Safety protection device for internal maintenance of elevator and implementation method thereof

A safety protection device and elevator technology, which is applied in the direction of ladders, transportation and packaging, construction, etc., can solve the problems of increased danger, low safety performance of herringbone ladders, shaking, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

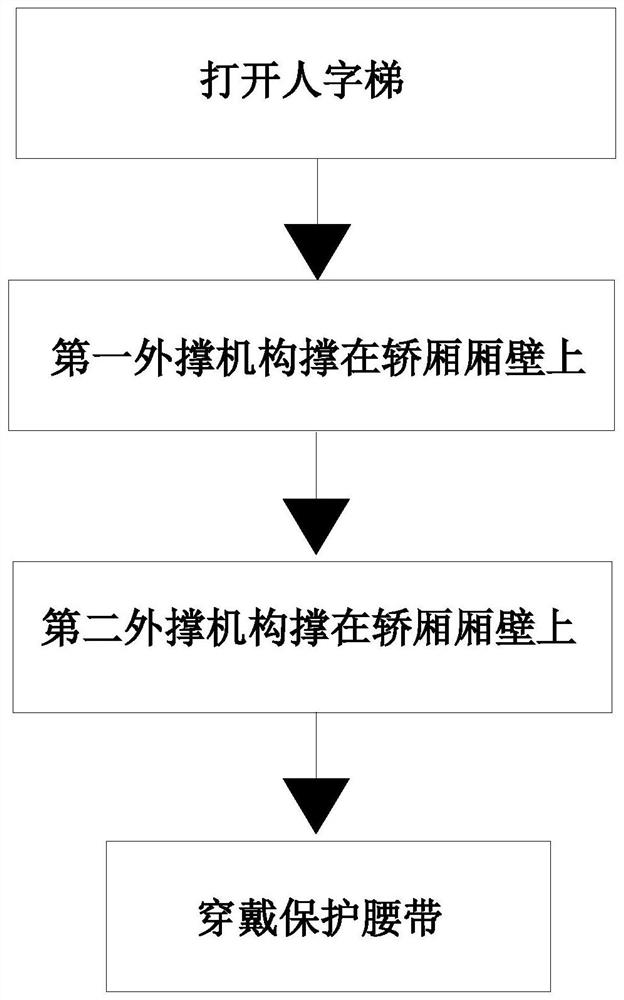

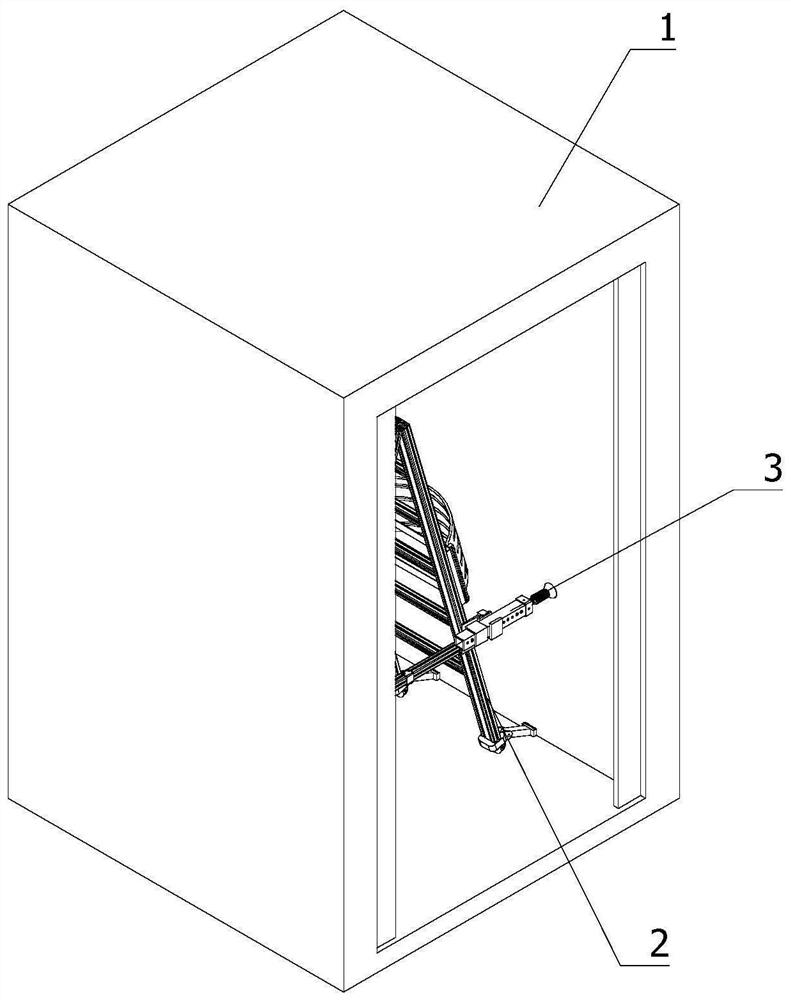

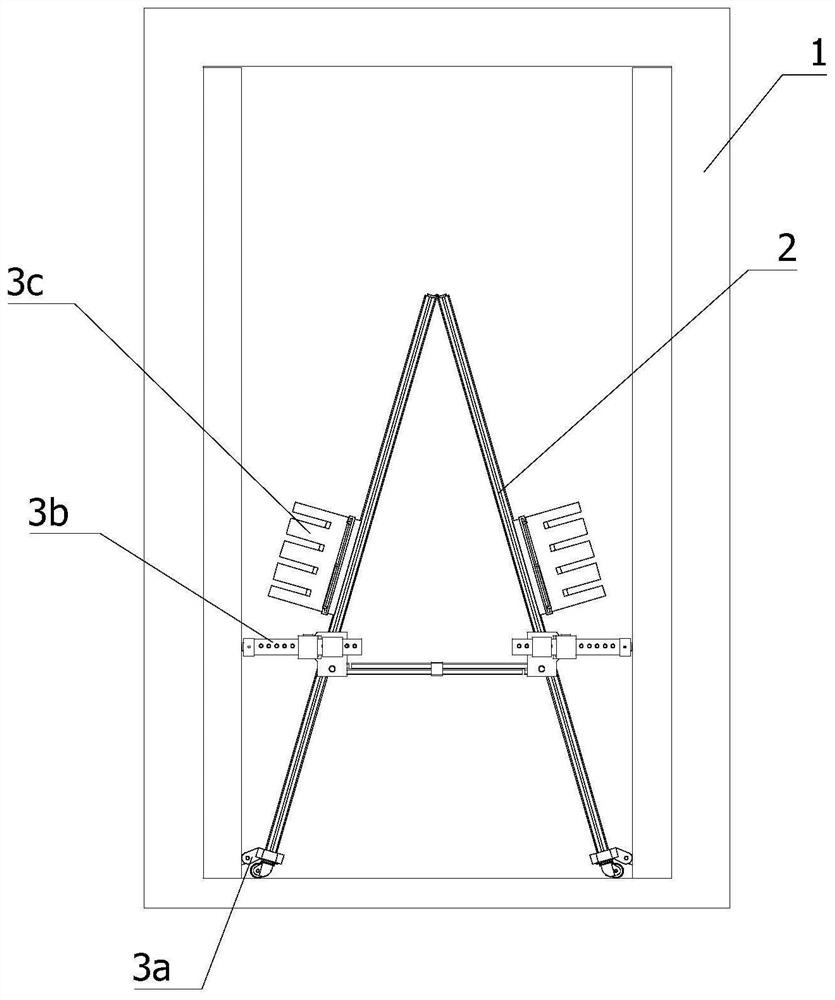

[0073] An implementation method of a safety protection device for elevator internal maintenance, the implementation method comprises the following steps:

[0074] S1, open the ladder 2 so that the first outer support mechanism 3a is against the bottom of the car 1;

[0075] S2, supporting the second outrigger mechanism 3b on the wall of the car 1;

[0076] S3, the maintenance personnel wears the protective belt 3c, and then climbs the ladder 2 to perform maintenance on the high position of the car 1.

[0077] The application realizes that the ladder 2 remains stable when the car 1 is placed by installing the first outer support mechanism 3a and the second outer support mechanism 3b on the ladder 2, and protects the belt 3c on the ladder 2. The setting ensures the stability of the maintenance personnel when climbing the ladder 2, and greatly improves the safety of the maintenance personnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com