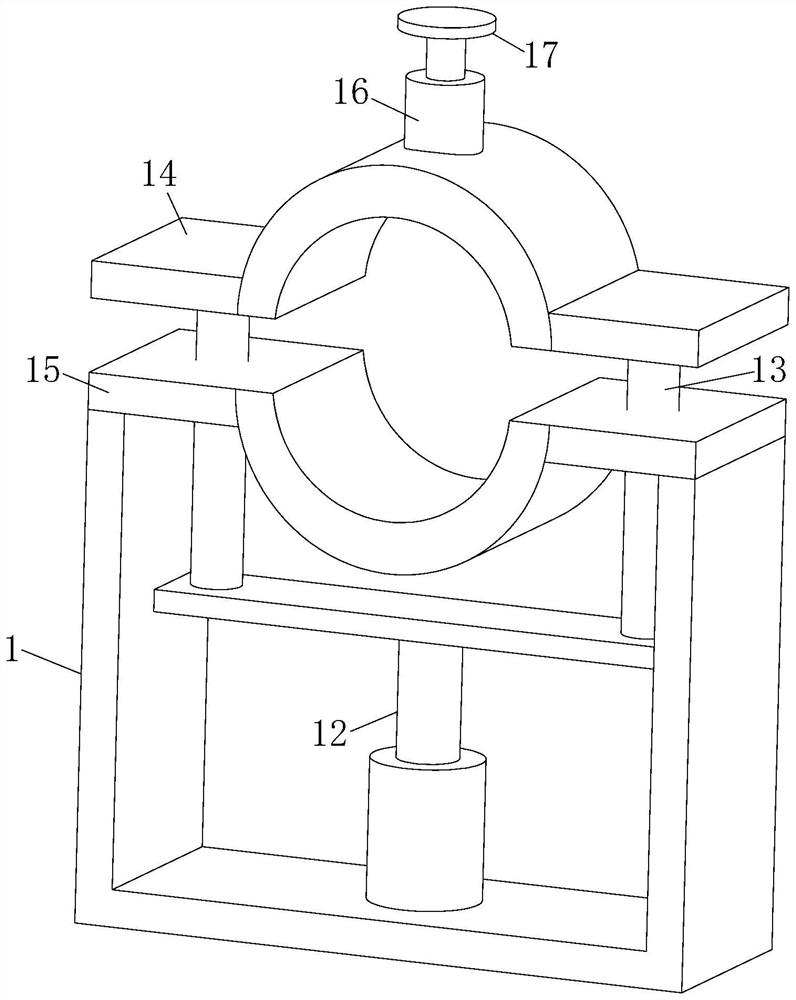

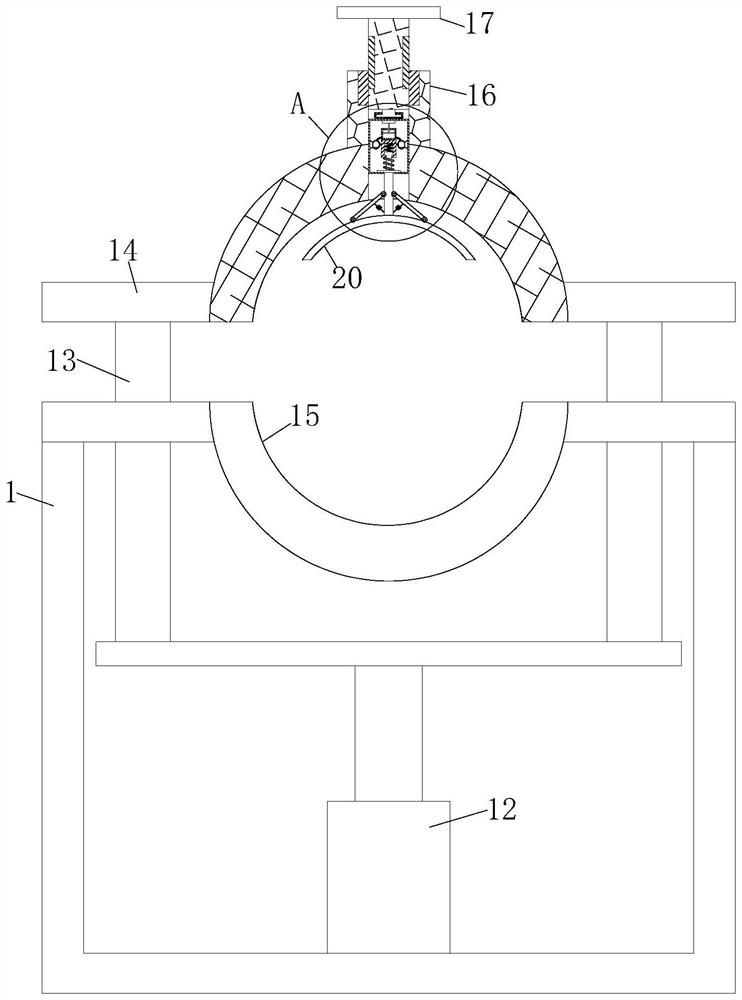

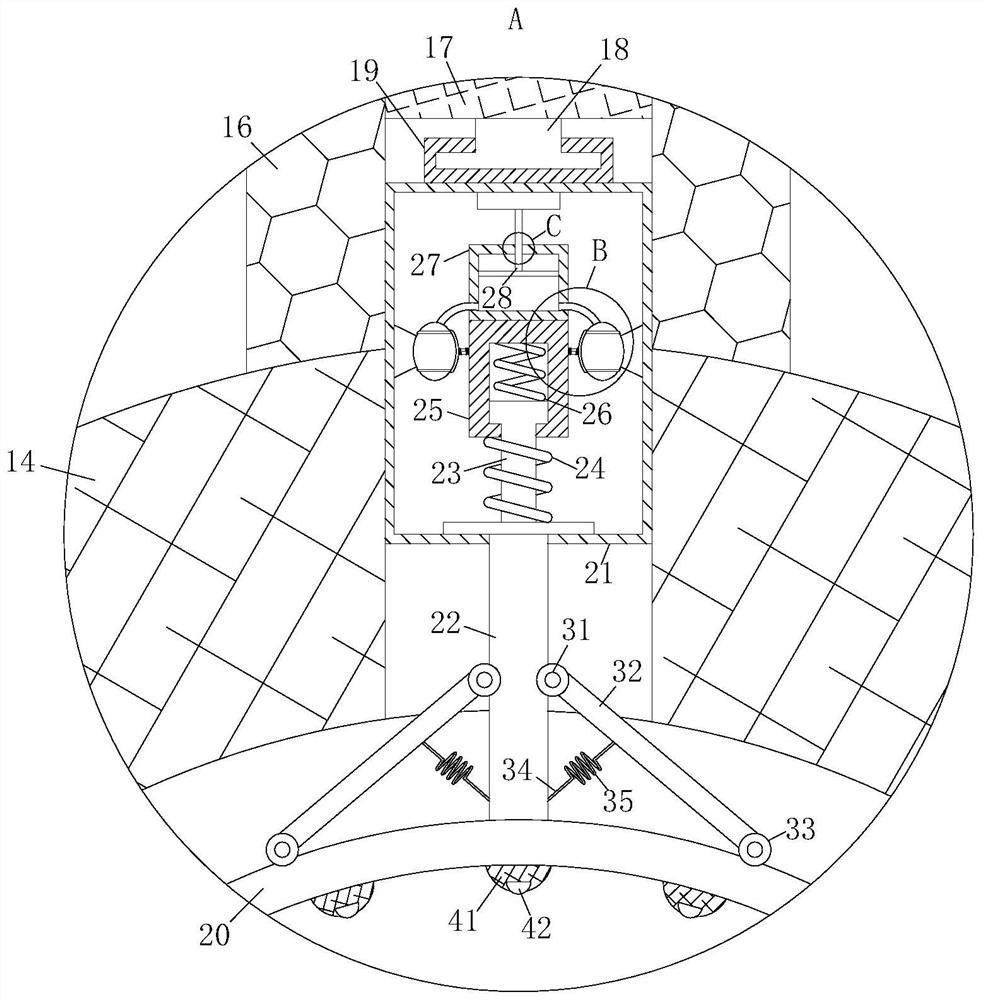

[0028] see Figure 1-5 As shown, based on the positioning tool for processing mechanical parts, it includes a board body 1; an electric push rod 12 is fixedly connected to the board body 1; a slide bar 13 is fixedly connected to the top end of the electric push rod 12; the slide bar No. 1 splint 14 is affixed to the top of 13; No. 2 splint 15 is affixed to the top of the plate body 1; Retention sleeve 16 is affixed to the middle of the No. 1 plywood 14; Rotation connection on the retention sleeve 16 There is an adjusting rod 17; the bottom end of the adjusting rod 17 is fixedly connected with a rotating rod 18; the rotating rod 18 is provided with a retaining shell 19; the bottom end of the retaining shell 19 is fixedly connected with a housing 21; The housing 21 is slidably connected with a push rod 22; the bottom end of the push rod 22 is affixed with a fixed pressure plate 20; the top end of the push rod 22 is affixed with an extruding rod 23; the extruding rod No. 1 elast...

Embodiment 2

[0037] see Figure 6 As shown in Comparative Example 1, as another embodiment of the present invention, the oil scraper 46 is affixed to the top of the oil absorbing plate 40; during operation, the oil in the oil tank 38 is coated on the side of the pusher plate 28 At the wall, the oil will slide with the sliding of the pusher plate 28, and the inside of the oil scraper 46 is provided with a scraper, and the oil on the pusher plate 28 can be scraped off by the oil scraper 46, so as to avoid a large amount of oil The air plate 28 slides, causing oil to leak at the side wall between the air cylinder member 27 and the pusher plate 28 .

[0038] Working principle: When working, place the circular mechanical parts to be processed on the No. 2 splint 15, start the electric push rod 12 to make the slider 13 slide down, and the sliding of the slider 13 will make the No. 1 splint 14 slide down first. , cooperate with No. 2 splint 15 to fix the circular mechanical parts. If the volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com